Diverting acid acidizing corrosion inhibitor and preparation method thereof

A technology of acidifying corrosion inhibitor and diverting acid, which is applied in chemical instruments and methods, earthwork drilling and production, wellbore/well components, etc. It can solve the problem of affecting the uniform distribution of diverting acid, hindering the effect of temporary plugging of acid fluid, and affecting oil field production efficiency and other issues, to achieve the effect of moderate cost, significant effect, and easy purchase of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

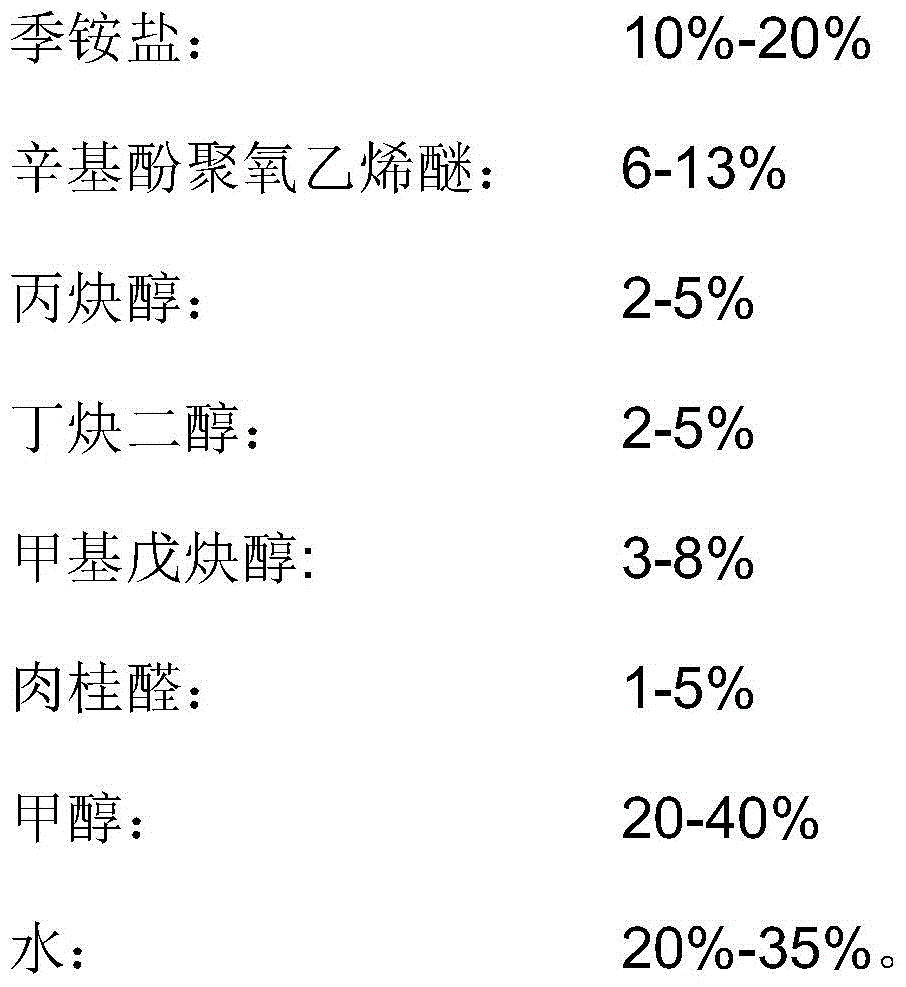

Method used

Image

Examples

Embodiment 1

[0039] Preparation of quaternary ammonium salt (mass percentage, the same below)

[0040] Complex alkylpyridine: 30%

[0041] Quinoline: 15%

[0042] Benzyl chloride: 32%

[0043] Ethylene glycol: 5%

[0044] Methanol / Ethanol: 18%

[0045] Throw in alkylpyridine, quinoline and ethylene glycol in turn, react with benzyl chloride, and keep warm at 120-140°C for 4h. After the reaction, methanol was added dropwise and stirred evenly until the reaction was completed to obtain the product quaternary ammonium salt.

