Papermaking auxiliary agent mixture and preparation method

A technology for papermaking aids and mixtures, which is applied in the fields of papermaking aids mixtures and preparation methods, can solve the problems of poor use effect and cannot be effectively improved, and achieves the effects of reducing dosage, improving mechanical strength and improving fiber structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

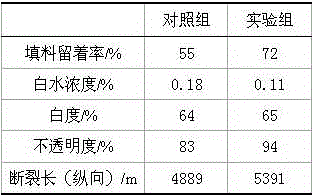

Image

Examples

Embodiment 1

[0022] Example 1 A mixture of papermaking auxiliary agents, mainly prepared from the following raw materials (5 kg each): 12 parts of carboxymethyl cellulose, 14 parts of mica powder, 20 parts of pottery clay, 2 parts of polyethylene glycol, polyethylene wax 1 part, 1 part of propylene glycol butyl ether, 2 parts of nonylphenol polyoxyethylene ether, 2 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, 1 part of paraben, 2 parts of white wax, 1.2 parts of azodicarbonamide, three 1 part of sodium polyphosphate, 2 parts of lactitol. The preparation method of above-mentioned a kind of papermaking aid mixture is:

[0023] (1) Take mica powder and pottery clay in a grinder, grind for 20 minutes to make raw material powder, pass through a 150-mesh sieve, add water and stir to remove impurities, and heat and dry;

[0024] (2) Mix carboxymethyl cellulose, polyethylene glycol and sodium tripolyphosphate, place in a stirring container, add water 4 times the mass of raw ma...

Embodiment 2

[0026] Example 2 A mixture of papermaking auxiliary agents, mainly prepared from the following raw materials (5 kg each): 20 parts of carboxymethyl cellulose, 20 parts of mica powder, 30 parts of pottery clay, 5 parts of polyethylene glycol, polyethylene wax 4 parts, 3 parts of propylene glycol butyl ether, 4 parts of nonylphenol polyoxyethylene ether, 5 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, 2 parts of paraben, 5 parts of white wax, 2 parts of azodicarbonamide, three parts 4 parts of sodium polyphosphate, 4 parts of lactitol. The preparation method of above-mentioned a kind of papermaking aid mixture is:

[0027] (1) Take mica powder and pottery clay in a grinder, grind for 30 minutes to make raw material powder, pass through a 350-mesh sieve, add water and stir to remove impurities, and heat and dry;

[0028] (2) Mix carboxymethyl cellulose, polyethylene glycol and sodium tripolyphosphate, place in a stirring container, add water 7 times the mass o...

Embodiment 3

[0030] Example 3 A mixture of papermaking auxiliary agents, mainly prepared from the following raw materials (5 kg each): 14 parts of carboxymethyl cellulose, 16 parts of mica powder, 22 parts of pottery clay, 3 parts of polyethylene glycol, polyethylene wax 2 parts, 1.5 parts of propylene glycol butyl ether, 2.5 parts of nonylphenol polyoxyethylene ether, 3 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, 1.2 parts of paraben, 3 parts of white wax, 1.4 parts of azodicarbonamide, three 2 parts of sodium polyphosphate, 2.5 parts of lactitol. The preparation method of above-mentioned a kind of papermaking aid mixture is:

[0031] (1) Take mica powder and pottery clay in a grinder, grind for 20 minutes to make raw material powder, pass through a 200-mesh sieve, add water and stir to remove impurities, and heat and dry;

[0032] (2) Mix carboxymethyl cellulose, polyethylene glycol and sodium tripolyphosphate, place in a stirring container, add water 5 times the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com