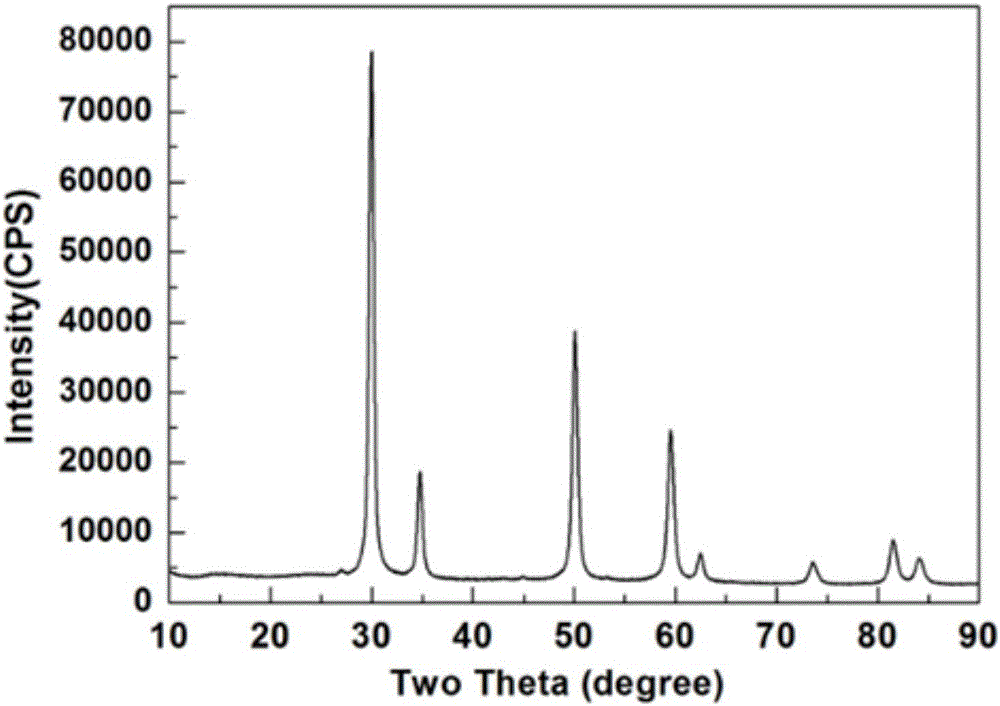

Novel method of preparing nano zirconium oxide powder for dentistry

A nano-zirconia and powder technology, applied in the field of nano-materials, can solve the problems of large powder particle size, high cost and poor dispersibility, and achieve the effects of uniform powder particle size, fast reaction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