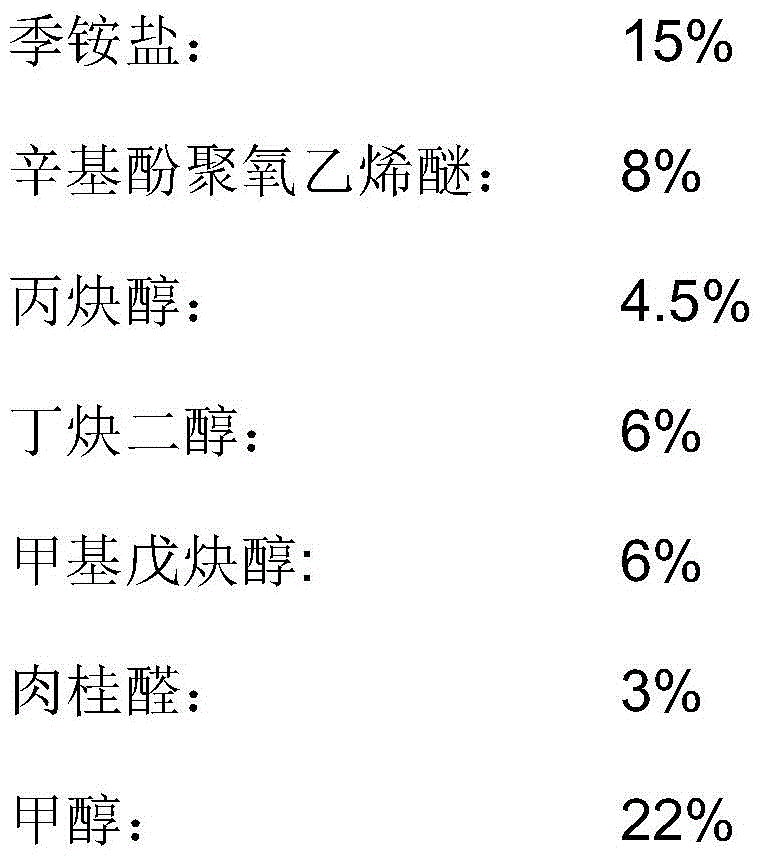

[0046] Quaternary ammonium salt: 15%

[0047] Octylphenol ethoxylate: 8%

[0048] Propylene Glycol: 4.5%

[0049] Butynediol: 6%

[0050] Methylpentynol: 6%

[0051] Cinnamaldehyde: 3%

[0052] Methanol: 22%

[0053] Water: 34.5%

[0054] With reference to the Petroleum and Natural Gas Industry Standard of the People's Republic of China "SY / T5405-1996" method, the corrosion inhibitor samples prepared in Example 1 were tested against N at different concentrati...

Embodiment 2

[0058] Preparation of quaternary ammonium salt (mass percentage, the same below)

[0059] Alkylpyridine: 30%

[0060] Quinoline: 15%

[0061] Benzyl chloride: 32%

[0062] Ethylene glycol: 5%

[0063] Methanol / Ethanol: 18%

[0064] Throw in alkylpyridine, quinoline and ethylene glycol in turn, react with benzyl chloride, and keep warm at 120-140°C for 4h. After the reaction was completed, methanol was added dropwise and stirred evenly until the reaction was completed. The product quaternary ammonium salt is obtained.

[0065] Synthetic quaternary ammonium salt: 15%

[0066] Octylphenol ethoxylate: 8%

[0067] Propylene Glycol: 4.5%

[0068] Butynediol: 6%

[0069] Methylpentynol: 6%

[0070] Cinnamaldehyde: 3%

[0071] Methanol: 22%

[0072] Water: 34.5%

[0073] With reference to the People's Republic of China Petroleum and Natural Gas Industry Standard "SY / T5405-1996" method, the corrosion inhibitor samples prepared in Example 2 were used in different hydrochlor...

Embodiment 3

[0077] Preparation of quaternary ammonium salt (mass percentage, the same below)

[0078] Alkylpyridine: 20%

[0079] Quinoline: 25%

[0080] Benzyl chloride: 32%

[0081] Ethylene glycol: 5%

[0082] Methanol / Ethanol: 18%

[0083] Throw in alkylpyridine, quinoline and ethylene glycol in turn, react with benzyl chloride, and keep warm at 120-140°C for 4h. After the reaction was completed, methanol was added dropwise and stirred evenly until the reaction was completed. The product quaternary ammonium salt is obtained.

[0084] Quaternary ammonium salt: 15%

[0085] Octylphenol ethoxylate: 10%

[0086] Propylene Glycol: 5%

[0087] Butynediol: 6%

[0088] Methylpentynol: 6%

[0089] Cinnamaldehyde: 3%

[0090] Methanol: 20%

[0091] Water: 32%

[0092] With reference to the People's Republic of China Petroleum and Natural Gas Industry Standard "SY / T5405-1996" method, the corrosion inhibitor samples prepared in Example 3 were tested against N at different concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com