Multifunctional environment-friendly dyeing deepening agent and preparation method thereof

A darkening agent and multi-functional technology, which can be used in dyeing, textile and paper making, etc., can solve the problems of poor stability and poor compatibility, and achieve the effect of improving the dyeing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

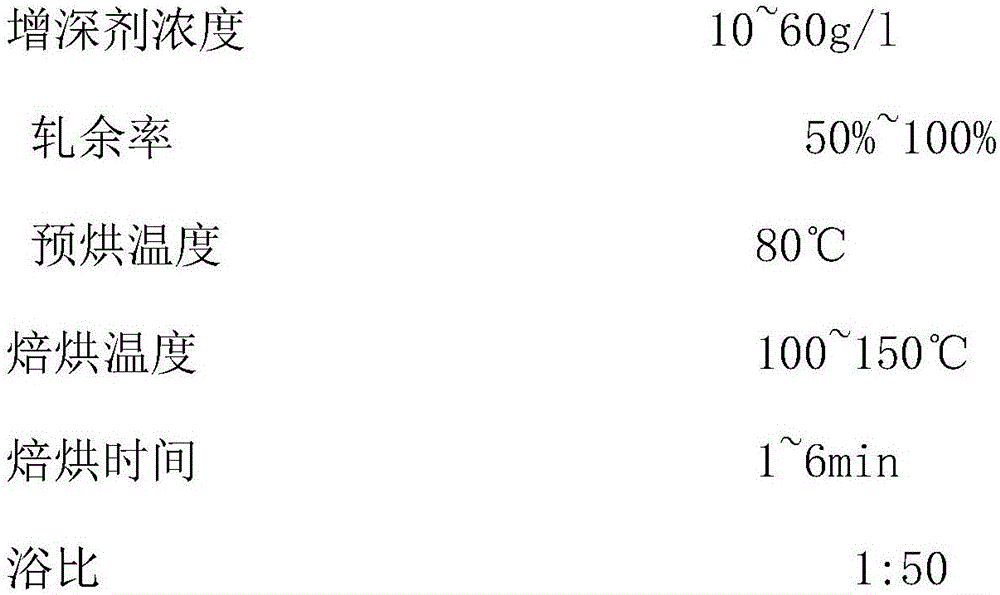

Method used

Image

Examples

Embodiment 1

[0051] A multifunctional environment-friendly dyeing darkening agent, in parts by weight, comprises the following components:

[0052] 2 parts of lignin, 6 parts of chitosan oligosaccharide,

[0053] 3 parts of nano silica sol, 2 parts of transglutaminase,

[0054] 4 parts of sodium secondary alkyl sulfonate, 7 parts of fluorine acrylic emulsion,

[0055] 2 parts of calcium sulfate, 1 part of modified cyclodextrin,

[0056] 1 part of polyoxypropylene polyoxyethylene block copolymer,

[0057] 2 parts of α-carboxyacetic acid,

[0058] Fluoroalkyl polyether modified polysiloxane 1 part,

[0059] 20 parts of deionized water.

[0060] Its preparation method comprises the following steps:

[0061] (1) Mix and stir lignin, chitosan oligosaccharide, fluoroacrylic emulsion, polyoxypropylene polyoxyethylene block copolymer and deionized water evenly, heat up to 50°C, and stir at constant temperature for 1.5h at 5000 rpm , to get mixed emulsion;

[0062] (2) Nano-silica sol, seco...

Embodiment 2

[0065] A multifunctional environment-friendly dyeing darkening agent, in parts by weight, comprises the following components:

[0066] 5 parts of lignin, 10 parts of chitosan oligosaccharide,

[0067] 8 parts of nano silica sol, 6 parts of transglutaminase,

[0068] 8 parts of sodium secondary alkyl sulfonate, 12 parts of fluoroacrylic emulsion,

[0069] 4 parts of calcium sulfate, 3 parts of modified cyclodextrin,

[0070] 1.5 parts of polyoxypropylene polyoxyethylene block copolymer,

[0071] 3 parts of α-carboxyacetic acid,

[0072] Fluoroalkyl polyether modified polysiloxane 3 parts,

[0073] 30 parts of deionized water.

[0074] Its preparation method comprises the following steps:

[0075] (1) Mix and stir lignin, chitosan oligosaccharide, fluoroacrylic emulsion, polyoxypropylene polyoxyethylene block copolymer and deionized water evenly, raise the temperature to 70°C, and stir at a constant temperature for 2 hours at 5000 rpm. Obtain mixed emulsion;

[0076] (2) N...

Embodiment 3

[0079] A multifunctional environment-friendly dyeing darkening agent, in parts by weight, comprises the following components:

[0080] 3.5 parts of lignin, 7 parts of chitosan oligosaccharide,

[0081] 5 parts of nano-silica sol, 4 parts of transglutaminase,

[0082] 4 parts of sodium secondary alkyl sulfonate, 10 parts of fluoroacrylic emulsion,

[0083] 2.2 parts of calcium sulfate, 2 parts of modified cyclodextrin,

[0084] 1 part of polyoxypropylene polyoxyethylene block copolymer,

[0085] 2 parts of α-carboxyacetic acid,

[0086] Fluoroalkyl polyether modified polysiloxane 1.5 parts,

[0087] 30 parts of deionized water.

[0088] Its preparation method comprises the following steps:

[0089] (1) Mix and stir lignin, chitosan oligosaccharide, fluoropropylene emulsion, polyoxypropylene polyoxyethylene block copolymer and deionized water evenly, heat up to 55°C, and stir at constant temperature for 1.6h at 5000 rpm , to get mixed emulsion;

[0090] (2) Nano-silica s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com