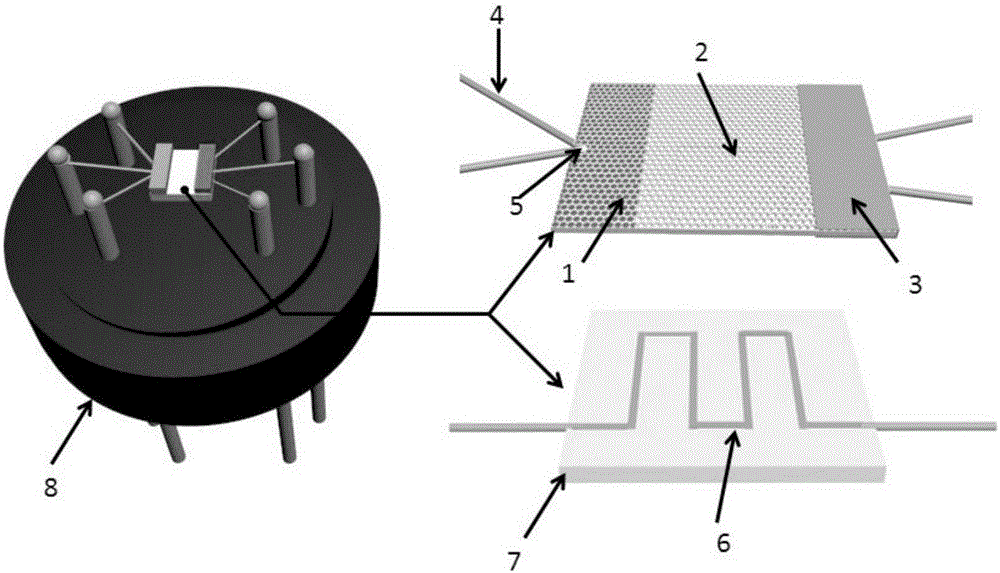

Three-phase interface YSZ-based mixed potential NO2 gas sensor with nano bowl-shaped array structure and preparation method of three-phase interface YSZ-based mixed potential NO2 gas sensor

A hybrid potential type, gas sensor technology, used in nanotechnology, instruments, scientific instruments, etc., can solve the problems of uncontrollable surface morphology, achieve good thermal stability and chemical stability, low cost, and firm bowl-shaped structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

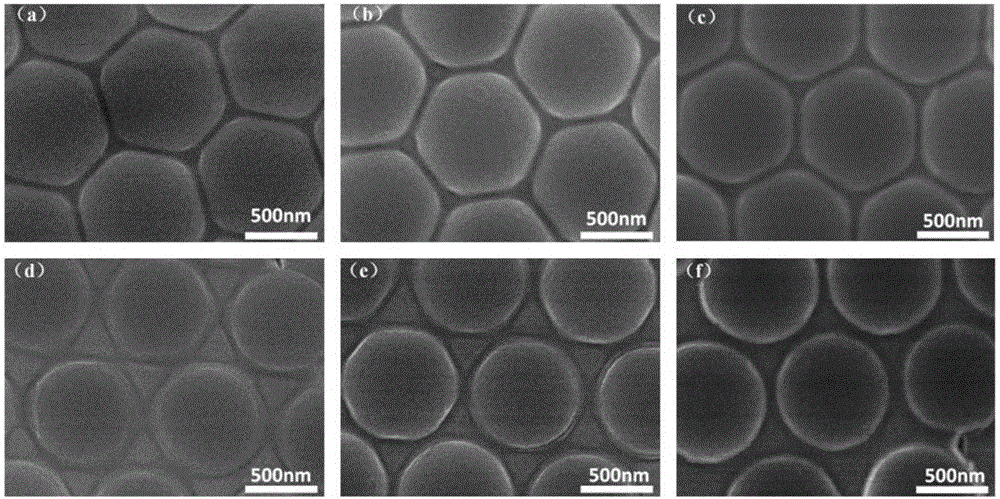

[0073] The concentration of zirconium ions in the immersion salt solution is 0.01mol / L, and the concentration of yttrium ions is 0.00175mol / L, corresponding to the structure of a nano-bowl array on the surface of the YSZ substrate, which is used as a solid electrolyte layer to build a high-efficiency three YSZ-based sensors at the phase interface.

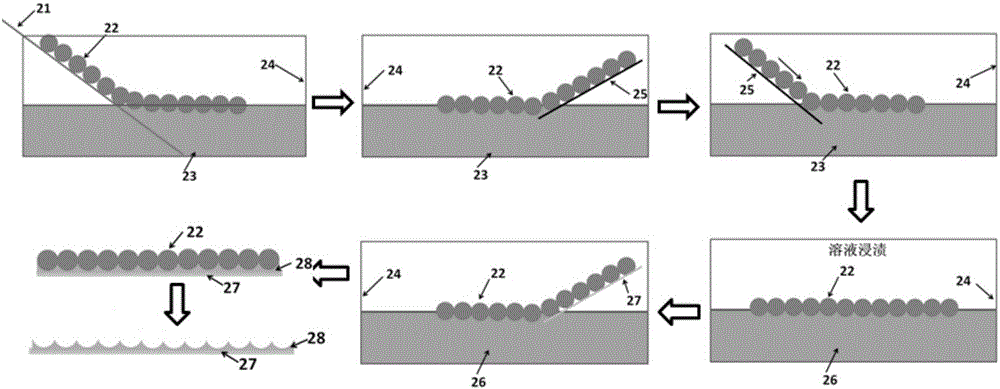

[0074] Prepare a YSZ substrate with a nanobowl-shaped array structure, the specific process is as follows:

[0075] First, inject PS microsphere suspension (diameter 1000nm, PS microsphere: ethanol: deionized water = 0.1g: 1mL: 1mL) into deionized water containing surfactant (using sodium lauryl sulfate As a surfactant (SDS), SDS: H 2 O=35μL: 100mL), the PS microspheres form a relatively neat monolayer PS microspheres on the surface of the water due to the effect of surface tension, and the PS microspheres are transferred to the saline solution using the cleaned silicon wafer for solution impregnation (ZrO (NO 3 ) 2 : Y(NO 3 )...

Embodiment 2

[0078] The concentration of zirconium ions in the immersion salt solution is 0.02mol / L, and the concentration of yttrium ions is 0.0035mol / L. Correspondingly, a nano-bowl-shaped array structure is constructed on the surface of the YSZ substrate, and this is used as a solid electrolyte layer, thereby constructing a high-efficiency Fabrication process of the YSZ-based sensor at the three-phase interface.

[0079] The production process is to change the impregnation concentration of the solution in Example 1 to 0.02 mol / L of zirconium ions and 0.0035 mol / L of yttrium ions, and the rest of the process is the same as in Example 1.

Embodiment 3

[0081] The concentration of zirconium ions in the immersion salt solution is 0.05mol / L, and the concentration of yttrium ions is 0.00875mol / L, corresponding to the structure of a nano-bowl array on the surface of the YSZ substrate, which is used as a solid electrolyte layer, and then builds a high-efficiency Fabrication process of the YSZ-based sensor at the three-phase interface.

[0082] The production process is to change the impregnation concentration of the solution in Example 1 to 0.05 mol / L of zirconium ions and 0.00875 mol / L of yttrium ions, and the rest of the process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com