Novel encoding microsphere and preparation method thereof

A coded microsphere, a new type of technology, applied in the field of composite materials, can solve the problems that the signal cannot meet the actual needs, the strength of the fluorescent signal changes, and the capacity of the code is reduced, so as to improve the stability and preparation efficiency, enhance the coating effect, The effect of increasing the encoding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

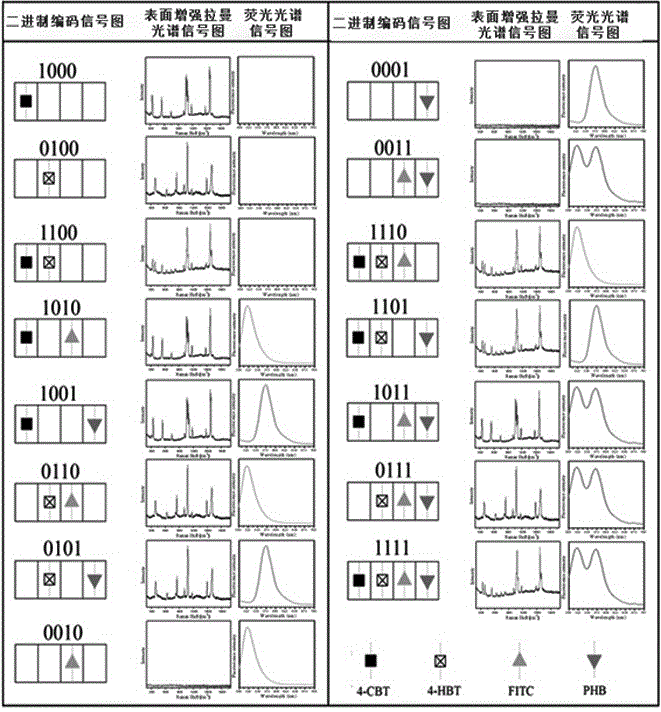

[0024] Example 1: Coded microspheres with a Raman and a fluorescent coded signal

[0025] The specific steps of its preparation are as follows:

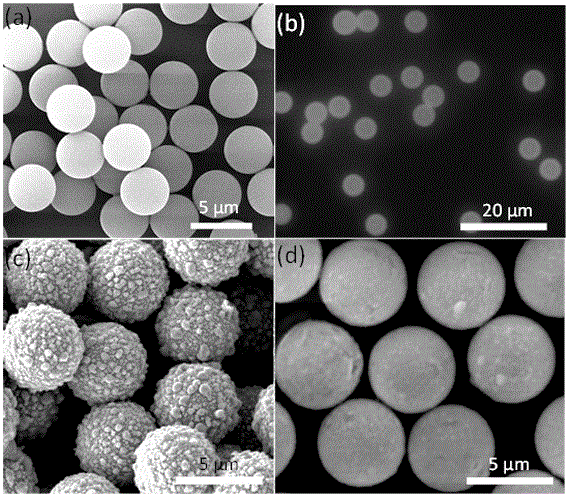

[0026] 1) Add 0.2g of melamine and 0.6g of formaldehyde to 100mL of deionized water, adjust the pH of the system to 4 with hydrochloric acid, add fluorescent probe molecules and then add 5mg of fluorescent probe molecules FITC, react for 2h and then stand still to remove the upper layer Emulsion, the obtained product was washed three times with water and ethanol, and the product was separated by centrifugation, and then dried in vacuum at 50°C to obtain monodisperse MF fluorescent microspheres with uniform size. The SEM scan and fluorescence micrographs of the microspheres are shown respectively figure 1 (A) and figure 1 (B);

[0027] 2) Add the MF fluorescent microspheres obtained in step 1) to 20mL containing AgNO 3 Add 2mg of sodium borohydride to 2mg of ethanol solution, then sonicate the mixture for 2min, then place it on a shaker, ...

Embodiment 2

[0032] Example 2: Coded microspheres with one Raman and two fluorescent coding signals

[0033] 1) Add 0.625g of melamine and 0.9g of formaldehyde to 100mL of deionized water, adjust the pH of the system to 4 with hydrochloric acid, add 30mg of fluorescent probe molecules FITC and PHB, respectively, react for 2h, then let it stand and remove the upper emulsion. The product was washed three times with water and ethanol, and the product was separated by centrifugation, and then dried under vacuum at 50°C to obtain monodisperse MF fluorescent microspheres of uniform size;

[0034] 2) Add the MF fluorescent microspheres obtained in step 1) to 20mL containing AgNO 3 To 8mg ethanol solution, add 8mg sodium borohydride, and then ultrasonically treat the mixture for 2min, then place it on a shaker, shake at 50℃ for 60min, centrifuge, wash twice with ethanol, and dry at 50℃ for 2h to obtain MF / Ag-NPs composite microspheres;

[0035] 3) Disperse 10 mg of the MF / Ag-NPs composite microspheres...

Embodiment 3

[0038] Example 3: Dual-encoded microspheres with two kinds of Raman and two kinds of fluorescent coding signals

[0039] The specific steps of its preparation are as follows:

[0040] 1) Add 3g of melamine and 2g of formaldehyde to 100mL of deionized water, adjust the pH of the system to 4 with hydrochloric acid, add 40mg of fluorescent probe molecules FITC and PHB, respectively, react for 2h and let stand to remove the upper emulsion, the resulting product is water Wash three times with ethanol, centrifuge to separate the product, and then vacuum dry at 50°C to obtain MF fluorescent microspheres of uniform size and monodisperse;

[0041] 2) Add the MF fluorescent microspheres obtained in step 1) to 20mL containing AgNO 3 Add 15mg of sodium borohydride to 10mg of ethanol solution, and then ultrasonically treat the mixture for 2min, then place it in a shaker, shake for 60min at 50℃, wash with ethanol 3 times after centrifugation, and vacuum dry at 50℃ for 2h to obtain MF / Ag-NPs co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com