Multiphase mixing catalytic oxidation VOCs treatment method and treatment system

A catalytic oxidation and multi-phase mixing technology, which is applied in the field of air pollution control, can solve the problems of large investment, heavy weight, and need for preheating of complete sets of equipment, so as to improve oxidation efficiency and service life, facilitate combination configuration and expansion, and react The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

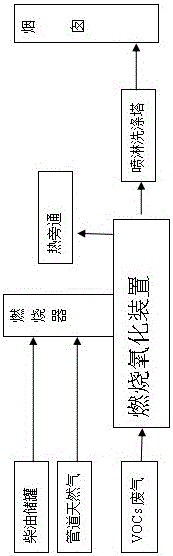

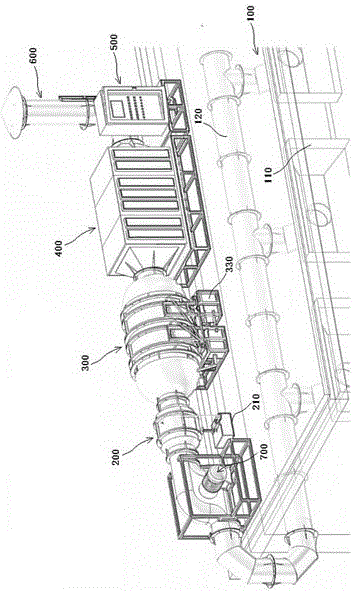

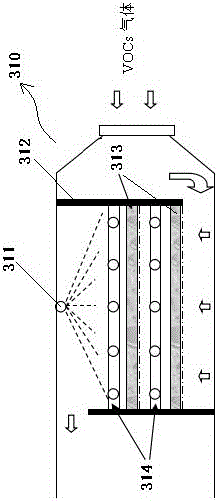

[0032] Such as figure 2 As shown, the preferred scheme of the heterogeneous mixed catalytic oxidation VOCs treatment system implementing the preferred method of the present invention includes sequentially connected gas collection devices, air induction devices, pretreatment devices, multiphase mixed catalytic oxidation devices and photocatalytic oxidation devices.

[0033] The gas collection device includes a gas collection hood and a gas delivery pipe. The gas delivery pipeline is connected by a flange. Under the power of the air induction device, the VOCs gas is transported to the pretreatment device. The air induction device specifically adopts a turbine FRP anti-corrosion outdoor energy-saving fan.

[0034] In the pretreatment device, the VOCs gas with dust particles, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com