Debitterized natural rose residue extract and preparing method and application thereof

A technology of rose dregs and rose flowers, which is applied in the direction of food ingredients containing natural extracts, application, food ingredients as antioxidants, etc., can solve the problems of difficult removal of bitter and astringent substances, long cycle, time-consuming and labor-intensive, etc., to achieve rich products Effects of improving flavor, increasing added value, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

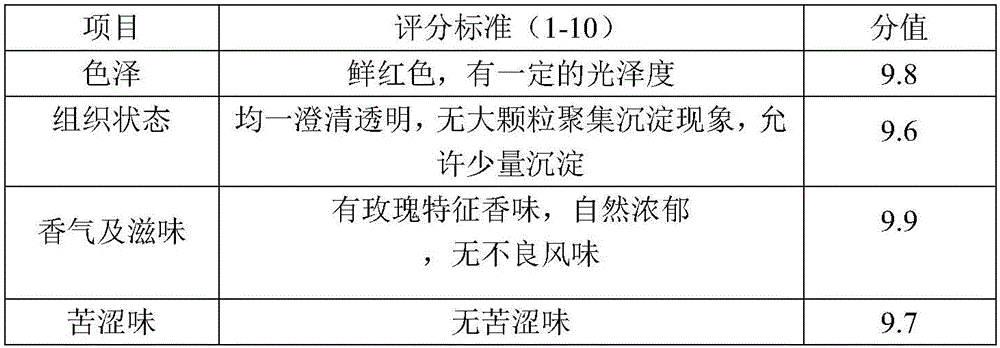

Embodiment 1

[0039] (1) Fresh half-open Pingyin roses are selected for picking, and the picked flowers are frozen and pretreated at -10°C for 10 hours. Rinse the above-mentioned pretreated flowers in clean water to remove floating dust and insects on the surface of the flowers, remove and drain the water for later use.

[0040] (2) Put the above-mentioned pretreated flowers in a distiller and mix them with water at a mass ratio of 1:5, distill for 4 hours to extract the essential oil, after the distillation is completed, wait for the distiller to cool down naturally, filter and separate the flower residue and flower water in the bottle .

[0041] (3) Mix the filtered flower dregs with water at a mass ratio of 1:4, ultrasonically extract at 40°C for 30 minutes, extract the active ingredients in the flower dregs, filter and separate the flower dregs and flower water, repeat the extraction twice, and combine the filtrates , and then concentrated by rotary evaporation to obtain the flower res...

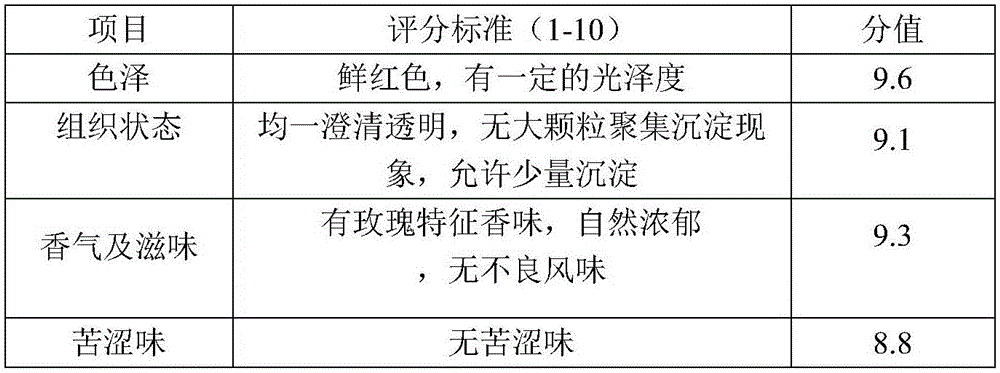

Embodiment 2

[0051] (1) Fresh half-bloomed Gansu Kushui roses were selected for picking, and the picked flowers were frozen and pretreated at -18°C for 4 hours. Rinse the above-mentioned pretreated flowers in clean water to remove floating dust and insects on the surface of the flowers, remove and drain the water for later use.

[0052] (2) Put the above-mentioned pretreated flowers in a distiller and mix them with water at a mass ratio of 1:4, distill for 3 hours to extract the essential oil, after the distillation is completed, wait for the distiller to cool down naturally, filter and separate the flower residue and flower water in the bottle .

[0053] (3) Mix the filtered flower dregs with water at a mass ratio of 1:6, ultrasonically extract at 50°C for 40 minutes, extract the active ingredients in the flower dregs, filter and separate the flower dregs and flower water, repeat the extraction twice, and combine the filtrates , and then concentrated by rotary evaporation to obtain a flo...

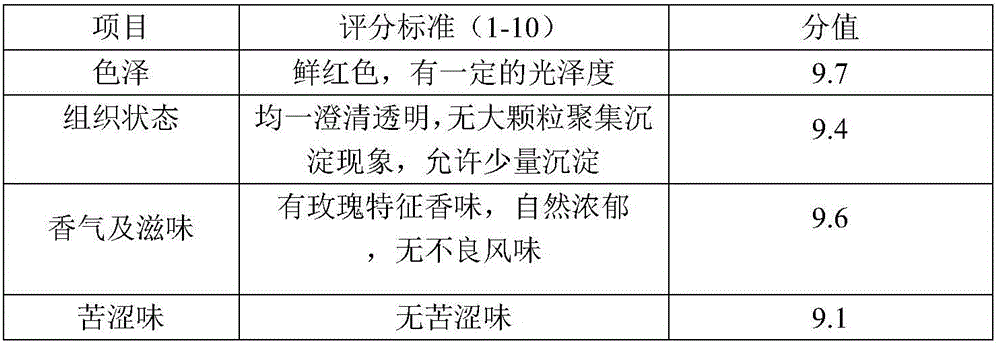

Embodiment 3

[0063] (1) Fresh half-open Pingyin roses are selected for picking, and the picked flowers are frozen and pretreated at -5°C for 15 hours. Rinse the above-mentioned pretreated flowers in clean water to remove floating dust and insects on the surface of the flowers, remove and drain the water for later use.

[0064] (2) Put the above-mentioned pretreated flowers in a distiller and mix them with water at a mass ratio of 1:6, distill for 4 hours to extract essential oils, and after the distillation is completed, wait for the distiller to cool naturally and filter to separate the flower residue and flower water in the bottle.

[0065] (3) Mix the filtered flower dregs with water at a mass ratio of 1:5, ultrasonically extract at 45°C for 25 minutes, extract the active ingredients in the flower dregs, filter and separate the flower dregs and flower water, repeat the extraction twice, and combine the filtrates , and then concentrated by rotary evaporation to obtain a flower residue ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com