Application of high-dispersity hybridization antibacterial agent in aspect of ultrafiltration membrane improvement

A high-dispersibility, antibacterial agent technology, applied in the field of nanomaterial technology application, can solve the problems of high requirements, complicated process, cumbersome separation membrane process, etc., and achieve the effect of good dispersion, excellent performance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

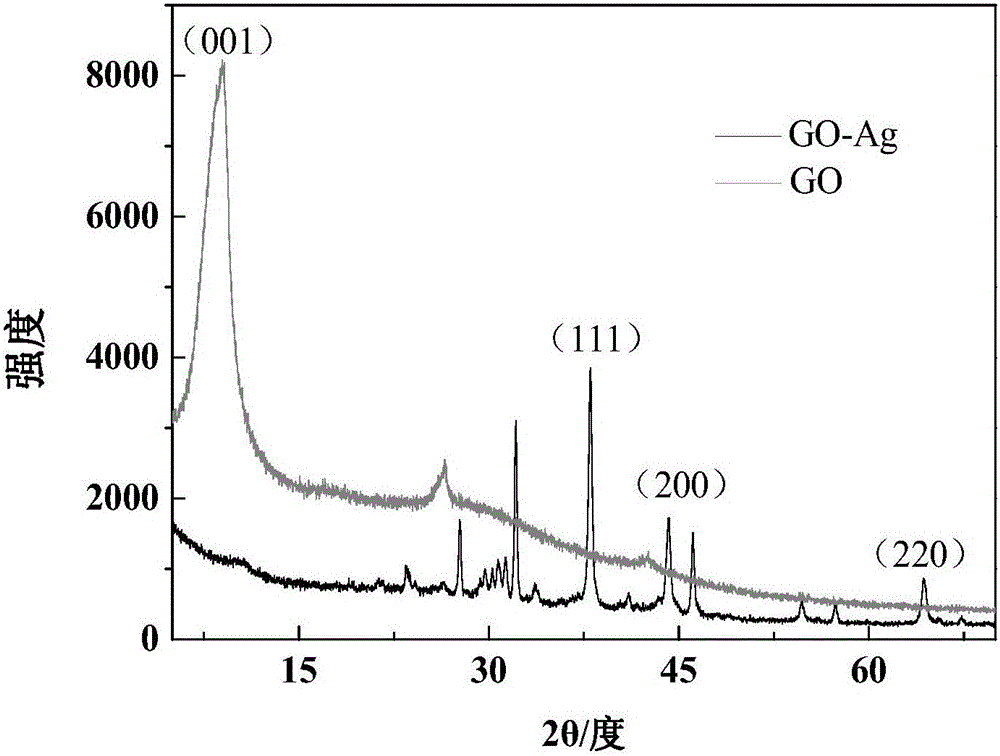

[0030] Take 50mL, 1mg / mL graphene oxide / water dispersion and sonicate for 0.5h, then add 50mL, 2×10 -3 mol / L AgNO 3 Solution, after ultrasonication for 0.5h, add water to dilute to 250mL, then add 5mL, 0.1mol / L KOH solution to the above mixture, react in an oil bath at 90°C for 2h under magnetic stirring, the color of the solution changes from brown to yellowish brown, then keep warm at 60°C a period of time. The obtained solution was centrifuged, washed and dried to obtain the nanocomposite antibacterial agent GO-Ag. figure 1 It is the XRD pattern of GO and GO-Ag obtained in Example 1. The prepared graphene oxide and GO-Ag are composed of X-ray diffraction analysis characteristic diffraction peak crystal images, and the scanning range is 2θ=0~70°. The XRD of GO is in The (001) crystal plane characteristic peak appears around 2θ=10°, and the (111)(200)(220) crystal plane characteristic peak of nano-silver appears at 2θ=37°, 45°, and 57° in XRD of GO. Prove the successful pr...

Embodiment 2

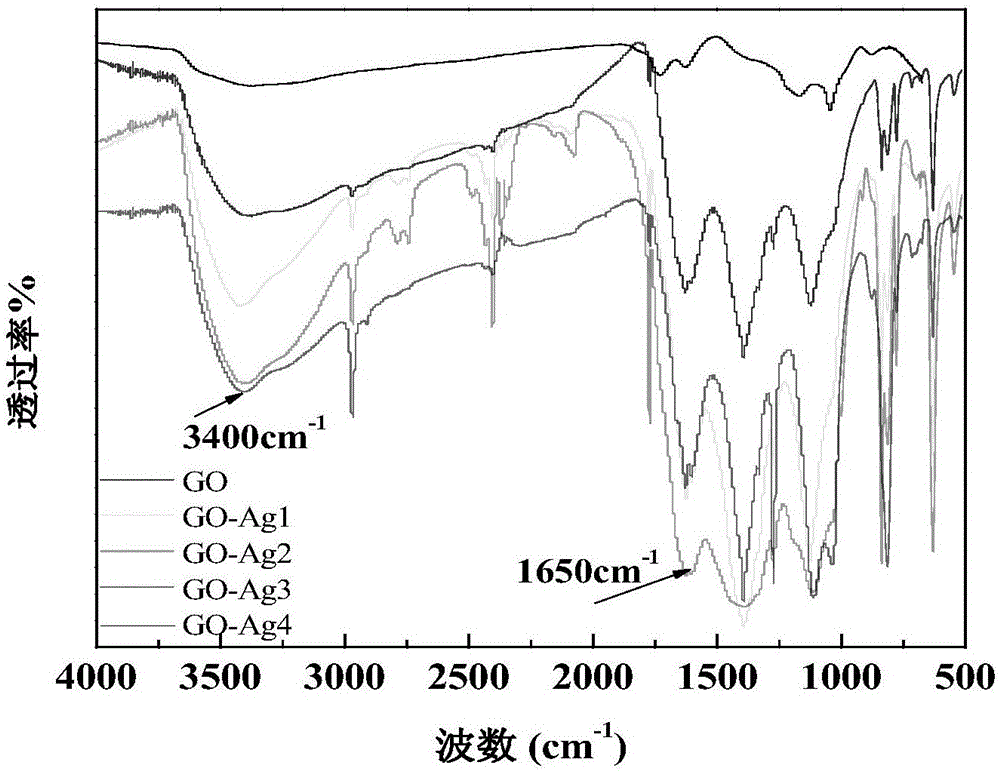

[0032] Implementation steps are the same as in Example 1, AgNO 3 The volume of the solution is 100mL, 2×10 -3 mol / L, ultrasonic time 1.5h, the volume of KOH solution is 7mL, 0.1mol / L. figure 2 The GO-Ag2 curve in the middle is the infrared spectrogram of the material obtained in Example 2.

Embodiment 3

[0034] Implementation steps are the same as in Example 1, AgNO 3The volume of the solution is 100mL, 2×10 -3 mol / L, the amount of KOH solution is 7mL, 0.1mol / L, 100°C oil bath reaction for 1.5h. figure 2 The GO-Ag3 curve in the middle is the infrared spectrogram of the material obtained in Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com