Low-solid-content reservoir protection workover fluid and preparation method thereof

A technology for reservoir protection and workover fluid, applied in the field of petroleum exploration, can solve problems such as the reduction of daily oil production of self-blowing wells, rapid coning of bottom-hole water, low solid phase reservoirs, etc., and achieves good reservoir protection performance, The preparation process is simple and feasible, and the composition of raw materials is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

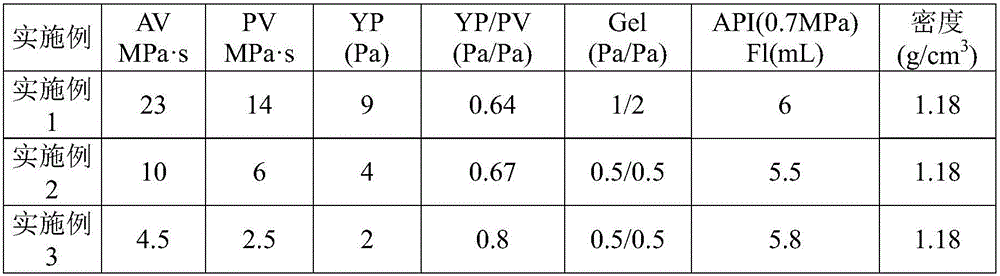

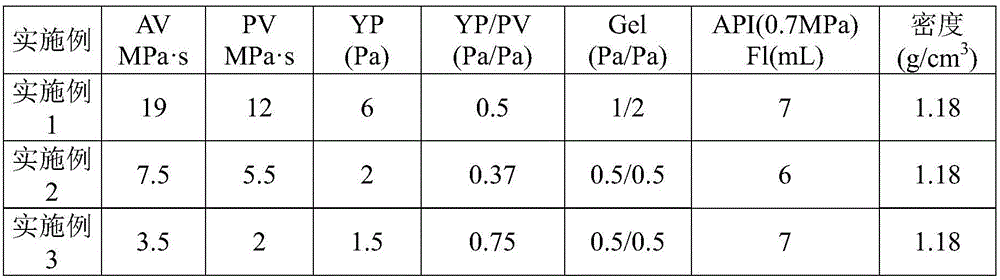

Examples

Embodiment 1

[0029] This embodiment provides a low-solid reservoir protection workover fluid. The raw material composition of the low-solid reservoir protection workover fluid includes pregelatinized starch and saturated sodium chloride anti-salt and anti-corrosion brine, pregelatinized starch The ratio of the weight to the volume of saturated sodium chloride anti-salt anti-corrosion brine is 100:300.

[0030] The above-mentioned low-solid reservoir protection workover fluid is prepared through the following steps:

[0031] Weigh 100 parts by weight of water, put it into a 400mL goblet, then add 0.4 parts by weight of caustic soda to it while stirring at 4000r / min at room temperature, and stir for 5min after the addition;

[0032] Add 10 parts by weight of sodium carboxymethyl starch to the goblet at a speed of 4000r / min, stir for 20 minutes, and wait for the solution to become white and viscous to obtain pregelatinized starch;

[0033] Take 300 parts by weight of water, put it in a 400mL...

Embodiment 2

[0040] This embodiment provides a low-solid reservoir protection workover fluid, which is prepared through the following steps:

[0041] Take 100 parts by weight of water, put it into a 400mL goblet, add 1 part of caustic soda to it while stirring at 4000r / min at room temperature, and stir for 5 minutes after the addition;

[0042] Add 10 parts by weight of hydroxypropyl starch to the goblet at a speed of 4000r / min, stir for 20 minutes after the addition, and wait for the solution to become white and viscous to obtain pregelatinized starch;

[0043] Take 300 parts by weight of water, put it in a 400mL goblet, and add 96 parts by weight of sodium chloride at 4000r / min until it is completely dissolved.

[0044] Add 6 parts by weight of 800-mesh calcium carbonate at a rotating speed of 4000r / min, and stir for 5 minutes after the addition is completed until the mixture is evenly dispersed;

[0045] Add 3 parts by weight of formaldehyde at a speed of 4000 rpm, and stir for 5 minut...

Embodiment 3

[0050] This embodiment provides a low-solid reservoir protection workover fluid, which is prepared through the following steps:

[0051] Take 100 parts by weight of water, put it into a 400mL goblet, add 1 part by weight of caustic soda to it while stirring at room temperature at 4000r / min, and stir for 5 minutes after the addition;

[0052] Add 10 parts by weight of potato starch at a rotating speed of 4000r / min, stir for 20 minutes after the addition is complete, and wait for the solution to become white and viscous to obtain pregelatinized starch;

[0053] Take 300 parts by weight of water, put it in a 400mL goblet, add 96 parts by weight of sodium chloride at 4000r / min until completely dissolved;

[0054] Add 6 parts by weight of 1200-mesh calcium carbonate at a rotating speed of 4000r / min, and stir for 5 minutes after the addition is complete until the mixture is evenly dispersed;

[0055] Add 3 parts by weight of dodecyl dimethyl benzyl ammonium chloride at a rotating s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com