Method for rapidly preparing monodisperse polyvinyl alcohol microspheres at normal temperature

A technology of polyvinyl alcohol microspheres and polyvinyl alcohol, applied in chemical instruments and methods, gel preparation, chemical/physical/physicochemical processes, etc., can solve the problem of inability to achieve fast and convenient preparation of PVA microspheres and long curing time , high curing temperature and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] This embodiment provides a method for rapidly preparing monodisperse polyvinyl alcohol microspheres at room temperature, and the structure of the microchannel reactor it adopts is as follows: Figure 4 shown.

[0072] The microchannel reactor includes a droplet generation zone, a fluid convection mixing zone in the droplet, and a droplet pre-crosslinking solidification zone, wherein:

[0073] The channel in the droplet generation area has a width of 100 microns and a height of 150 microns, which is a flow-focused micro channel, including two dispersed phase channels and two continuous phase channels;

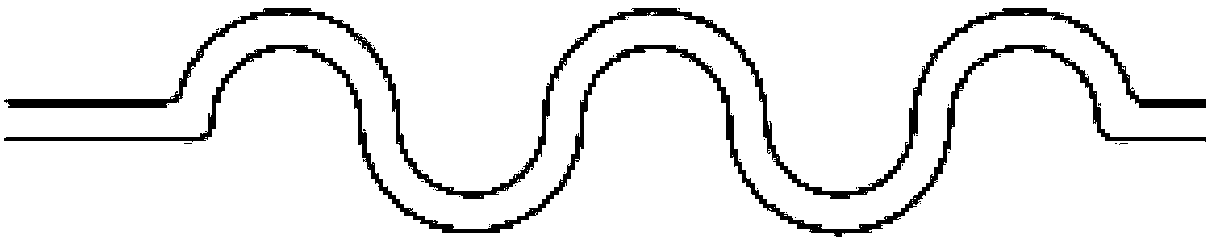

[0074] The length L of the channel of the fluid convective mixing zone in the droplet is 6654 microns and the width W 1 is 200 microns and a height of 150 microns,

[0075] The length L of the channel in the droplet pre-crosslinking curing zone 3 4000 microns, width W 2 is 1000 microns and a height of 150 microns;

[0076] The channels in the fluid convective mixing ...

Embodiment 2

[0092] This embodiment provides a method for rapidly preparing monodisperse polyvinyl alcohol microspheres at room temperature, and the structure of the microchannel reactor it adopts is as follows: figure 2 shown.

[0093] The microchannel reactor includes a droplet generation zone, a fluid convection mixing zone in the droplet, a droplet pre-crosslinking solidification zone, and a collection bottle (not shown), wherein:

[0094] The width of the channel in the droplet generation area is 300 microns, and the height is 300 microns. It is a T-shaped micro channel, including two dispersed phase channels and two continuous phase channels;

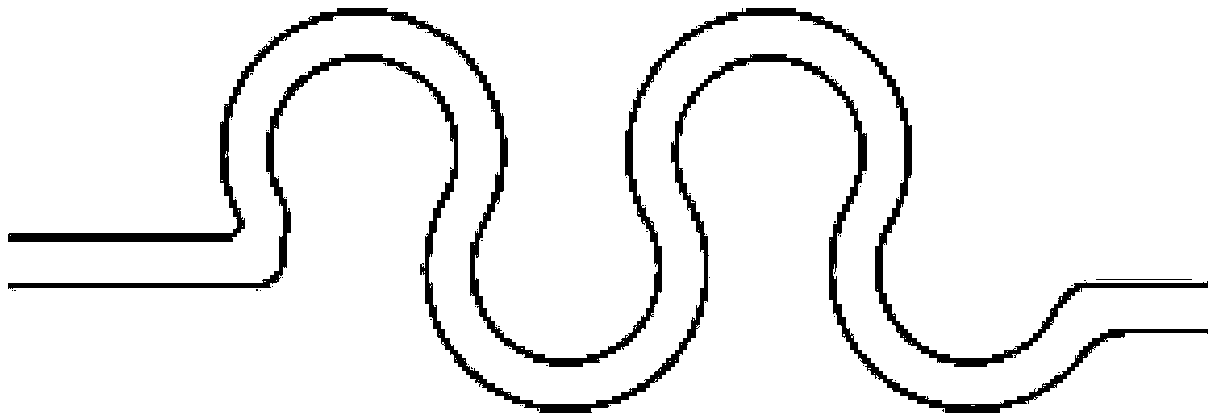

[0095] The length of the channel of the fluid convective mixing zone in the droplet is 13000 microns, the width is 700 microns, and the height is 300 microns,

[0096] The length of the channel in the droplet pre-crosslinking curing zone is 6000 microns, the width is 5600 microns, and the height is 300 microns;

[0097] The Z-shaped curved ...

Embodiment 3

[0106] The microchannel reactor provided in Example 2 was used to prepare monodisperse polyvinyl alcohol microspheres according to the steps in Example 2, the difference being that the continuous phase solution was prepared as follows: 5.0 grams of Span 80 was added to 100 mL of mineral oil and mixed evenly. as a continuous phase solution. The polyvinyl alcohol microspheres obtained in the experiment are in the shape of hazelnuts, and the particle diameter is 160±10 microns. Its scanning electron microscope picture is shown in Figure 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com