Degradation-controllable magnesium phosphate cement and preparation method and application thereof

A technology of magnesium phosphate bone cement and potassium dihydrogen phosphate, which is applied in medical science, prostheses, tissue regeneration, etc., can solve the problem of difficulty in matching the metabolic rate with the growth rate of new bone, unsatisfactory speed and controllable degradation, and water resistance. Insufficient performance and other problems, to achieve good application prospects, controllable degradation rate, high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

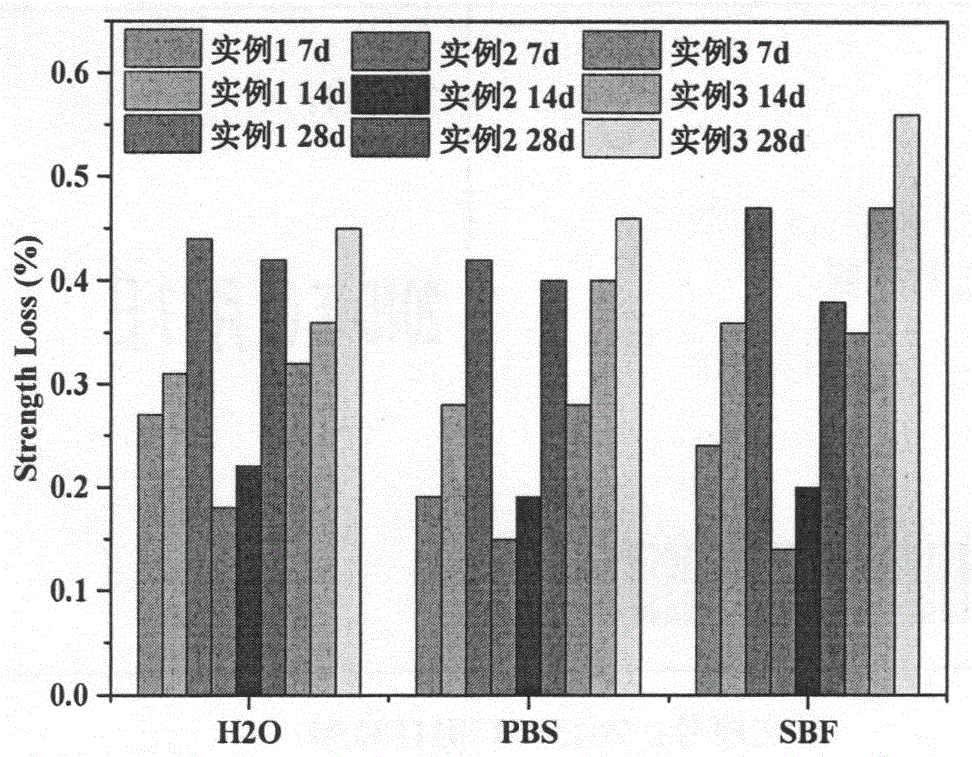

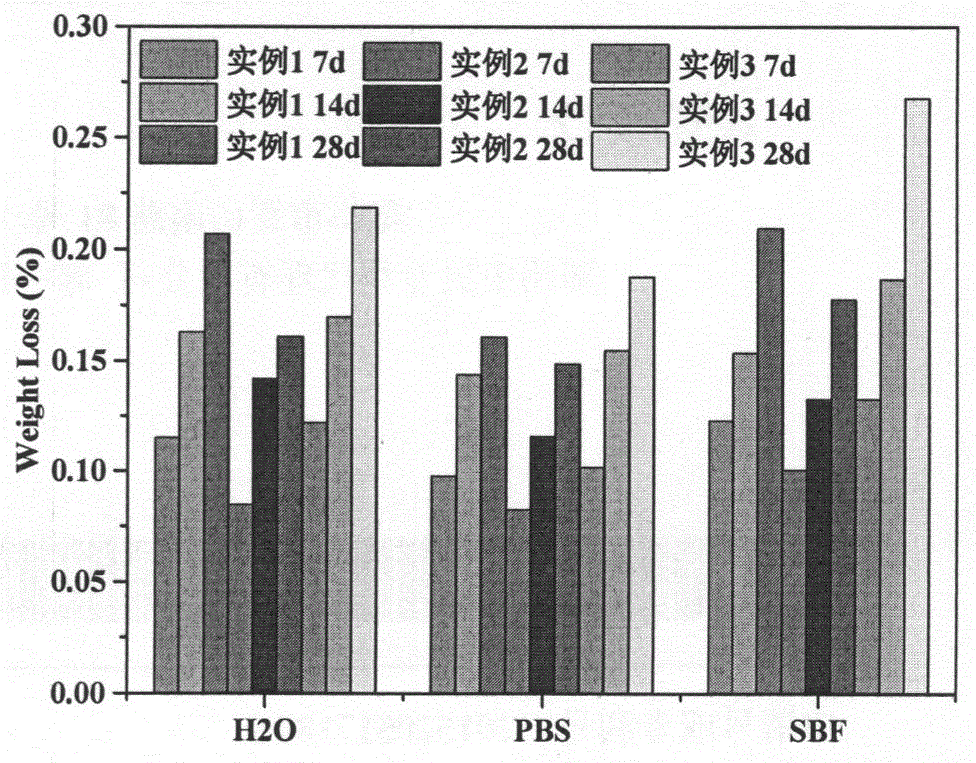

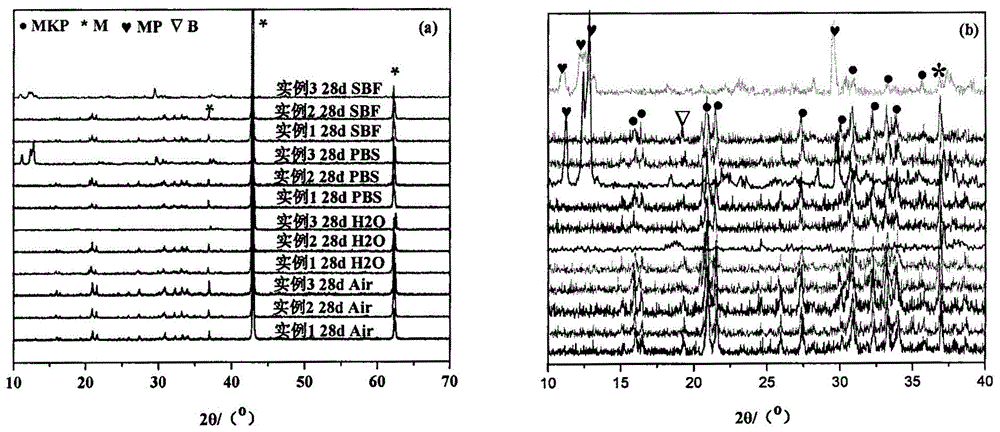

Embodiment 1

[0036] a. Put the analytically pure magnesium hydroxide at 1500°C, heat it for 8 hours, cool it naturally in the furnace, grind it, and pass it through a 200-mesh sieve to obtain the required magnesium oxide powder;

[0037] b. Weigh raw materials by mass percentage: magnesia powder 65%, potassium dihydrogen phosphate 15%, borax 7%, deionized water 13%;

[0038] c, the potassium dihydrogen phosphate weighed in step b, borax and deionized water are fully mixed and stirred;

[0039] d. Add the magnesium oxide powder weighed in step b to the mixed slurry in step c, and quickly and fully mix and stir;

[0040] e. Put the slurry prepared in step d into a mold for molding, and place it in an environment of 20±2°C and a relative humidity of 50±5% for curing to obtain the controllable degradable magnesium phosphate bone cement.

Embodiment 2

[0042] a. Put the analytically pure magnesium hydroxide at 1500°C, heat it for 8 hours, cool it naturally in the furnace, grind it, and pass it through a 200-mesh sieve to obtain the required magnesium oxide powder;

