Preparation method of reduction-state ionic salt of perylene bisimide and derivative thereof

A perylene imide and derivative technology, applied in the field of organic matter and its synthesis, can solve the problems of high cost, harsh requirements, unsuitable for industrialization, etc., and achieve the effect of cheap price, high reaction yield, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

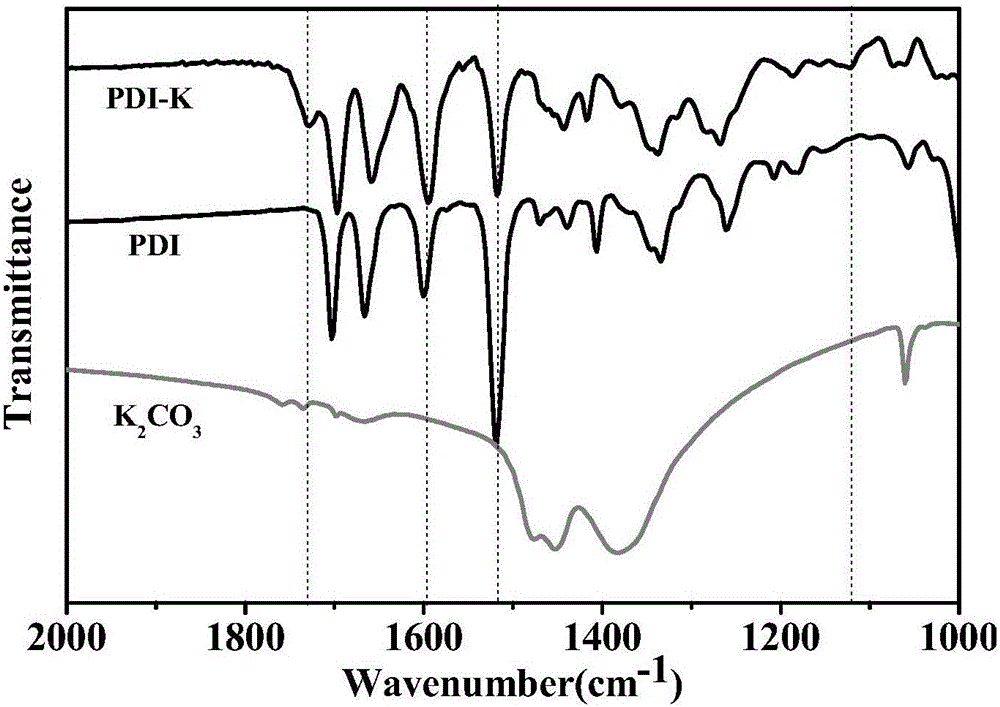

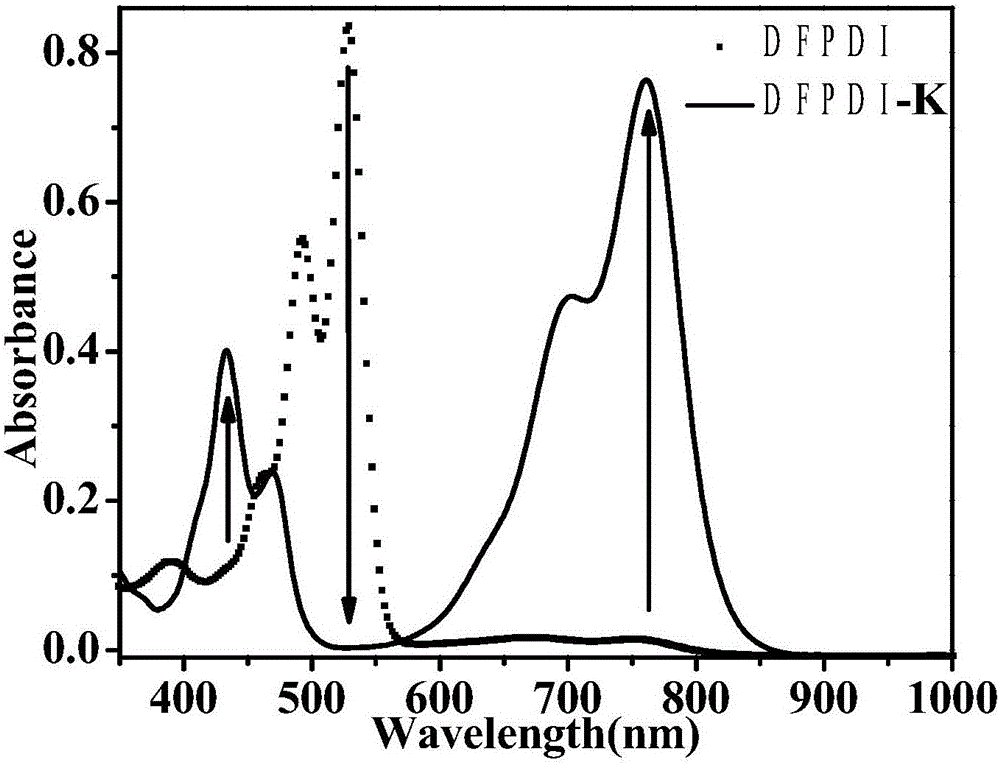

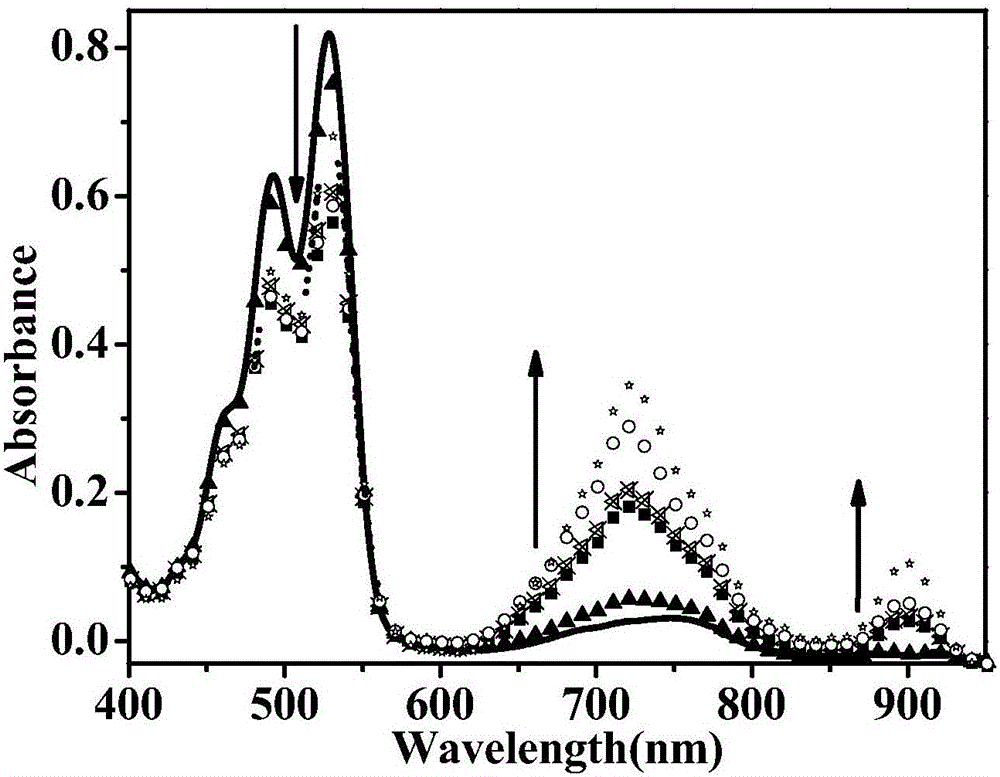

Method used

Image

Examples

Embodiment 1

[0048] Add 2.14 g of 3,4,9,10-perylenetetracarboxylic dianhydride (PTDA) (M=392) into 18 mL of concentrated (98%) H 2 SO 4 (M=98, 1.836g / mL) in a three-necked flask, oscillated by 35Hz ultrasonic waves for 10min, then placed it on a heat-collecting constant temperature magnetic stirrer and added a condensing device, stirred at room temperature for 6h, and then adjusted the temperature to 80 ℃, reflux reaction, adding 0.053gI 2 (M=127) was used as a catalyst and about 0.577mL (3.12g / mL) of liquid bromine (M=160) was slowly added dropwise into it using a constant pressure dropping funnel. After reacting for 24 hours, dilute the reaction solution with concentrated sulfuric acid to 60% with distilled water, then suction filter to obtain a filter cake, and dry the filter cake in a vacuum oven at 90°C for 24 hours. The filter cake mainly contains the aforementioned three compounds a, b, and c, where a:b:c=7:2:1.

[0049] In a 100ml three-necked reaction flask, add respectively 0....

Embodiment 2

