A kind of preparation method of synthetic gas methanation to produce natural gas catalyst

A catalyst and natural gas technology, which is applied in the field of preparation of supported molybdenum-based catalysts for synthesis gas methanation to natural gas, can solve the problems of increased catalyst preparation costs, little contribution to the target reaction of catalysts, low metal utilization rate of carrier channels, etc., to achieve improved Conversion rate and product selectivity, avoiding further conversion, and accelerating the effect of adsorption and desorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

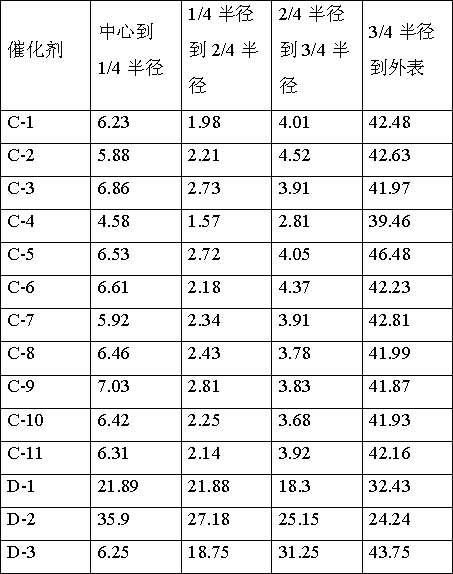

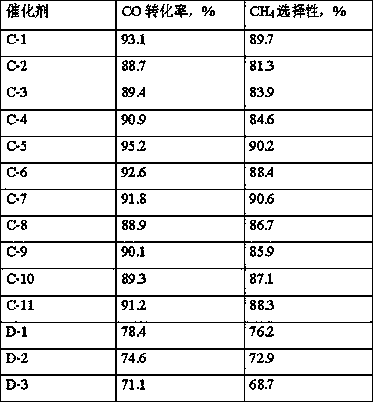

Embodiment 1

[0028]Weigh 1.84g of ammonium molybdate and 1.98g of nickel nitrate and dissolve them in an appropriate amount of deionized water to obtain solution A; adopt the equal volume impregnation method to load on 20g of alumina (the pore volume is 0.72ml / g, the specific surface area is 242m 2 / g, strip shape, equivalent diameter 1.5mm) carrier, aged at room temperature for 4h, dried at 80°C for 12h, and calcined at 500°C for 4h to obtain catalyst precursor B, in which Mo accounted for 5% of the weight of the carrier by element, and Ni by element Accounting for 2% of the weight of the carrier; catalyst precursor B is activated in a mixed atmosphere containing hydrogen, the volume content of hydrogen in the mixed gas is 80%, the reduction condition is 450 ° C, 0.2 MPa (absolute pressure), and the reduction time is 4 hours; after the reduction activation The catalyst precursor B and 300mL of sorbitol solution with a mass concentration of 10% were added to the autoclave, sealed and replac...

Embodiment 2

[0030] Weigh 1.84g of ammonium molybdate and 1.98g of nickel nitrate and dissolve them in an appropriate amount of deionized water to obtain solution A; use an equal volume impregnation method to load 20g of hydrogen ZSM-5 (silicon-aluminum ratio 50, pore volume 0.23ml / g, The specific surface area is 426m 2 / g, strip shape, equivalent diameter 1.5mm) carrier, aged at room temperature for 6h, dried at 110°C for 10h, and calcined at 600°C for 4h to obtain catalyst precursor B, in which Mo accounted for 5% of the weight of the carrier by element, and Ni by element Accounting for 2% of the weight of the carrier; catalyst precursor B is activated in a mixed atmosphere containing hydrogen, the volume content of hydrogen in the mixed gas is 90%, the reduction condition is 400 ° C, 0.2 MPa (absolute pressure), and the reduction time is 8 hours; after the reduction and activation The catalyst precursor B and 300mL of sorbitol solution with a mass concentration of 10% were added to the ...

Embodiment 3

[0032] Weigh 1.84g of ammonium molybdate and 1.98g of nickel nitrate and dissolve them in an appropriate amount of deionized water to obtain solution A; use equal volume impregnation method to load 20g of silicon oxide (pore volume is 1.06ml / g, specific surface area is 387m 2 / g, spherical, equivalent diameter 0.5mm) carrier, aging at room temperature for 8h, drying at 120°C for 6h, and calcining at 600°C for 4h to obtain catalyst precursor B, in which Mo accounts for 5% of the weight of the support as an element, and Ni accounts for The weight of the carrier is 2%; the catalyst precursor B is activated in a mixed atmosphere containing hydrogen, the volume content of hydrogen in the mixed gas is 10%, the reduction condition is 500°C, 0.2MPa (absolute pressure), and the reduction time is 6h; the activated Catalyst precursor B and 300mL sorbitol solution with a mass concentration of 10% were added to the autoclave, sealed and replaced with hydrogen twice, then adjusted the hydrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com