Urban household garbage thermal cracking treatment device and method for conducting urban household garbage thermal cracking with same

A technology of municipal solid waste and treatment device, which is applied in the field of harmless treatment of municipal solid waste, and can solve the problems of low temperature rise rate, unsatisfactory treatment method and low efficiency in the pyrolysis reactor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

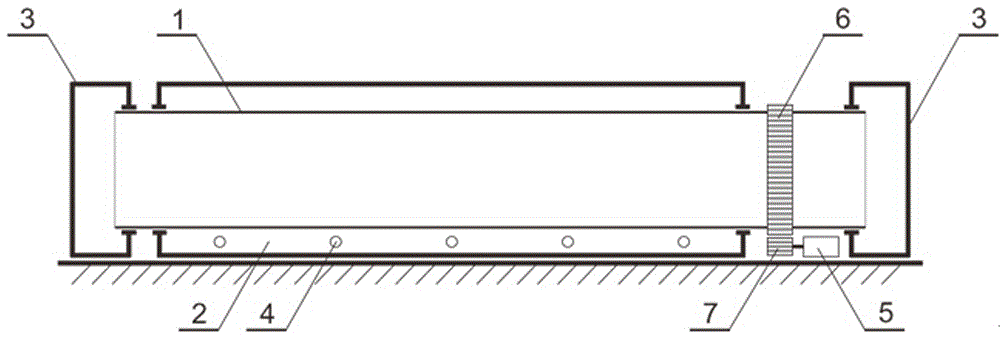

[0008] Embodiment 1: refer to figure 1In this embodiment, the municipal solid waste transported from the garbage dump is pulverized by a pulverizer and then enters the feed bin, and then enters the thermal cracking reactor from the still head supporting the thermal cracking reactor through the garbage dehydrator. The motor is connected with the driven gear through the driving gear to drive the thermal cracking reactor to rotate. The thermal cracking reactor is placed in the combustion chamber, the outer diameter of the thermal cracking reactor is dynamically fitted and connected to the combustion chamber, and a gas burner is arranged in the combustion chamber. Municipal solid waste is evenly heated and fully cracked in the thermal cracking reactor. The cracked gas enters the quenching, separation and purification device from the reactor head 3, and light bio-oil, heavy Bio-oil and combustible bio-gas. The combustible biogas is used by the gas burner installed in the combusti...

Embodiment 2

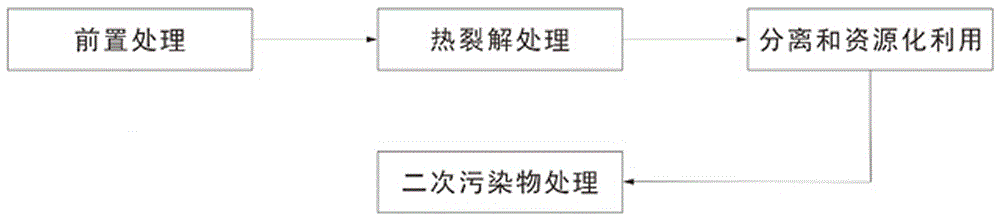

[0009] Embodiment 2: refer to figure 2 ,

[0010] (1) Pre-processing

[0011] The garbage from the garbage dump enters the silo through the shredder, and then is lifted into the dehydrator. The size of the pulverized municipal solid waste is 10-100 mm, preferably 30-50 mm; if the size is too small, it is easy to form a paste, which is not convenient for subsequent transportation, and the size as small as possible is convenient for heat transfer inside the municipal solid waste.

[0012] (2) Thermal cracking treatment

[0013] Use the cracked gas or liquefied petroleum gas stored in the early stage to burn and heat the pyrolysis reactor through the gas burner installed in the combustion chamber, so that the entire pyrolysis reactor is evenly heated at a high temperature, and the municipal solid waste from the dehydrator enters the combustion chamber The middle-rotating thermal cracking reactor is fully heated and cracked to achieve a high-efficiency heat conduction state. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com