Method for preparing polyatomic self-doped graphene using natural porous and layered vegetables

A layered structure, polyatomic technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of graphene's small specific surface area, instability, toxicity, etc., to achieve good electrical conductivity and improve electrical conductivity. , Increase the effect of edge defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Wash the fresh eggplant with water, peel it, cut it into pieces, put it in the prepared 0.5M KOH solution, and let it soak for 24 hours;

[0037] 2) The material obtained in step 1) is taken out and placed in a freeze-drying oven at -50°C and 10Pa for 36 hours to obtain a dry porous fluffy block structure;

[0038] 3) Weigh 10 g of the material obtained in step 2), place it in a tube furnace, raise the temperature at 5°C per minute to 800°C for 1 hour under an argon protective atmosphere, and then cool down;

[0039] 4) After the product obtained in step 3) was manually ground, it was placed in 250ml 0.5M H 2 SO 4 The solution was acid-washed in a constant temperature water bath at 80°C for 9 hours, then suction-filtered, and washed with water until neutral;

[0040] 5) Dry the sample obtained in step 4) in a vacuum oven at 80° C. to obtain graphene.

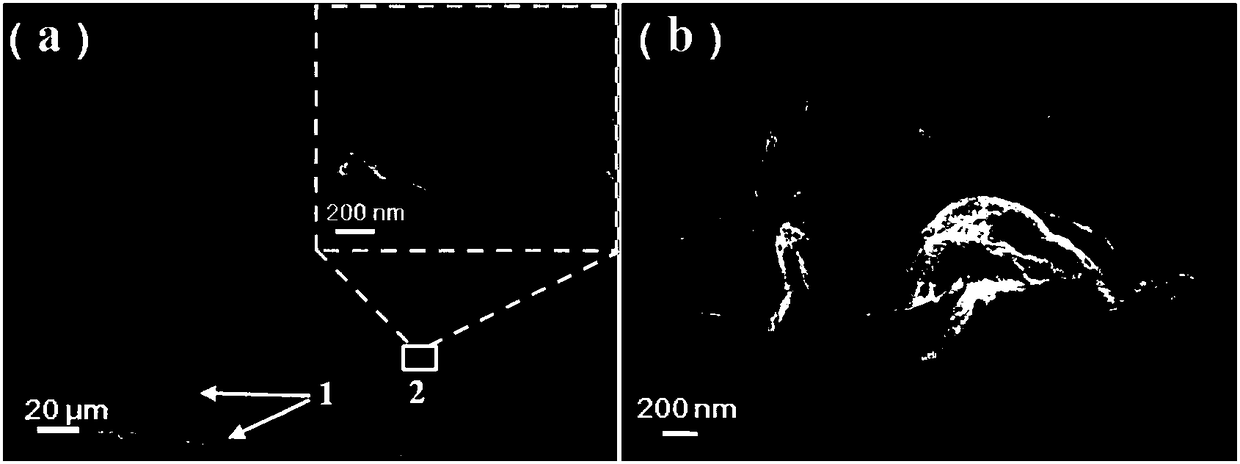

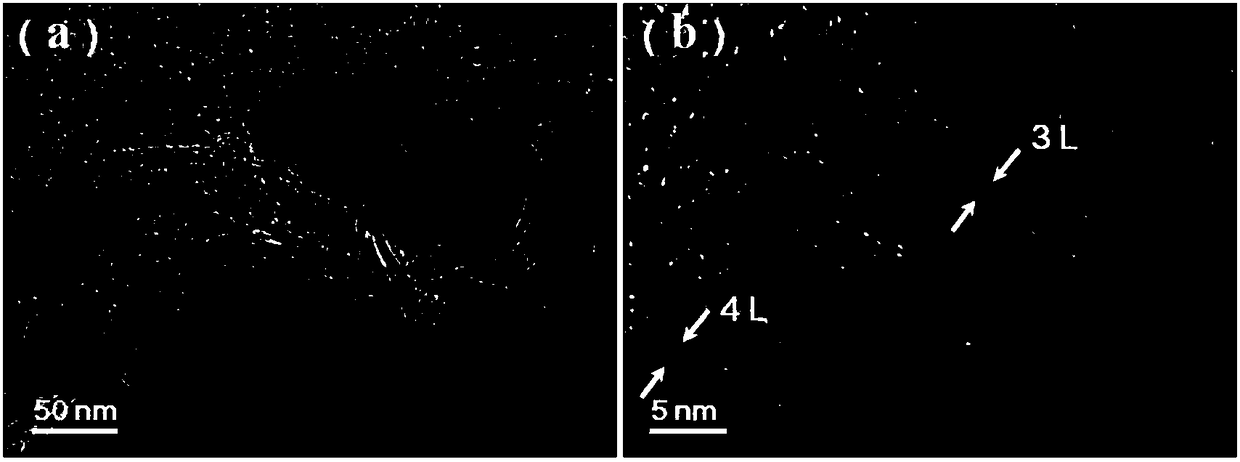

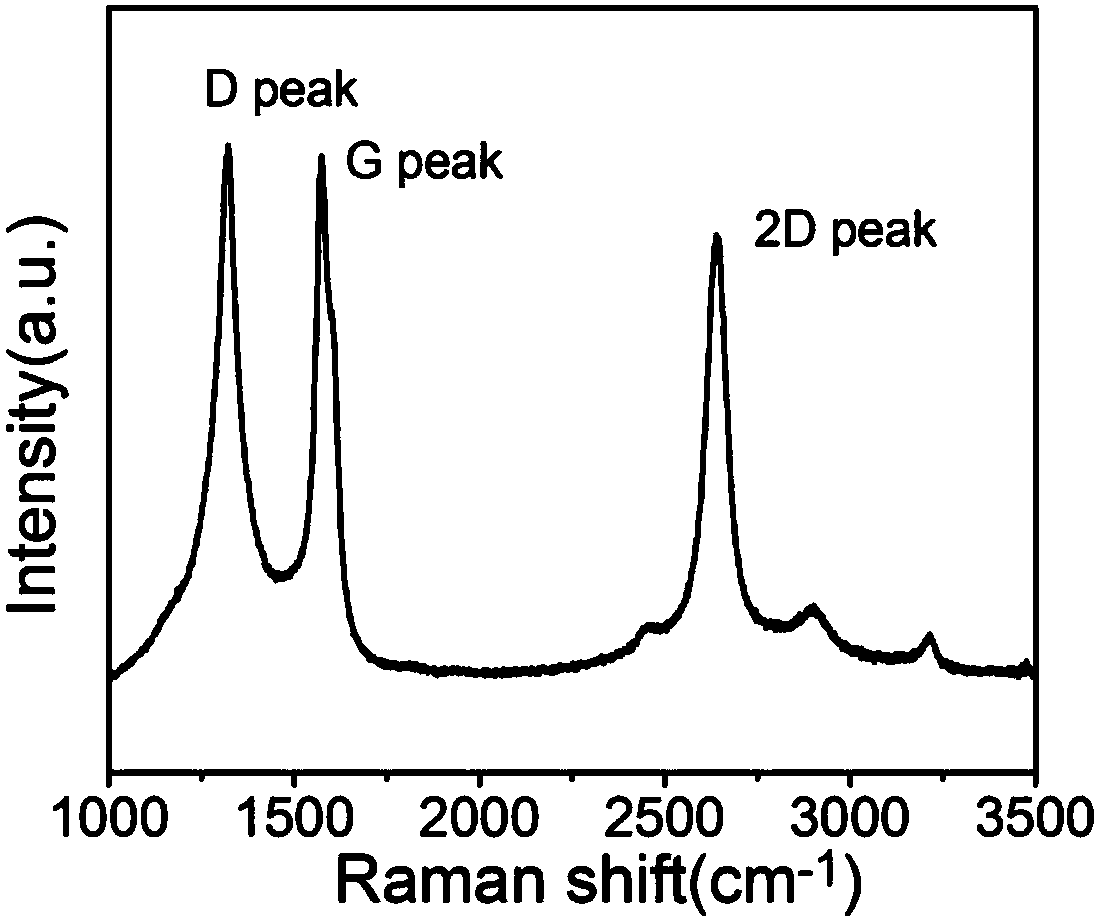

[0041] The specific surface area of the prepared graphene can reach 1102m 2 g -1 , wherein the content of N ele...

Embodiment 2

[0050] 1) Wash the fresh cucumber with water, peel it, cut it into pieces, place it in the prepared 0.3M KOH solution, and allow it to soak for 48 hours;

[0051] 2) The material obtained in step 1) is taken out and placed in a freeze-drying oven at -20°C and 15Pa for 40 hours to obtain a dry porous fluffy block structure;

