A kind of starch/phenolic resin composite adhesive and preparation method thereof

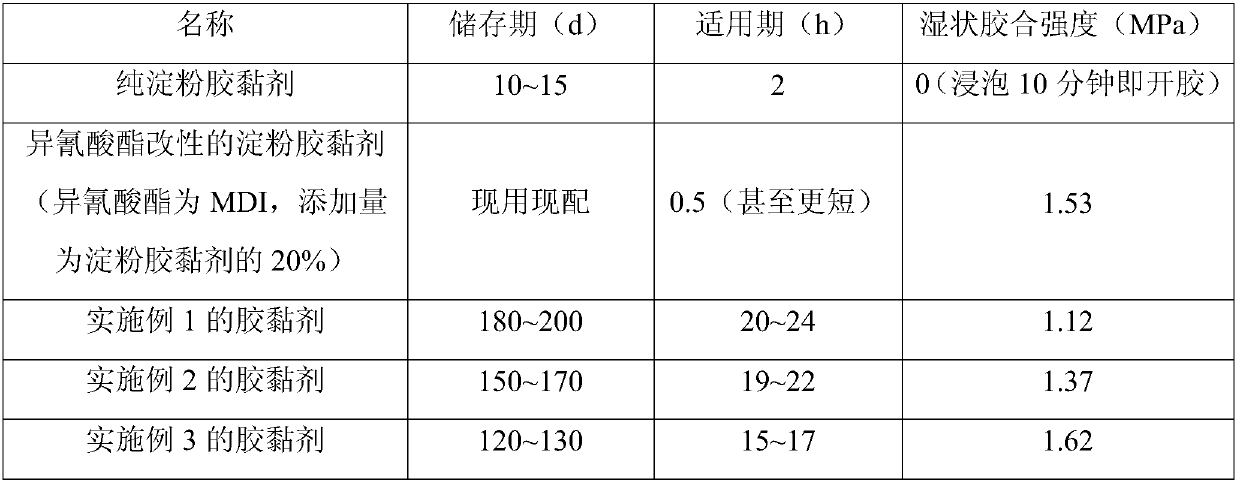

A composite adhesive and phenolic resin technology, applied in the field of wood adhesives, can solve the problems of short pot life, low bonding strength and interface incompatibility of modified adhesives, so as to improve storage stability and adhesive bonding. The effect of strength, good storage stability, simplified production and use process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of starch / phenolic resin composite adhesive of the present invention is made up of the raw material of following components: 162g starch, 243g water, 216g concentration are 15% polyvinyl alcohol 1788 aqueous solution, 0.22g ammonium persulfate, 1.62g sodium hypochlorite, 47.1g phenol, 40.6g mass concentration are 37% formaldehyde solution and 2g sodium hydroxide.

[0027] The preparation method of the starch / phenolic resin composite adhesive of the present embodiment may further comprise the steps:

[0028] (1) Add 47.1g of fused phenol, 28.4g of 37% formaldehyde solution and 2g of sodium hydroxide into the reactor, and heat up to 70°C at a constant rate; then add 12.2g of formaldehyde solution, react for 6 hours, cool down and discharge, Obtain phenolic resin;

[0029] (2) Add 216g of polyvinyl alcohol solution with a mass fraction of 15% into the reactor, then add 0.22g of ammonium persulfate and react at 40°C for 30min; then add 162g of starch, 243g of water ...

Embodiment 2

[0031] A kind of starch / phenolic resin composite adhesive of the present invention is made up of the raw material of following components: 162g starch, 378g water, 324g mass concentration are 10% polyvinyl alcohol 1799 aqueous solution, 0.52g ammonium persulfate, 3.24g sodium hypochlorite , 65.9g phenol, 85.22g mass concentration are 37% formaldehyde solution and 10 parts of sodium hydroxide.

[0032] The preparation method of the starch / phenolic resin composite adhesive of the present embodiment may further comprise the steps:

[0033] (1) Add 65.9g of molten phenol, 59.65g of formaldehyde solution with a mass concentration of 37% and 10g of sodium hydroxide into the reaction kettle, and raise the temperature to 75°C at a constant speed; then add 25.57g of formaldehyde solution, react for 7.2h, cool down and discharge , to obtain phenolic resin;

[0034] (2) Add 324g of polyvinyl alcohol solution with a mass fraction of 10% into the reactor, then add 0.52g of ammonium persul...

Embodiment 3

[0036] A kind of starch / phenolic resin composite adhesive of the present invention is made up of the raw material of following components: 162g starch, 648g water, 378g concentration are 5% polyvinyl alcohol 1788 aqueous solution, 0.76g ammonium persulfate, 4.86g sodium hypochlorite, 94.1g phenol, 162.3g mass concentration are 37% formaldehyde solution and 16g sodium hydroxide.

[0037] The preparation method of the starch / phenolic resin composite adhesive of the present embodiment may further comprise the steps:

[0038] (1) Add 94.1g of fused phenol, 113.61g of 37% formaldehyde solution and 16g of sodium hydroxide into the reactor, and heat up to 80°C at a constant rate; then add 48.69g of formaldehyde solution, react for 8 hours, cool down and discharge, Obtain phenolic resin;

[0039] (2) Add 378g of polyvinyl alcohol solution with a mass fraction of 5% into the reactor, then add 0.76g of ammonium persulfate and react at 60°C for 60min; then add 162g of starch, 648g of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com