Porous hollow fiber membrane and method for manufacturing same

A manufacturing method and porous technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as difficulty in taking into account mechanical strength, complex manufacturing methods of filtration membranes, molecular clogging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

[0200] Another preferred embodiment of this embodiment will be described below.

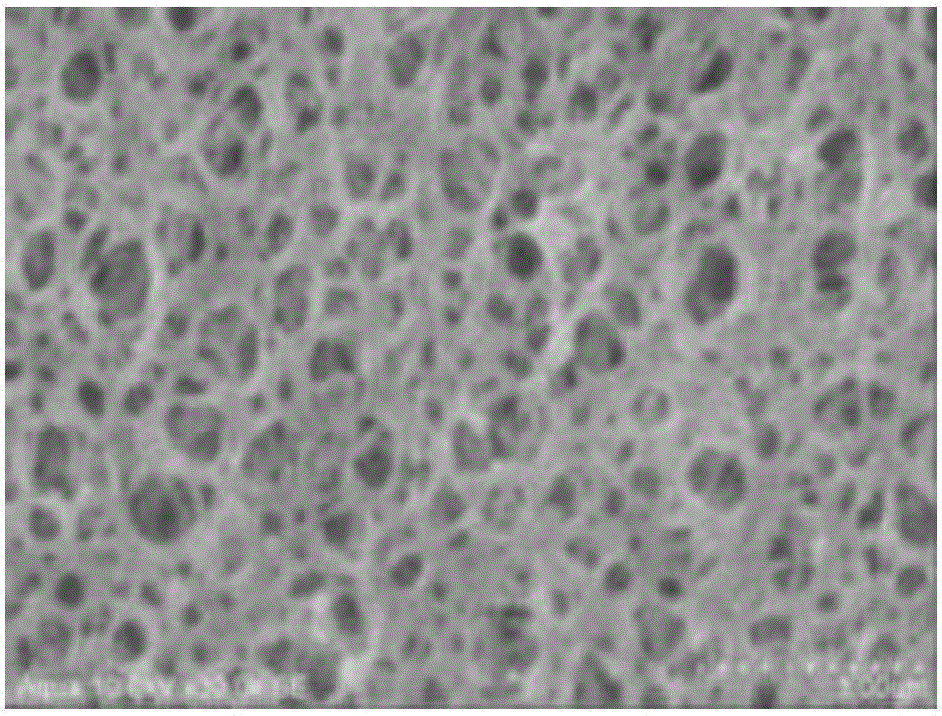

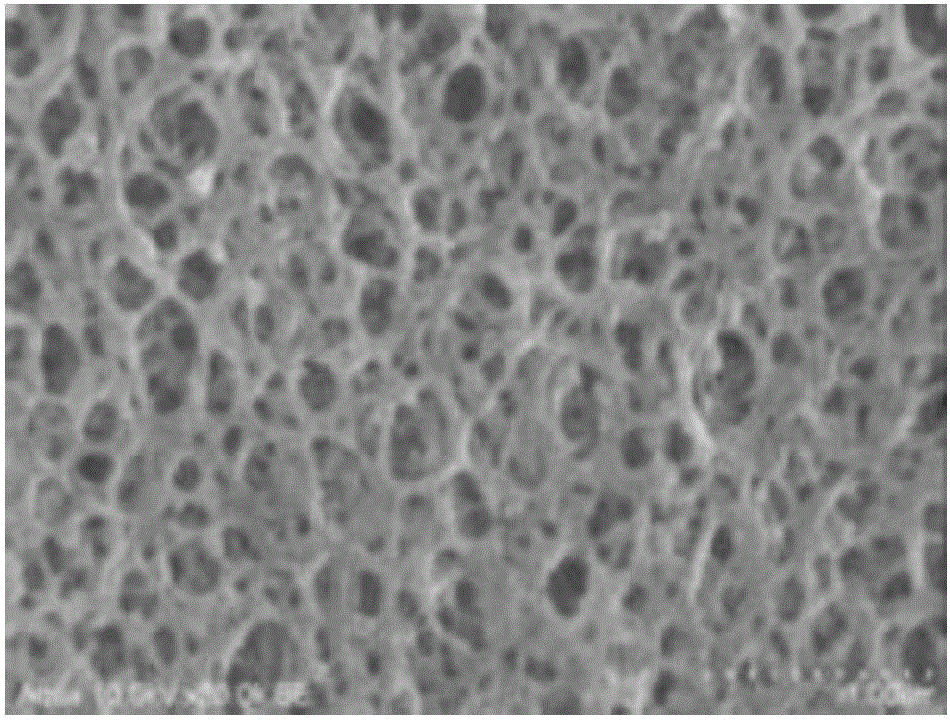

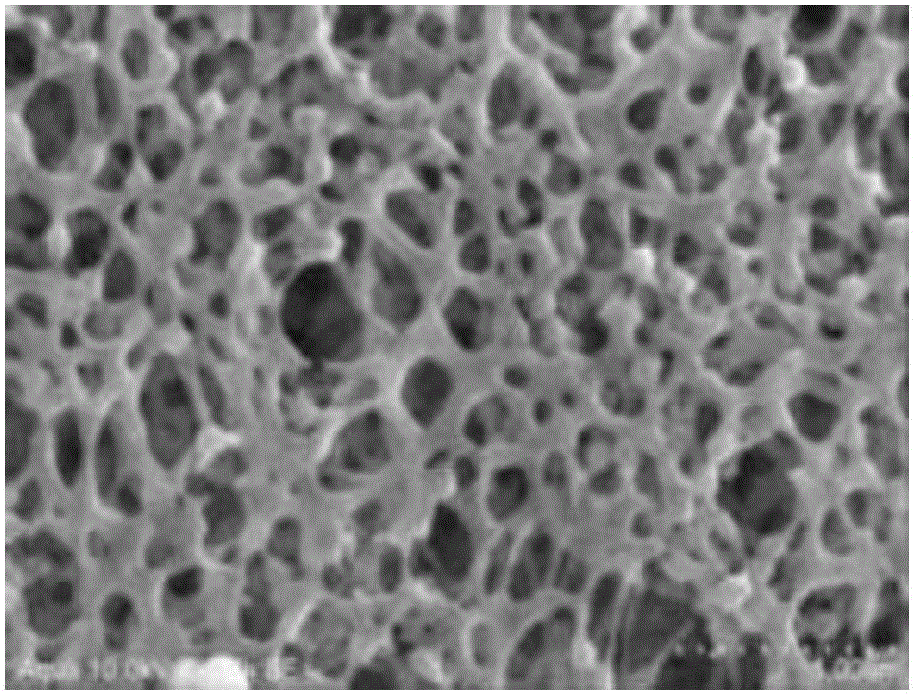

[0201] The hollow porous hollow fiber membrane of the present embodiment is a porous hollow fiber membrane in which, in the cross-sectional structure when cut in the thickness direction and observed, a layer from the surface to a depth of 1 μm (hereinafter referred to as a porous layer The ratio of the average pore size Ad of A.) to the size of the layer from a depth of 2 μm to 3 μm (hereinafter referred to as porous layer B.) Bd is 0.6 or less, preferably 1 / 2 or less (0.5 or less).

[0202] Here, the porous hollow fiber membrane of the present embodiment is characterized in that the membrane having the layer with the smallest pore diameter in the porous layer A forming the outer surface is substantially less than 1 μm, and extremely minute substances falling off the outer surface and / or Soluble organic polymers are not easy to clog inside the membrane.

[0203] Further, the porous hollow fiber ...

Embodiment 1

