Preparation method of carnosol and chitosan composite nanometer fiber mat

A technology of composite nanofibers and carnosol, applied in the direction of fiber treatment, fiber chemical characteristics, spinning solution preparation, etc., to achieve the effect of excellent antibacterial effect, easy industrialization and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

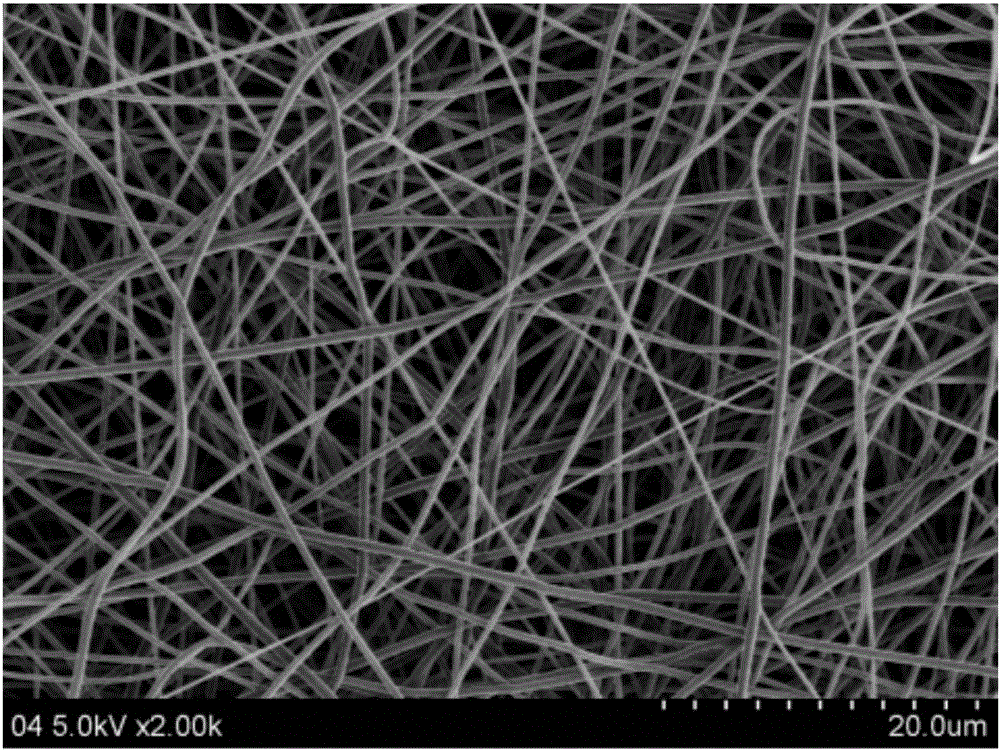

Image

Examples

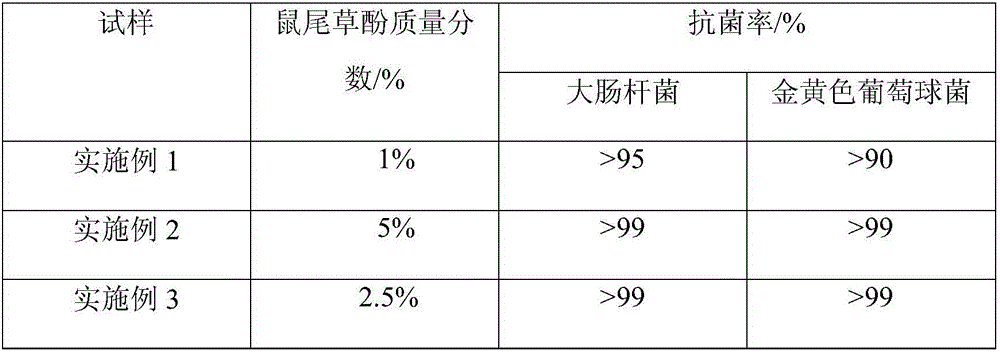

Embodiment 1

[0031] Take 2000g of dried rosemary branches and leaves, add 10L of dichloromethane, reflux extraction 3 times, each time for 3 hours, combine the extracts 3 times, concentrate and recover dichloromethane to obtain extract; dissolve the extract with 60% ethanol , remove insolubles by filtration, get 1000ml of mother liquor as adsorption solution, adsorb with 500ml AB-8 macroporous adsorption resin, elute with 1000ml purified water after completion of adsorption, then elute with 2000ml80% ethanol solution, eluent is divided into 6 section, combined 4 parts in the middle; the combined eluent was concentrated under reduced pressure to 150ml, added 200ml of water, stirred and precipitated, and left for 5 hours; centrifuged to obtain a precipitate containing carnosol; the precipitate was dissolved in 150ml of dichloromethane, and Add 200ml of petroleum ether, stir, and precipitate out; filter to obtain carnosol.

[0032] Dissolve 0.6 gram of chitosan in 15 ml of formic acid (mass v...

Embodiment 2

[0037] Take by weighing 500g of Salvia miltiorrhiza extract, dissolve with 3000ml50% ethanol, filter to remove insoluble matter, the mother liquor is adsorbed with 1000mlD101 macroporous adsorption resin, after the adsorption is completed, it is eluted with 2000ml purified water, and then eluted with 2000ml90% ethanol solution. The dehydration is divided into 6 sections, and the 4 parts in the middle are combined; the combined eluent is concentrated under reduced pressure to 500ml, added with 500ml of water, stirred and precipitated, and left for 3 hours; centrifuged to obtain a precipitate containing carnosol; precipitate with 200ml of acetic acid Dissolve the ethyl ester, add 150ml of petroleum ether therein, stir, and precipitate out; filter to obtain the active antibacterial ingredient-carnosol.

[0038] Dissolve 0.75 gram of chitosan in 15 ml of formic acid (mass volume concentration 88%), and magnetically stir until completely dissolved to obtain a chitosan solution with ...

Embodiment 3

[0043] Take 2000g of washed and dried sage, add 10L of dichloromethane, reflux extraction 3 times, each time for 3 hours, combine the extracts 3 times, concentrate and recover dichloromethane to obtain extract; extract extract with 60% ethanol Dissolve, filter to remove insoluble matter, get 1000ml mother liquor as adsorption solution, use 500ml AB-8 macroporous adsorption resin for adsorption, after the adsorption is completed, use 1000ml purified water to elute, and then use 2000ml80% ethanol solution to elute, the eluent is divided into 6 sections, combined the middle 4 parts; the combined eluate was concentrated under reduced pressure to 150ml, added 200ml of water, stirred and precipitated, and left for 5 hours; centrifuged to obtain a precipitate containing carnosol; the precipitate was dissolved in 150ml of dichloromethane, Add 200ml petroleum ether therein, stir, precipitate out; Filter to obtain active antibacterial ingredient-carnosol.

[0044] Dissolve 0.3 gram of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com