Graphene based surface plasmon polariton electric-absorption light modulator

A technology of surface plasmon and optical modulators, which is applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problems of slow modulation rate and low modulation depth, and achieve the effect of increasing modulation depth, reducing relative area, and improving modulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

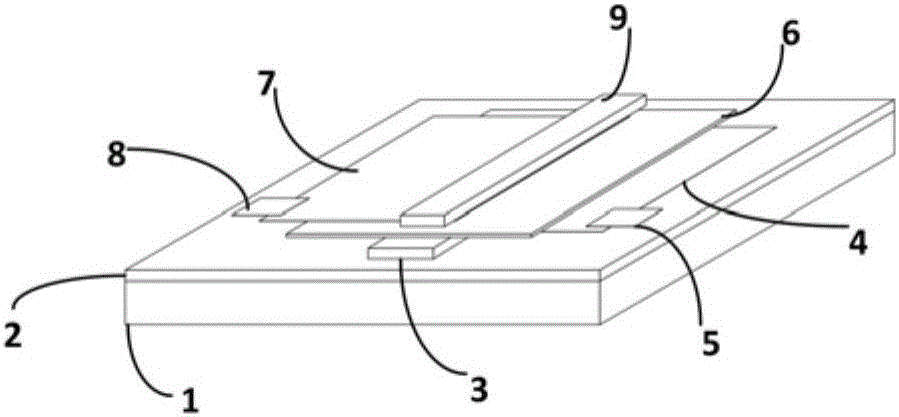

[0037] Such as Figure 1a and Figure 1bThe electroabsorption optical modulator with the structure shown includes: a silicon-based substrate 1, a silicon oxide layer 2, a semiconductor nanoribbon waveguide 3, a single-layer graphene 4, a lower electrode 5, an aluminum oxide dielectric layer 6, and a single-layer graphene 7 , electrode 8 and metal silver waveguide 9. Wherein, the semiconductor nanoribbon waveguide 3 is placed on a silicon-based substrate 1 with a silicon oxide layer 2 of a certain thickness. A single layer of graphene 4 is transferred to the semiconductor nanoribbon waveguide 3, and the graphene on one side is removed by ion beam etching technology. Then on the graphene layer, the lower electrode 5 is prepared by photolithography. Next, thermal evaporation or magnetron sputtering is used to plate an aluminum oxide dielectric layer 6 with a thickness of 10 nm to 100 nm, and the plated dielectric layer cannot completely cover the lower electrode. After the coa...

Embodiment 2

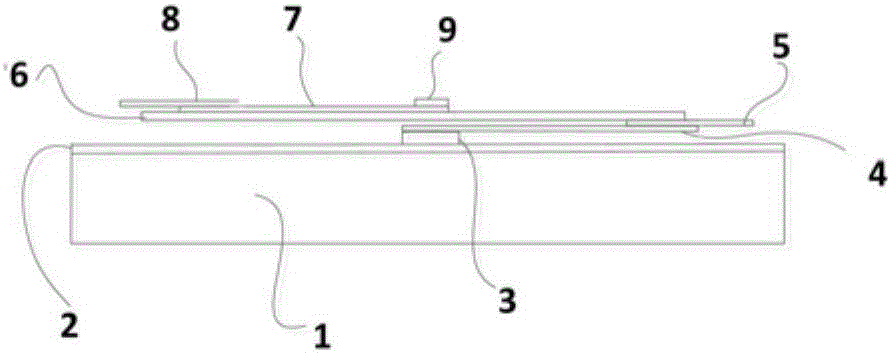

[0039] Such as Figure 2a and Figure 2b The electroabsorption optical modulator of the shown structure includes: a silicon-based substrate 21, a silicon oxide layer 22, a semiconductor nanoribbon waveguide 23, a lower electrode 24, an aluminum oxide dielectric layer 25, a single-layer graphene 26, an electrode 27 and metallic silver waveguide 28.

[0040] Compared with Embodiment 1, in order to reduce the requirements of the manufacturing process, the lower layer of graphene is no longer placed, and the lower electrode 24 is directly connected to the lower semiconductor nanoribbon waveguide 23 by means of photolithography. At the same time, this structure can no longer use the ion beam etching technology to etch the upper single-layer graphene 26 .

Embodiment 3

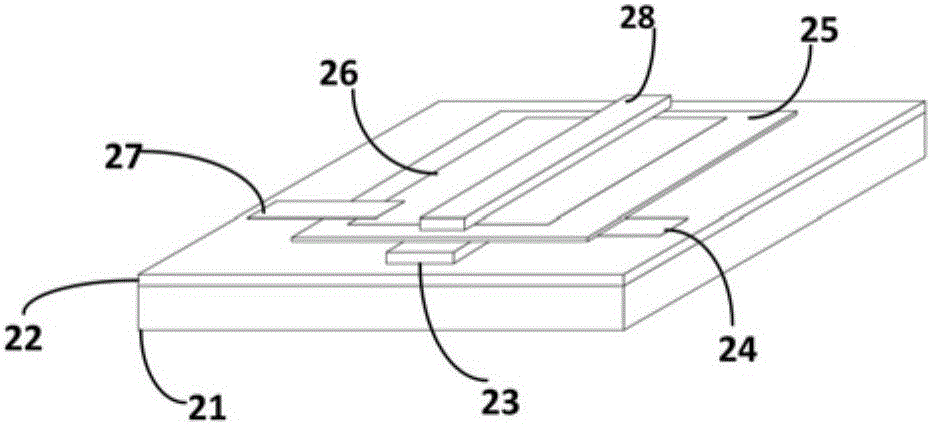

[0042] Such as Figure 3a and Figure 3b The electroabsorption optical modulator of the structure shown includes: a silicon-based substrate 31, a silicon oxide layer 32, a metal waveguide 33, a single-layer graphene 34, a lower electrode 35, an aluminum oxide dielectric layer 36, a single-layer graphene 37, an electrode 38 and metal waveguide 39.

[0043] Compared with Embodiment 1, both the upper and lower waveguides are made of metal. This structure is designed to generate SPP waves at both the upper and lower interfaces, and the metal acts as a mirror at the interface, which has a better reflection effect, but the non-modulated absorption loss of the metal will be greater. The metal waveguide 33 is placed on the silicon-based substrate 31 with a certain thickness of the oxide layer 32, and the single-layer graphene 34 is placed on the metal waveguide by transfer, and the graphite on the redundant side is removed by ion beam etching and other means alkene. Afterwards, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com