Enhanced-mode high electron mobility transistor, preparation method thereof, and semiconductor device

A high electron mobility, enhanced technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of increasing device leakage and reducing device breakdown voltage, so as to improve breakdown voltage and reduce leakage , the effect of reducing surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

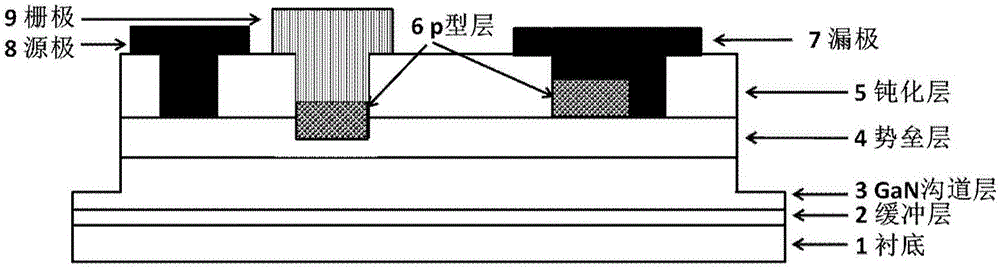

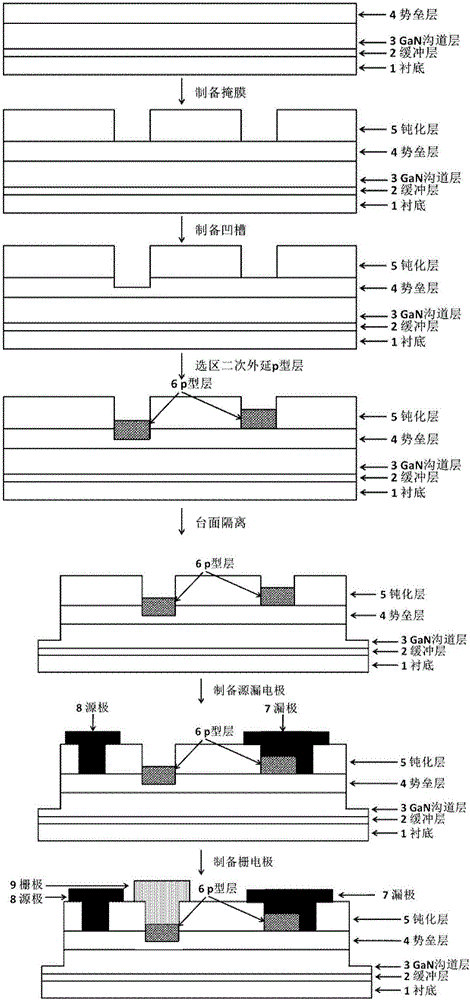

[0046] Based on the same inventive concept, the present invention provides a method for preparing an enhanced high electron mobility transistor, comprising the following steps:

[0047] S1: Prepare an epitaxial layer on the substrate, including preparing a barrier layer;

[0048] S2: depositing a passivation layer on the barrier layer;

[0049] S3: Preparing a secondary epitaxial mask for selected areas;

[0050] S4: In the local area of the secondary epitaxial mask of the selected area, etch down from the barrier layer to prepare grooves;

[0051] S5: growing a p-type layer on the selective secondary epitaxial mask region and the groove;

[0052] S6: Prepare the source and drain electrodes, wherein the drain electrode is in contact with the p-type layer metal grown on the non-groove;

[0053] S7: preparing a gate electrode on the surface of the p-type layer grown in the groove.

[0054] Preferably, the doping concentration of the p-type layer is 1×10 16 -1×10 22 cm -3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

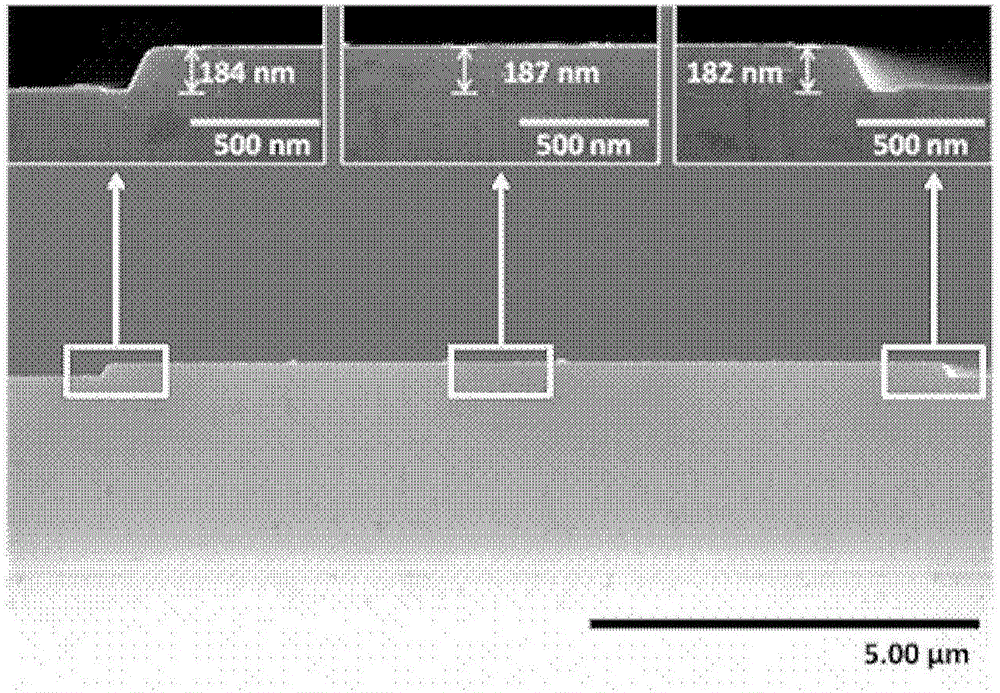

| Etching depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com