Adsorption separation method of aromatic aldehydes in lignin oxidation liquid

A technology of oxidizing liquid and adsorption separation, which is applied in chemical instruments and methods, separation/purification of carbonyl compounds, preparation of organic compounds, etc., to achieve high efficiency, easy regeneration, and good selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Adsorption and separation of aromatic aldehydes according to the following steps

[0019] (1) Preparation of lignin oxidation solution: the corncob acid hydrolysis residue is added to the stainless steel reactor, and then NaOH and CuSO are added 4 , Make NaOH concentration 10%, catalyst CuSO 4 The concentration is 2%, oxygen gas is 1.0MPa, the stirring speed is 100rpm, the temperature is raised to 160°C, and the temperature is kept for 180 minutes and then cooled to room temperature. The pH value of the reaction solution is adjusted to 5 with 10% sulfuric acid to obtain the lignin oxidation solution;

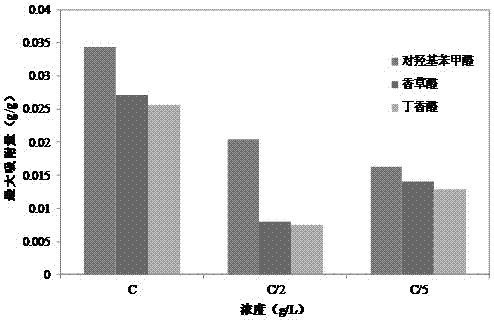

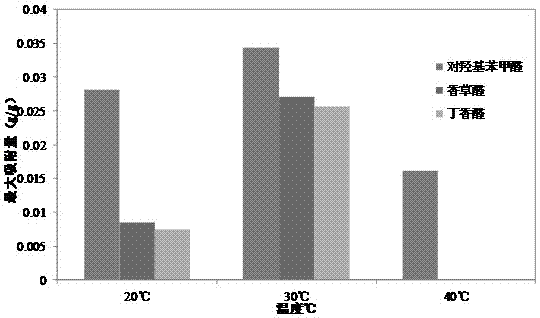

[0020] (2) Attapulgite adsorption and separation of aromatic aldehydes: The attapulgite was burned in a muffle furnace at 500°C for 4 hours and then cooled to room temperature; then the attapulgite was added to the lignin oxidation solution at a liquid-solid ratio of 50:1. Place on a shaker, 200r / min, 30°C shaking for 1 min, then filter, take the filter cake; mix the...

Embodiment 2

[0022] Example 2: Adsorption and separation of aromatic aldehydes according to the following steps

[0023] (1) Preparation of lignin oxidation solution: add the residue of enzymatic hydrolysis of corn stalk into a stainless steel reactor, and then add NaOH and CuSO 4 , Make NaOH concentration 5%, catalyst CuSO 4 The concentration is 0.5%, oxygen is fed into 0.5MPa, the stirring speed is 300rpm, the temperature is raised to 200°C, the temperature is kept for 60 minutes and then cooled to room temperature, the pH value of the reaction solution is adjusted to 6 with 10% hydrochloric acid to obtain the lignin oxidation solution;

[0024] (2) Attapulgite adsorption and separation of aromatic aldehydes: The attapulgite is burned in a muffle furnace at 700°C for 4 hours and then cooled to room temperature; then the attapulgite is added to the lignin oxidation solution at a liquid-solid ratio of 100:1, Place on a shaker, 200r / min, 30°C shaking for 10min, then filter, take the filter cake; ...

Embodiment 3

[0025] Example 3: Adsorption and separation of aromatic aldehydes according to the following steps

[0026] (1) Preparation of lignin oxidation solution: the acid hydrolysis residue of wheat straw stalk is put into a stainless steel reactor, and then NaOH and CuSO are added. 4 , Make NaOH concentration 8%, catalyst CuSO 4 The concentration is 1%, oxygen gas is 0.8MPa, the stirring speed is 200rpm, the temperature is increased to 180°C, and the temperature is kept for 120 minutes and then cooled to room temperature. The pH value of the reaction solution is adjusted to 5.5 with 10% phosphoric acid to obtain the lignin oxidation solution;

[0027] (2) Attapulgite adsorption and separation of aromatic aldehydes: The attapulgite is burned in a muffle furnace at 600°C for 4 hours and then cooled to room temperature; then the attapulgite is added to the lignin oxidation solution at a liquid-solid ratio of 75:1. Place on a shaker, 200r / min, 30℃ shaking for 5min, then filter, take the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com