Visible-blind ultraviolet detector based on Beta-Ga2O3/SiC heterojunction thin film and fabrication method of visible-blind ultraviolet detector

An ultraviolet detector, -ga2o3 technology, applied in the field of ultraviolet detectors, can solve the problems of weak signal processing ability and sunlight interference, etc., and achieve the effect of sensitive response, stable performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Proceed as follows:

[0028] 1) Pretreatment of n-type 6H-SiC substrate: put n-type 6H-SiC substrate into V(HF):V(H 2 o 2 )=1:5 solution soaked to remove the natural oxide layer, then ultrasonic cleaning with acetone, ethanol and deionized water respectively, and vacuum drying;

[0029] 2) Place the target and substrate: place the Ga 2 o 3 The target is placed on the target stage of the laser molecular beam epitaxy system, and the n-type 6H-SiC substrate processed in step 1) is fixed on the sample holder and put into the vacuum chamber;

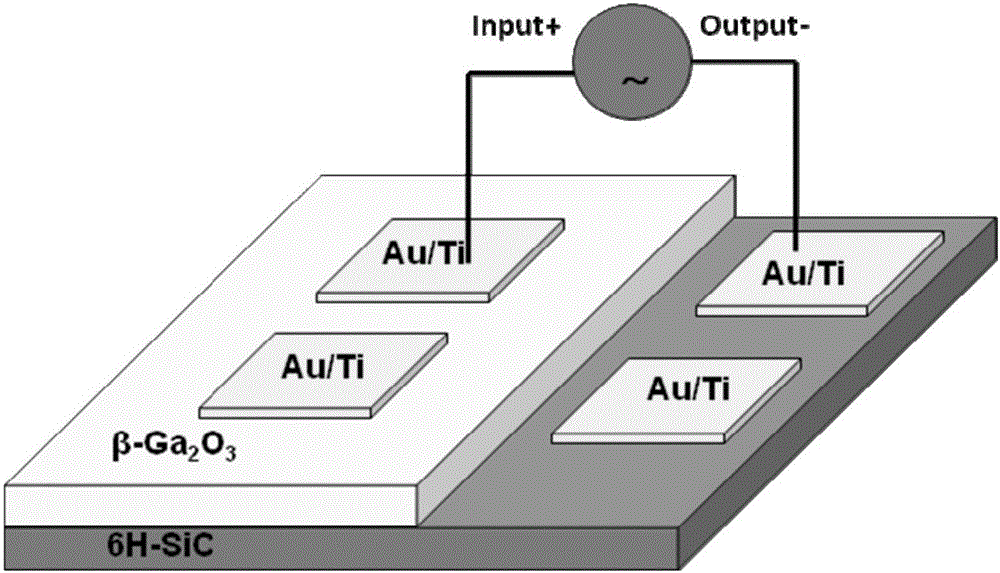

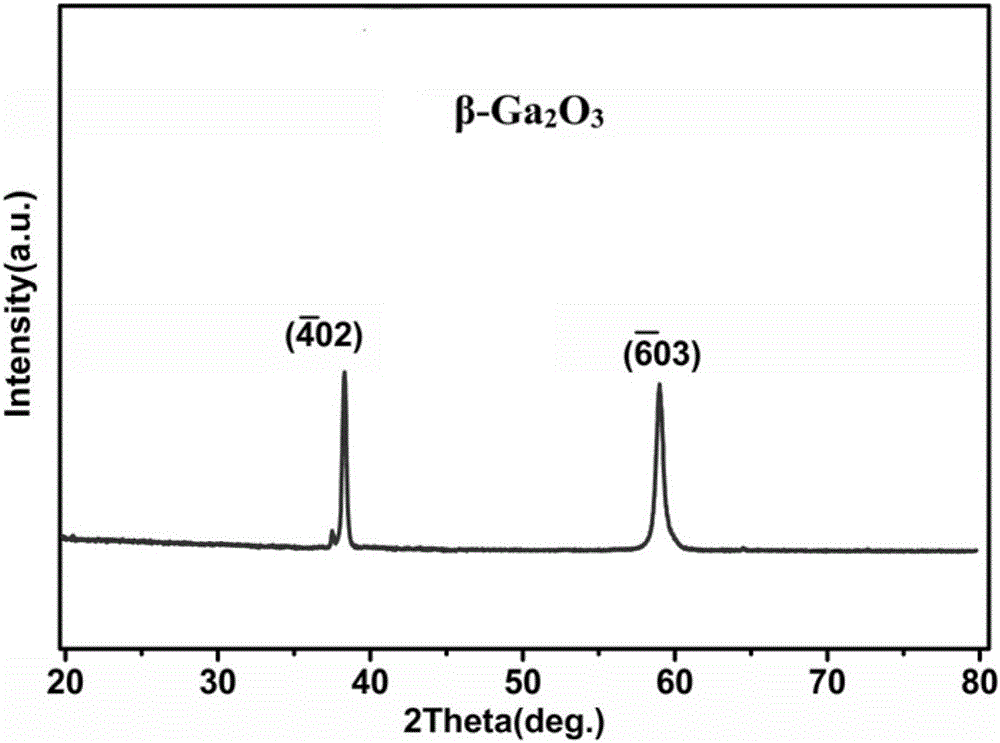

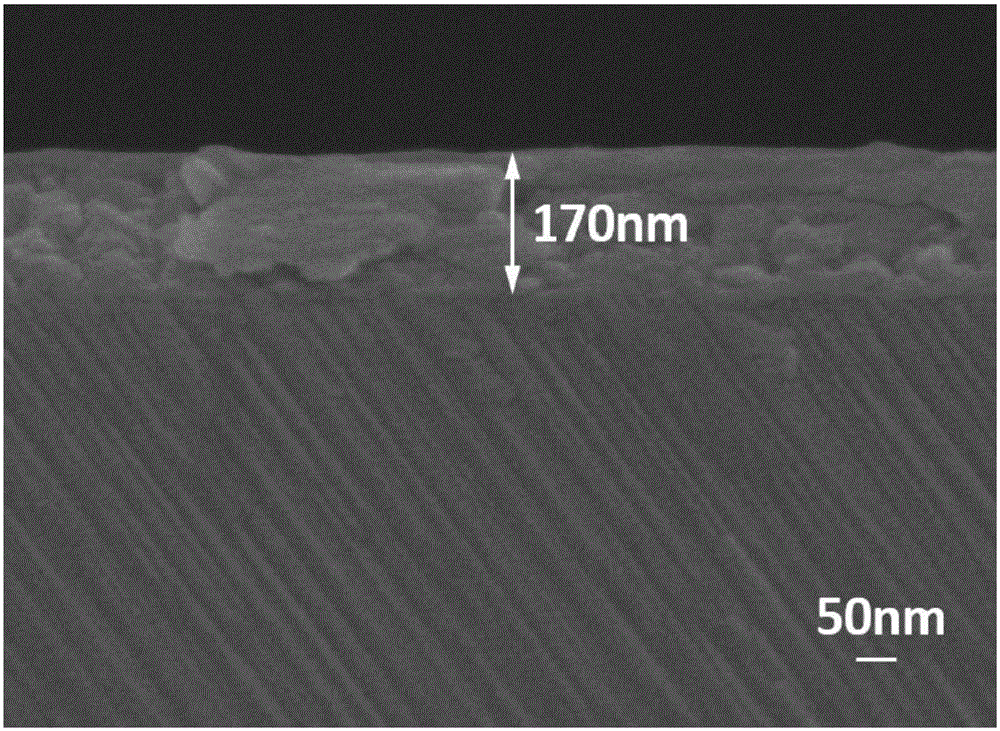

[0030] 3) β-Ga 2 o 3 Thin film deposition process: first vacuumize the chamber, feed oxygen, adjust the pressure in the vacuum chamber, heat the n-type 6H-SiC substrate, and grow β-Ga 2 o 3 film, after the film growth is completed, the resulting β-Ga 2 o 3 The thin film is annealed in situ; among them, Ga 2 o 3 The distance between the target and the n-type 6H-SiC substrate was set at 5 cm, and the chamber pressure after vac...

Embodiment 2