[0043] b. Weigh raw materials according to mass percentage: 65% magnesium oxide powder, 15% potassium dihydrogen phosphate, 7% borax, 12% deionized water, 1% chitosan;

[0044] C, the potassium dihydrogen phosphate weighed in step b, borax, chitosan and deionized water are fully mixed and stirred;

[0045]d. Add the magnesium oxide powder weighed in step b to the mixed slurry in step c, and quickly and fully mix and stir;

[0046] e. Put the slurry prepared in step d into a mold for molding, and place it in an environment of 20±2°C and a relative humidity of 50±5% for curing to obtain the controllable degradable magnesium phosphate bone cement.

Embodiment 3

[0048] a. Put the analytically pure magnesium hydroxide at 1500°C, heat it for 8 hours, cool it naturally in the furnace, grind it, and pass it through a 200-mesh sieve to obtain the required magnesium oxide powder;

[0049] b. Raw materials were weighed according to mass percentage: magnesia powder 65%, potassium dihydrogen phosphate 15%, borax 7%, deionized water 11%, chitosan 1%, hydroxypropyl methylcellulose 1%;

[0050] c, the potassium dihydrogen phosphate weighed in step b, borax, chitosan, hydroxypropyl methylcellulose and deionized water are fully mixed and stirred;

[0051] d. Add the magnesium oxide powder weighed in step b to the mixed slurry in step c, and quickly and fully mix and stir;

[0052] e. Put the slurry prepared in step d into a mold for molding, and place it in an environment of 20±2°C and a relative humidity of 50±5% for curing to obtain the controllable degradable magnesium phosphate bone cement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com