[0333] As the yarn for the hollow reinforcing support, polyester fiber (polyethylene terephthalate (PET), fineness: 84 dtex, filament number: 36, false twist (falsewisting) yarn) was used. As for the bobbins used in the production of the hollow reinforcement support, five bobbins wound with 5 kg of polyester fiber were prepared, and as a circular knitting machine (maru knitting machine), a desktop rope knitting machine (Takushang type knitting machine) was used (Sonoi Manufactured by Textile Machinery Co., Ltd., knitted fabric (meias) needle count: 12, needle size: 16 needle count (gauge, ゲージ), spindle diameter: 8mm). Nelson rolls (Nelson roll, Nelson Roll) were used as the rope supply device and the take-up device. As the heating die, a stainless steel die (outer diameter D: 5 mm, inner diameter d: 2.5 mm, length L: 300 mm) having a heating unit was used.

[0334] Five polyester fibers pulled out from the bobbin were combined into one fiber (total fineness; 420 dtex), and ci...

Embodiment 2

[0347] As the first and the second film-forming resin solutions, polyvinylidene fluoride (manufactured by Arkema, trade name Kynar761A) 19% by mass and polyvinylpyrrolidone (manufactured by Nippon Shokubai Co., Ltd., trade name K-80) mass A film-forming resin solution obtained by dissolving 12% in 69% by mass of N,N-dimethylacetamide while stirring. As a coagulation solution, 20% by mass of N,N-dimethylacetamide was used as a non-solvent A porous hollow fiber membrane was obtained in the same manner as in Example 1 except that pure water as a component was a coagulation solution having a composition of 80% by mass.

[0348] The viscosity of this film-forming resin solution at 40° C. was 250,000 mP·s.

[0349] Moreover, the average pore diameter of each layer was calculated similarly to Example 1 about the obtained porous hollow fiber membrane. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com