[0052] 3) Place the material obtained in step 2) in a tube furnace, raise the temperature from 7°C per minute to 700°C for 1.5 hours under a nitrogen protective atmosphere, and then cool down;

[0053] 4) After the product obtained in step 3) was manually ground, it was placed in 250 ml of 0.3M HCl solution and acid-washed at 80°C for 9 hours in a constant temperature water bath, then filtered with suction, and washed with water until neutral;

[0054] 5) Dry the sample obtained in step 4) in a vacuum oven at 60° C. to obtain graphene.

[0055] The specific surface area of the prepared graphene can reach 1221m 2 g -1 , wherein the content of N element...

Embodiment 3

[0057] 1) Wash the fresh lettuce with water, peel it, cut it into pieces, place it in the prepared 0.6M KOH solution, and allow it to soak for 36 hours;

[0058] 2) The material obtained in step 1) is taken out and placed in a freeze-drying oven at -10°C and 10Pa for 65 hours to obtain a dry porous fluffy block structure;

[0059] 3) Weigh 10 g of the material obtained in step 2), place it in a tube furnace, raise the temperature from 6°C per minute to 700°C for 0.5h under an argon protective atmosphere, and then cool down;

[0060] 4) After the product obtained in step 3) was manually ground, it was placed in 200ml of 0.3M HCl solution and acid-washed at 70°C for 6 hours in a constant-temperature water bath, then suction-filtered, and washed with water until neutral;

[0061] 5) Dry the sample obtained in step 4) in a vacuum drying oven at 70° C. to obtain graphene.

[0062] The specific surface area of the prepared graphene can reach 1233m 2 g -1 , wherein the content o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com