Coated nano iron ball as well as preparation and application thereof

A technology of nano-iron and small balls, which is applied in the preparation of microspheres, microcapsule preparations, transportation and packaging, etc., which can solve the problems of easy oxidation of nano-iron, difficulty in recycling, and reduced activity, so as to achieve the goal of not being easily oxidized and reducing production costs , the effect of activity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

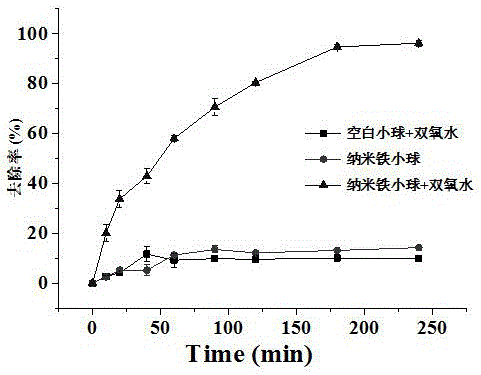

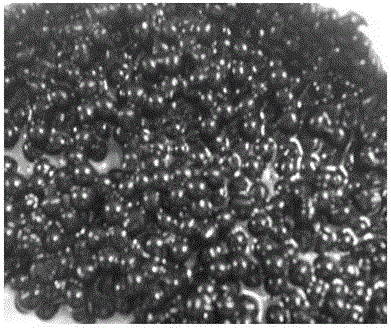

[0023] Preparation of embedded nano-iron: Wash fresh eucalyptus leaves with distilled water, dry naturally, crush them, and pass through a 40-mesh sieve; weigh 60 grams of leaf powder, add it to 1L of distilled water, and heat it in a water bath at 353K; After 1h, vacuum filter again, put the filtrate in a conical flask for later use; measure 50mL of eucalyptus extract, slowly add 1.125g of sodium alginate into it and keep stirring until the sodium alginate is completely dissolved to obtain sodium alginate Sol; stand for 30min, remove the air bubbles in the sol, and then add the newly prepared 25mL0.1mol L -1 The ferrous sulfate solution was slowly added dropwise to the sol while stirring continuously. After the solution was added dropwise, the stirring was continued for 5 minutes to obtain the sodium alginate-coated nano-iron sol; the sol was dripped into 1.33mol L -1 CaCl 2 solution, and constantly stirred with a glass rod, the sodium alginate-coated nano-iron sol in CaCl ...

Embodiment 2

[0025] Preparation of embedded nano-iron: Wash fresh mulberry leaves with distilled water, dry them naturally, crush them, and pass through a 40-mesh sieve; weigh 60 grams of leaf powder, add it to 1 L of distilled water, and heat it in a water bath at 80°C; After heating for 1 hour, vacuum filter again, and put the filtrate in a conical flask for later use; measure 50mL of eucalyptus extract, slowly add 1.125g of sodium alginate into it and keep stirring until the sodium alginate is completely dissolved to obtain alginic acid Sodium sol; let it stand for 30min, remove the air bubbles in the sol, and then add the newly prepared 25mL0.1mol·L -1 The ferrous sulfate solution was slowly added dropwise to the sol while stirring continuously. After the solution was added dropwise, the stirring was continued for 5 minutes to obtain the sodium alginate-coated nano-iron sol; the sol was dripped into 1.33mol L -1 CaCl 2 solution, and constantly stirred with a glass rod, the sodium algi...

Embodiment 3

[0027] Preparation of embedded nano-iron: wash fresh tea tree leaves with distilled water, dry naturally, crush them, and pass through a 40-mesh sieve; weigh 60 grams of leaf powder, add to 1L of distilled water, and heat in a water bath at 80°C; After heating for 1 hour, vacuum filter again, and put the filtrate in a conical flask for later use; measure 50mL of eucalyptus extract, slowly add 1.125g of sodium alginate into it and keep stirring until the sodium alginate is completely dissolved to obtain alginic acid Sodium sol; let it stand for 30min, remove the air bubbles in the sol, and then add the newly prepared 25mL0.1mol·L -1 The ferrous sulfate solution was slowly added dropwise to the sol while stirring continuously. After the solution was added dropwise, the stirring was continued for 5 minutes to obtain the sodium alginate-coated nano-iron sol; the sol was dripped into 1.33mol L -1 CaCl 2 solution, and constantly stirred with a glass rod, the sodium alginate-coated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com