Preparation method of astaxanthin particles and application thereof in cigarette filter sticks

A technology of astaxanthin and granules, which is applied in applications, e-liquid filter elements, tobacco, etc., to achieve good application prospects, wide sources, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

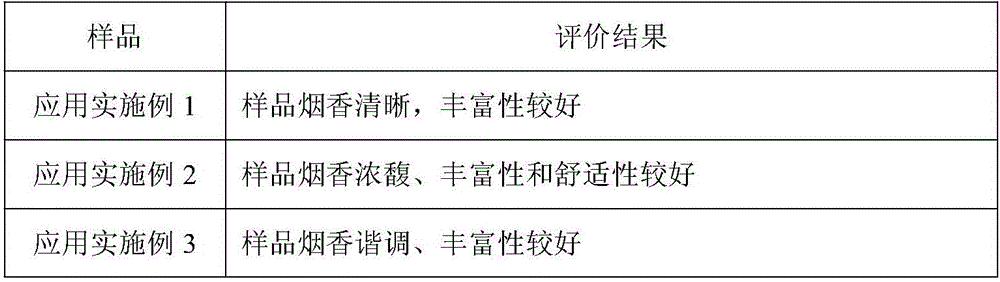

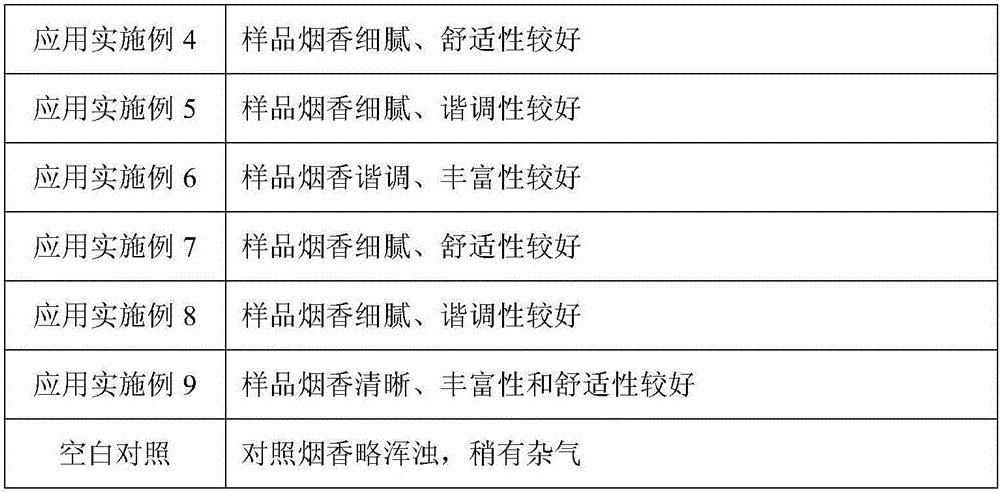

Examples

Embodiment 1

[0020] Weigh 60 parts of astaxanthin powder, 10 parts of tobacco powder, and 1 part of sodium carboxymethylcellulose in parts by weight, and mix evenly; weigh 5 parts of apple extract, 100 parts of water, and mix with astaxanthin powder, tobacco The powder and the mixed powder of sodium carboxymethyl cellulose are uniformly mixed to prepare a soft material. Extruding the soft material through a spheronizer to prepare shaped granules, drying the granules in an oven at 60° C., and sieving to obtain 20-60 mesh astaxanthin granules with a water content of 6%.

Embodiment 2

[0022] Take by weight 65 parts of astaxanthin powder, 15 parts of tobacco powder, and 0.3 part of chitosan, and mix evenly; weigh 1 part of jujube extract, 120 parts of 10% ethanol aqueous solution, and mix with astaxanthin powder, tobacco The powder powder and the mixed powder of chitosan are evenly mixed to prepare a soft material. Extruding the soft material through a spheronizer to prepare shaped granules, drying the granules in an oven at 65° C., and sieving to obtain 20-60 mesh astaxanthin granules with a moisture content of 6.5%.

Embodiment 3

[0024] Take by weight 70 parts of astaxanthin powder, 20 parts of tobacco powder, and 20 parts of polyvinyl alcohol and mix evenly; weigh 10 parts of honeysuckle extract, 5 parts of jujube extract, 160 parts of 70% ethanol, and mix with astaxanthin The mixed powder of plain powder, tobacco powder and polyvinyl alcohol is evenly mixed to prepare a soft material. The soft material is passed through a swing granulator to prepare shaped granules, the granules are dried in an oven at 80° C., and sieved to obtain 20-60 mesh astaxanthin granules with a water content of 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com