[0035] Steps (1), (2) and (4) are all the same as in Example 1. In step (3), the chamber is first evacuated, oxygen is introduced, the pressure in the vacuum chamber is adjusted, and the n-type 6H-SiC substrate is heated to grow β-Ga 2 o 3 film, after the film growth is completed, the resulting β-Ga 2 o 3 The thin film is annealed in situ; among them, Ga 2 o 3 The distance between the target and the n-type 6H-SiC substrate was set at 5 cm, and the chamber pressure after vacuuming was 1×10 -6 Pa, the chamber pressure is 1×10 after oxygen is introduced -3 Pa, laser energy is 400mJ / cm 2 , the laser pulse frequency is 1Hz, the laser wavelength is 248nm, the heating temperature of n-type 6H-SiC substrate is 750℃, β-Ga 2 o 3 The annealing temperature of the film is 700° C., and the annealing time is 1.5 hours.

[0036] The resulting β-Ga 2 o 3 The chemical composition and structure of the film are similar to Example 1. Based on β-Ga 2 o 3 / SiC thin-film sun-blind ultra...

Embodiment 3

[0038] Steps (1), (2) and (4) are all the same as in Example 1. In step (3), the chamber is first evacuated, oxygen is introduced, the pressure in the vacuum chamber is adjusted, and the n-type 6H-SiC substrate is heated to grow β-Ga 2 o 3 film, after the film growth is completed, the resulting β-Ga 2 o 3 The thin film is annealed in situ; among them, Ga 2 o 3 The distance between the target and the n-type 6H-SiC substrate was set at 5 cm, and the chamber pressure after vacuuming was 1×10 -6 Pa, the chamber pressure is 1×10 after oxygen is introduced -3 Pa, laser energy is 400mJ / cm 2 , the laser pulse frequency is 1Hz, the laser wavelength is 248nm, the heating temperature of n-type 6H-SiC substrate is 750℃, β-Ga 2 o 3 The annealing temperature of the film is 750° C., and the annealing time is 1.5 hours.

[0039] The resulting β-Ga 2 o 3 The chemical composition and structure of the film are similar to Example 1. Based on β-Ga 2 o 3 / SiC thin-film sun-blind ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com