LED (light-emitting diode) electronic display screen detergent, and preparation method and cleaning method

An electronic display and cleaning agent technology, applied in detergent compositions, chemical instruments and methods, non-surface active detergent compositions, etc., to achieve non-toxic and harmless human body, strong self-cleaning function and water repellency, environmental safety and environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

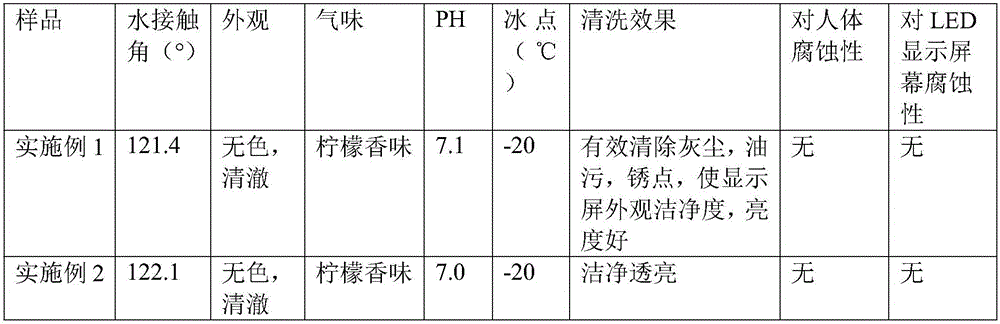

Examples

Embodiment 1

[0032] Prepare LED electronic display screen self-cleaning cleaning agent 1 according to the following method:

[0033] 1) Prepare Enteromorpha extract:

[0034] Step 1. Dry the fresh Enteromorpha, break it into 60-mesh powder, add 10 times the weight of Enteromorpha powder in an aqueous ethanol solution with a mass fraction of 50%, perform ultrasonic extraction at a temperature of 80°C for 4 hours, and then centrifuge and suction filter. Obtain filtrate, centrifugal condition is 3000r / min, centrifugal 10min;

[0035] Step 2. Put the filtrate in a vacuum rotary evaporator, distill under reduced pressure at 45°C to recover ethanol, and when no more ethanol is distilled out, keep the remaining liquid;

[0036] Step 3, fractionating the remaining liquid in step 2, and collecting the effluent at a temperature of 93°C;

[0037] 2) Weigh 3 parts of 2-10nm rutile nano-TiO2 powder purchased from York Company in the United States, 12 parts of Enteromorpha extract, 12 parts of citric ...

Embodiment 2

[0039] Prepare LED electronic display screen self-cleaning cleaning agent 2 according to the following method:

[0040] 1) Prepare Enteromorpha extract:

[0041] Step 1. Dry the fresh Enteromorpha, break it into 100-mesh powder, add 20 times the weight of Enteromorpha powder in an aqueous ethanol solution with a mass fraction of 70%, conduct ultrasonic extraction at a temperature of 80° C. for 5 hours, and then centrifuge and suction filter. Obtain filtrate, centrifugal condition is 4000r / min, centrifugal 5min;

[0042] Step 2. Put the filtrate in a vacuum rotary evaporator, distill and recover ethanol under reduced pressure at 60°C, and keep the remaining liquid when no more ethanol is distilled out;

[0043] Step 3, fractionating the remaining liquid in step 2, and collecting the effluent at a temperature of 90-95°C;

[0044] 2) Weigh 4 parts of 2-10nm rutile nano-TiO2 powder purchased from York Company in the United States, 11 parts of Enteromorpha extract, 14 parts of citr...

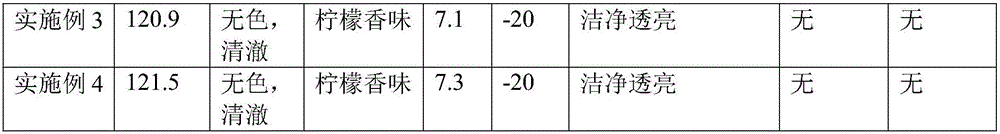

Embodiment 3

[0046] Prepare LED electronic display screen self-cleaning cleaning agent 3 according to the following method:

[0047] 1) Prepare Enteromorpha extract:

[0048] Step 1. Dry the fresh Enteromorpha, break it into 40-mesh powder, add 15 times the weight of Enteromorpha powder in an 80% ethanol aqueous solution, conduct ultrasonic extraction at a temperature of 80° C. for 6 hours, then centrifuge and suction filter. Obtain filtrate, centrifugal condition is 5000r / min, centrifugal 10min;

[0049] Step 2. Put the filtrate in a vacuum rotary evaporator, distill and recover ethanol under reduced pressure at 50°C, and keep the remaining liquid when no more ethanol is distilled out;

[0050] Step 3, fractionating the remaining liquid in step 2, and collecting the effluent at a temperature of 90-94°C;

[0051] 2) Weigh 1 part of 10-20nm rutile nano-TiO2 powder purchased from Japan Catarise Co., Ltd., 16 parts of Enteromorpha extract, 15 parts of citric acid, 3 parts of triglyceride, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com