Modified redispersible emulsion powder

A redispersed latex powder and modification technology, applied in the field of additives in the construction field, can solve the problems of low water resistance strength, influence of water resistance bonding performance, etc., and achieve the effect of good water resistance strength, good bonding strength, and increased water resistance strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Formula (weight ratio) of modified redispersible latex powder:

[0019] EVA latex powder 50%

[0020] Tributyl citrate 20%

[0021] Silane coupling agent 0.5%

[0022] Titanate coupling agent 1.0%

[0023] Diatomaceous earth (720 mesh) 28%

[0024] Sodium hexametaphosphate 0.5%

[0025] 2. Preparation

[0026] (1) According to the above formula, pour the silane coupling agent and titanate coupling agent into the tributyl citrate solution, stir at 100 rpm for 5 minutes, then add sodium hexametaphosphate into the above solution, Continue to stir for 5 minutes;

[0027] (2) Add EVA latex powder to the mixture in step (1), and stir at 650 rpm for 10 minutes;

[0028] (3) Add diatomaceous earth into a horizontal mixer, stir slowly at 45 rpm, and use high-pressure spray equipment (pressure 0.3MPa) to evenly spray the mixture in step (2) into the mixer, and stir for 15 minutes to obtain Modified redispersible latex powder.

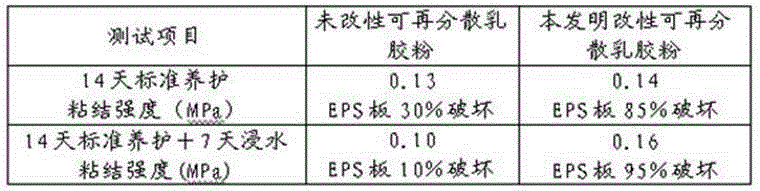

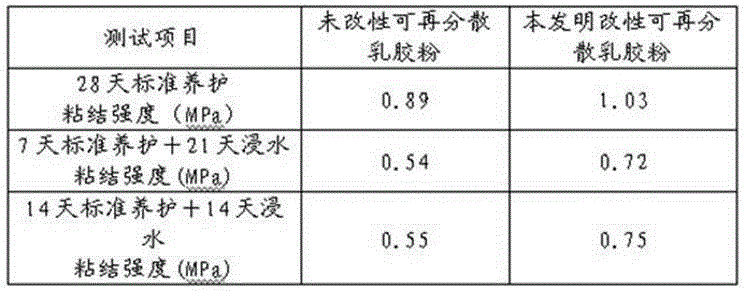

[0029] 3. Application and performance te...

Embodiment 2

[0041] 1. Formula (weight ratio) of modified redispersible latex powder:

[0042] Acrylic powder 40%

[0043] Epoxidized soybean oil 30%

[0044] Silane coupling agent 0.6%

[0045] Titanate coupling agent 1.2%

[0046] Fumed silica (220 mesh) 12.6%

[0047] Diatomaceous earth (750 mesh) 15%

[0048] Polyacrylic acid sodium salt 0.6%

[0049] 2. Preparation

[0050] (1) According to the above formula, pour the silane coupling agent and titanate coupling agent into the epoxy soybean oil solution, stir at 200 rpm for 5 minutes, and then add glyceryl tristearate into the above solution , continue to stir for 5 minutes;

[0051] (2) Add acrylic rubber powder to the mixture in step (1), and stir for 10 minutes at 850 rpm;

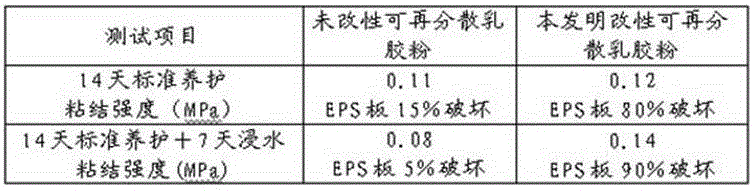

[0052] (3) Add fumed silica and metakaolin to a horizontal mixer, stir slowly at 60 rpm, and use high-pressure spray equipment (pressure 0.4MPa) to evenly spray the mixture in step (2) into the mixer, Stir for 15 minutes to obtain modified redispersible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com