A kind of equipment and method for removing sodium sulfate in brine

A technology of sodium sulfate and brine, applied in the field of sodium sulfate equipment, can solve the problems of inconvenient transportation and storage, high energy consumption and input equipment costs, and achieve the effects of preventing scaling or crystallization, reducing energy consumption and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

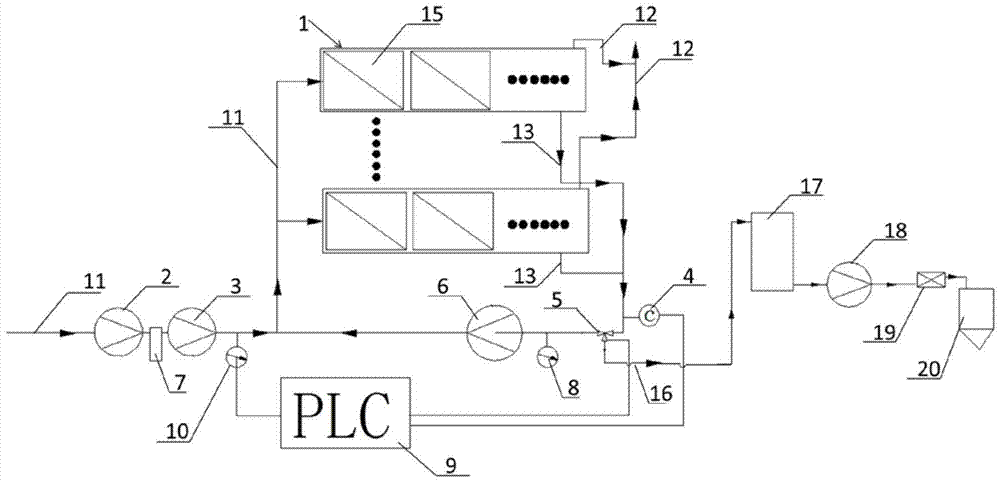

Image

Examples

example 1

[0055] The concentration of sodium chloride in brine is 200g / l, the concentration of sodium sulfate contained in brine is 65g / l, the pH value is 6.5, the lattice distortion agent is 10ppm, and the maximum operating pressure is 68bar. The concentration of sodium sulfate in the dope is 165g / l. After the dope enters the buffer tank 17 to remove the lattice distortion agent, the dope is heated to 57°C through the heat exchanger 19, and then enters the room temperature crystallizer 20 for normal temperature crystallization and precipitation. After the anhydrous sodium sulfate is dried by a centrifuge, it is directly packed into bags.

example 2

[0057] The concentration of sodium chloride in the brine is 230g / l, the concentration of sodium sulfate contained in the brine is 45g / l, the pH value is 7, the lattice distortion agent is 11ppm, and the maximum operating pressure is 60bar. The concentration of sodium sulfate in the dope is 135g / l. After the dope enters the buffer tank 17 to remove the lattice distortion agent, the dope is heated to 58°C through the heat exchanger 19, and then enters the room temperature crystallizer 20 for normal temperature crystallization and precipitation. After the anhydrous sodium sulfate is dried by a centrifuge, it is directly packed into bags.

example 3

[0059] The concentration of sodium chloride in brine is 200g / l, the concentration of sodium sulfate contained in brine is 65g / l, the pH value is 5.5, the lattice distortion agent is 10ppm, and the maximum operating pressure is 50bar. The concentration of sodium sulfate in the dope is 100g / l. After the dope enters the buffer tank 17 to remove the lattice distortion agent, the dope is heated to 57° C. through the heat exchanger 19, and then enters the room temperature crystallizer 20 without crystallization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com