[0054] Add 2.09 g of 3,4,9,10-perylenetetracarboxylic dianhydride (PTDA) (M=392) into 18 mL of concentrated (98%) H 2 SO 4 (M=98, 1.836g / mL) in a three-necked flask, oscillated by 35Hz ultrasonic waves for 10min, then placed it on a heat-collecting constant temperature magnetic stirrer and added a condensing device, stirred at room temperature for 6h, and then adjusted the temperature to 80 ℃, reflux reaction, adding 0.052gI 2 (M=127) was used as a catalyst, and about 0.58 mL (3.12 g / mL) of liquid bromine (M=160) was slowly added dropwise into it using a constant pressure dropping funnel. After reacting for 24 hours, dilute the reaction solution with concentrated sulfuric acid to 60% with distilled water, then suction filter to obtain a filter cake, and dry the filter cake in a vacuum oven at 90°C for 24 hours. The filter cake mainly contains the aforementioned three compounds a, b, and c, where a:b:c=7:2:1.

[0055] In a 100ml three-necked reaction flask, add respectively ...

Embodiment 3

[0060] Add 1.98 g of 3,4,9,10-perylenetetracarboxylic dianhydride (PTDA) into 18 mL of concentrated (98%) H 2 SO 4 In a three-necked flask, oscillate with 35Hz ultrasonic waves for 10min, then place it on a heat-collecting constant temperature magnetic stirrer and add a condensing device, stir at room temperature for 6h, adjust the temperature to 80°C, reflux reaction, and add 0.052gI 2 As a catalyst, about 0.58 mL of liquid bromine was slowly added dropwise into it with a constant pressure dropping funnel. After reacting for 24 hours, dilute the reaction solution with concentrated sulfuric acid to 60% with distilled water, then suction filter to obtain a filter cake, and dry the filter cake in a vacuum oven at 90°C for 24 hours. The filter cake mainly contains the aforementioned three compounds a, b, and c, where a:b:c=7:2:1.

[0061] In a 100ml three-necked reaction flask, add 0.95g of bromoperylenetetraanhydride prepared by the above steps, 0.52mL of 17.5mol / L catalyst ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com