Production method of bio-surfactin

A biological surface and production method technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., to achieve the effects of avoiding the reduction of biosurfactant content, high product purity, and good extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

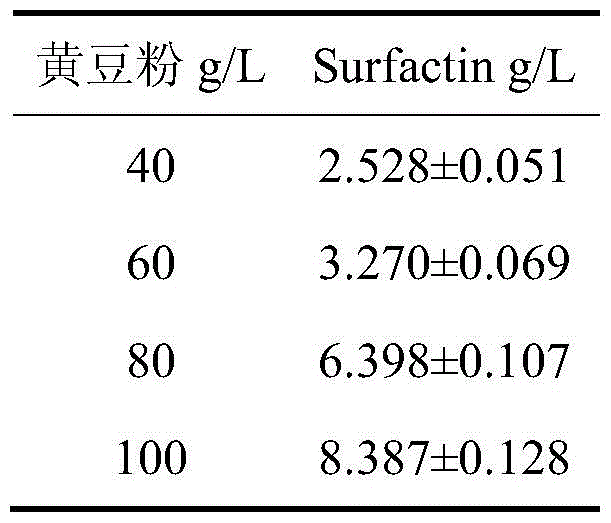

[0027] Embodiment 1: the influence of soya bean flour concentration on surfactin output

[0028] Cultivate Bacillus amyloliquefaciens fmb50 (preservation number CGMCCNo.6249) on PDA slant medium at 37°C for 24h, then inoculate a loop on BPY seed medium, culture at 37°C, 180rpm for 18h, inoculate at 3v / v% inoculum In the following medium with different carbon sources, culture at 33° C., 180 rpm for 36 hours.

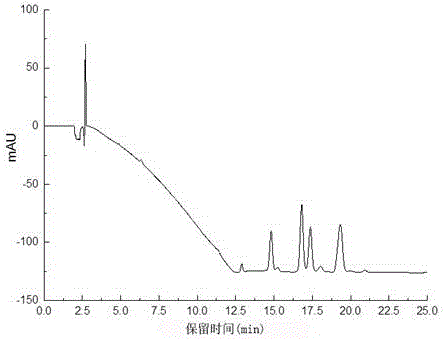

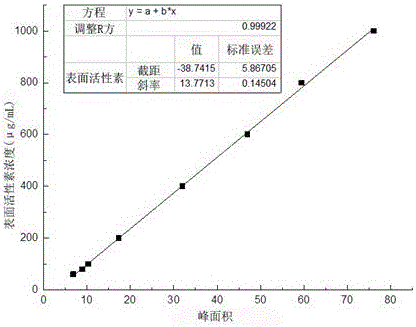

[0029] Basic components: glucose 20g / L, K 2 HPO 4 ·3H 2 O9g / L, MgSO 4 ·7H 2 O0.6g / L, CaCl 2 0.1g / L, FeSO 4 ·7H 2 O0.01g / L, MnSO 4 ·H 2 O0.05g / L, urea 1g / L, pH7.0, where glucose is sterilized alone. Add one of 40g / L, 60g / L, 80g / L, 100g / L soy flour which is sterilized separately to the above composition. Measure the content of surfactin by HPLC (its standard liquid chromatogram sees figure 1 ), and use the external standard method to calculate the amount of surfactin produced by fermentation of soybean flour with different contents (surfactin standard curve see ...

Embodiment 2

[0032] Embodiment 2: the impact of carbon source on surfactin output

[0033] Cultivate Bacillus amyloliquefaciens fmb50 (preservation number CGMCCNo.6249) on PDA slant medium at 37°C for 24h, then inoculate a loop on BPY seed medium, culture at 37°C, 180rpm for 18h, inoculate at 3v / v% inoculum In the following medium with different carbon sources, culture at 33° C., 180 rpm for 36 hours.

[0034] Basic components: soybean powder 80g / L, K 2 HPO 4 ·3H 2 O9g / L, MgSO 4 ·7H 2 O0.6g / L, CaCl 2 0.1g / L, FeSO 4 ·7H 2O0.01g / L, MnSO 4 ·H 2 O0.05g / L, urea 1g / L, pH7.0.

[0035] To the above composition was added one of the following carbon sources which were sterilized separately.

[0036] 10g / L, 20g / L, 30g / L of molasses, glucose, soluble starch, maltose syrup, maltodextrin and combinations thereof.

[0037] The culture solution was centrifuged, and surfactin in the supernatant was quantified by the following HPLC method.

[0038] The amount of surfactin produced by fermentati...

Embodiment 3

[0041] Embodiment 3: the production of surfactin in 10L fermenter

[0042] Cultivate Bacillus amyloliquefaciens fmb50 (preservation number CGMCCNo.6249) on PDA slant medium at 37°C for 24h, then inoculate a loop on BPY seed medium, culture at 37°C, 180rpm for 16h, inoculate at 1.5v / v% inoculum In the fermentation medium, cultured at 33°C for 40h, the formulation of the fermentation medium is: soybean powder 80g / L, maltodextrin 20g / L, K 2 HPO 4 ·3H 2 O9g / L, MgSO 4 ·7H 2 O0.6g / L, CaCl 2 0.1g / L, FeSO 4 ·7H 2 O0.01g / L, MnSO 4 ·H 2 O0.05g / L, urea 1g / L, emulsified silicone oil 0.5mL / L, pH7.0, among which maltodextrin was added after sterilization alone. After inoculation, adjust the air flux to 1VVM, adjust the dissolved oxygen to 100% when the speed is 180rpm, maintain the air flux to 1VVM, maintain the speed between 180 and 600rpm and keep DO>20%, during which the reduction in the fermentation broth is measured by DNS method Sugar content, when the fermentation culture r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com