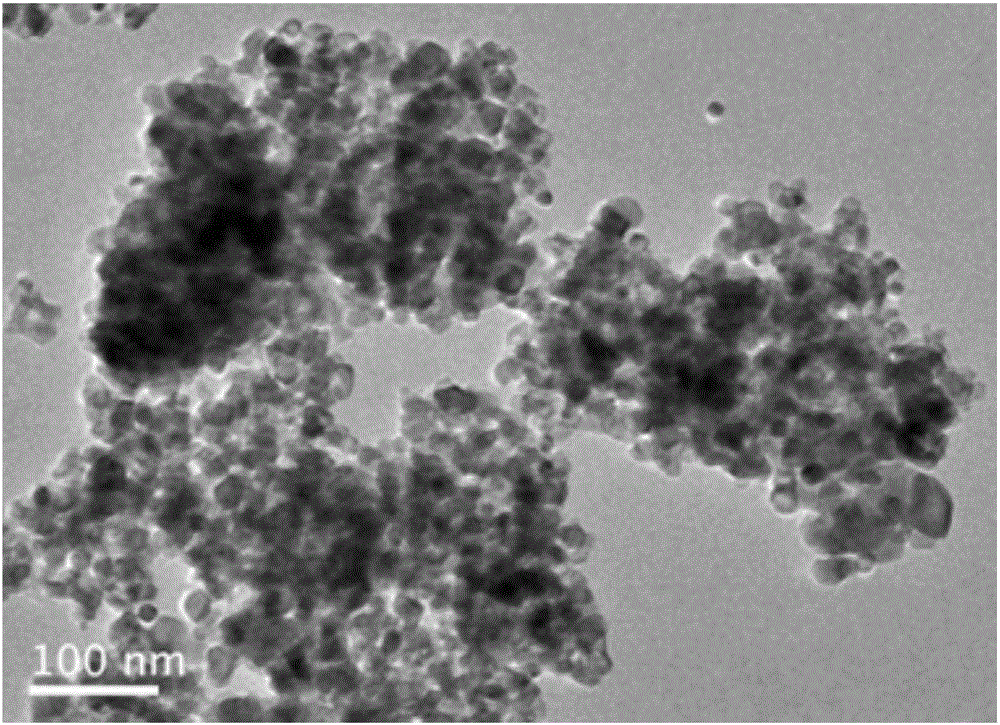

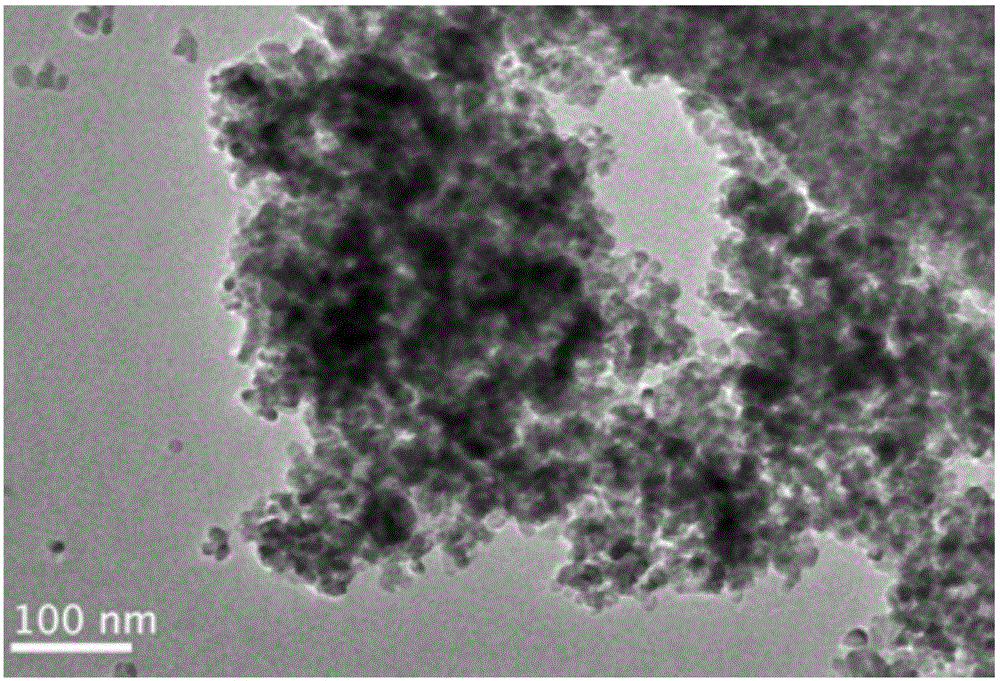

Embodiment 1

[0032] ZrOCl 2 ·8H 2 O and YCl 3 ·6H 2 After O is dissolved in deionized water respectively, stir and mix; the concentration of the mixed solution of zirconium salt and yttrium salt is 0.8mol / L, and the total amount of the mixed solution is 1mol. ZrOCl 2 ·8H 2 O is 0.97mol, YCl 3 ·6H 2 O is 0.03mol; Add the dispersant dehydrated alcohol to the mixed solution and the ammonia solution respectively, stir and constant volume; the amount of dehydrated alcohol accounts for 20% of the volume of the zirconium salt, yttrium salt mixed solution and the volume of the ammonia solution respectively; the amount of the ammonia solution On the basis of satisfying the amount required for the chemical reaction with zirconium salt and yttrium salt, the excess amount is 10%, so as to adjust the pH value of the precipitation reaction at about 8.7. Inject the mixed solution of zirconium salt, yttrium salt and ammonia solution into the reactor at room temperature at a flow rate of 60L / h, and a...

Embodiment 2

[0034] ZrOCl 2 ·8H 2 O and YCl 3 ·6H 2 After O is dissolved in deionized water respectively, stir and mix; the concentration of the mixed solution of zirconium salt and yttrium salt is 0.8mol / L, and the total amount of the mixed solution is 1mol. ZrOCl 2 ·8H 2 O is 0.95mol, YCl 3 ·6H 2 O is 0.05mol; Add the dispersant dehydrated alcohol to the mixed solution and the ammonia solution respectively, stir and constant volume; On the basis of satisfying the amount required for the chemical reaction with zirconium salt and yttrium salt, the excess amount is 10%, so as to adjust the pH value of the precipitation reaction at about 8.7. Inject the mixed solution of zirconium salt, yttrium salt and ammonia solution into the reactor at room temperature at a flow rate of 60L / h, and at the same time vigorously stir to form a white precipitate at a stirring speed of 800rpm; without aging, quickly use a large amount of deionized Dilute with water to obtain a white slurry; filter the w...

Embodiment 3

[0036] ZrOCl 2 ·8H 2 O and YCl 3 ·6H 2 After O is dissolved in deionized water respectively, stir and mix; the concentration of the mixed solution of zirconium salt and yttrium salt is 0.8mol / L, and the total amount of the mixed solution is 1mol. ZrOCl 2 ·8H 2 O is 0.92mol, YCl 3 ·6H 2 O is 0.08mol; Add the dispersant absolute ethanol to the mixed solution and the ammonia solution respectively, stir and constant volume; the amount of absolute ethanol accounts for 20% of the volume of the zirconium salt, the yttrium salt mixed solution and the ammonia solution volume; On the basis of satisfying the amount required for the chemical reaction with zirconium salt and yttrium salt, the excess amount is 10%, so as to adjust the pH value of the precipitation reaction at about 8.7. Inject the mixed solution of zirconium salt, yttrium salt and ammonia solution into the reactor at room temperature at a flow rate of 60L / h, and at the same time vigorously stir to form a white precipi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com