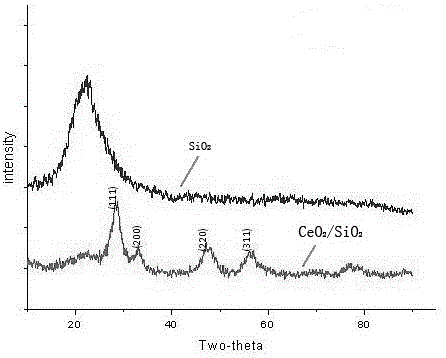

Preparation method of shell-core coated cerium oxide-silicon oxide composite abrasive grains

A composite abrasive grain and silicon oxide technology, which is applied in chemical instruments and methods, other chemical processes, polishing compositions containing abrasives, etc., can solve the problems of unsatisfactory coating effect and low coating degree of cerium oxide, and achieve The effect of ensuring the preparation effect, ensuring the coating effect, and improving the degree of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

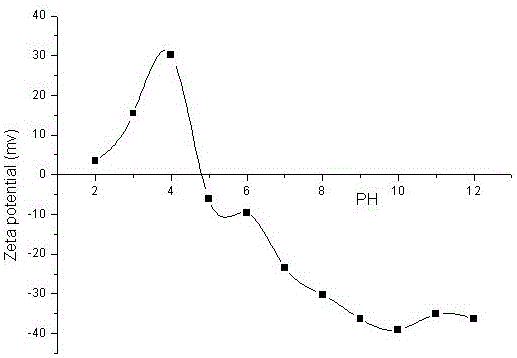

Method used

Image

Examples

Embodiment 1

[0030] Prepare a shell-core coated cerium oxide-silicon oxide composite abrasive grain, which comprises the following steps:

[0031] (1) Preparation of silica suspension: Measure 9ml of commercially available silica polishing solution 6 and 0ml of deionized water at a volume ratio of 1:7, wherein the particle size distribution of commercially available silica polishing solution is 60nm to 100nm, slowly drop 9ml of commercially available silica polishing solution into deionized water at a rate of 12mL / min under the action of magnetic stirring, and magnetically stir for 10min, and the speed of magnetic stirring is controlled at 100r / min to obtain oxidation Silica suspension with silicon mass accounting for 10%; at the same time, by adding dilute sodium hydroxide solution and dilute nitric acid to the silica suspension to control the pH value of the silica suspension within the range of 10 to 10.5;

[0032] (2) Weigh 20.9703g of cerium nitrate hexahydrate with a cerium ion conce...

Embodiment 2

[0038] Prepare a shell-core coated cerium oxide-silicon oxide composite abrasive grain, which comprises the following steps:

[0039] (1) Preparation of silica suspension: Measure 10ml of commercially available silica polishing fluid and 40ml of deionized water at a volume ratio of 1:4, where the particle size distribution of commercially available silica polishing fluid is 60nm ~100nm, slowly drop 10ml of commercially available silica polishing solution into deionized water at a rate of 4.5mL / min under the action of magnetic stirring, and magnetically stir for 15min, the speed of magnetic stirring is controlled at 850r / min, and the oxidation Silica suspension with silicon mass accounting for 6%; at the same time, by adding dilute sodium hydroxide solution and dilute nitric acid to the silica suspension to control the pH value of the silica suspension within the range of 10 to 10.5;

[0040] (2) Weigh 20.9703g of cerium nitrate hexahydrate with a cerium ion concentration of 0....

Embodiment 3

[0046] Prepare a shell-core coated cerium oxide-silicon oxide composite abrasive grain, which comprises the following steps:

[0047] (1) Preparation of silica suspension: Measure 10ml of commercially available silica polishing fluid and 1400ml of deionized water at a volume ratio of 1:14, where the particle size distribution of commercially available silica polishing fluid is 60nm ~100nm, slowly drop 10ml of commercially available silica polishing solution into deionized water at a rate of 18mL / min under the action of magnetic stirring, and magnetic stirring for 20min, the speed of magnetic stirring is controlled at 1600r / min, to obtain silicon dioxide Silica suspension with a mass of 2%; at the same time, by adding dilute sodium hydroxide solution and dilute nitric acid to the silica suspension to control the pH value of the silica suspension within the range of 10 to 10.5;

[0048] (2) Weigh 20.9703g of cerium nitrate hexahydrate with a cerium ion concentration of 0.2mol / L ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com