Nuclear safety shell surface defect automatic detection method and system

A nuclear containment and automatic detection technology, applied in image analysis, image enhancement, instruments, etc., can solve the problems of affecting the efficiency of processing, defect extraction interference, large amount of image information on the outer surface of the containment, etc., to ensure production safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

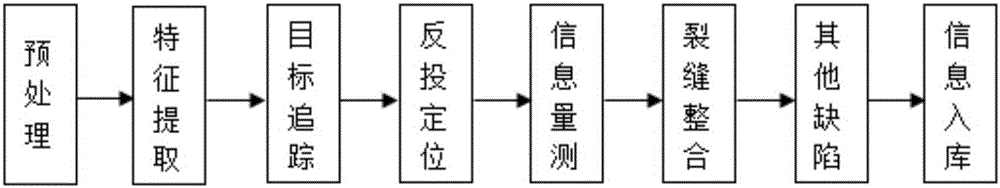

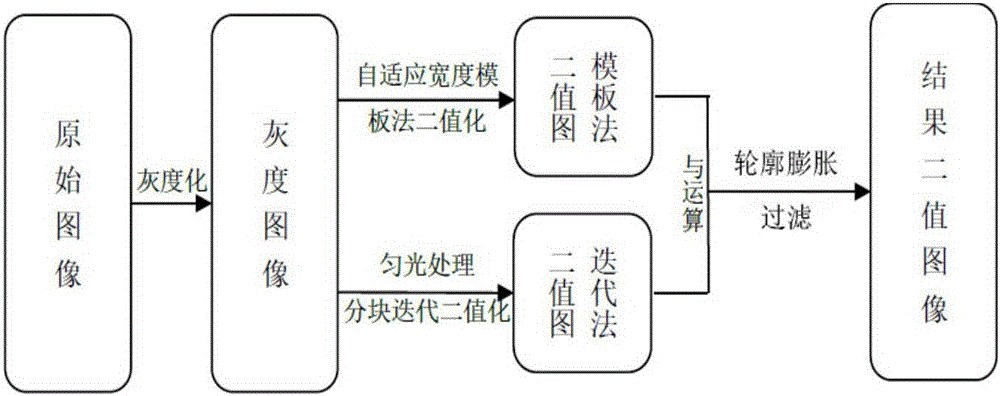

[0068] According to the collected images, the invention proposes a method for detecting surface defects of nuclear containment based on digital image processing. This method fully considers the characteristics of the nuclear containment surface image, can effectively detect defects according to actual engineering needs, breaks the limitations of traditional manual identification, and the results are more accurate and more objective.

[0069] The images used in the embodiment of the present invention are all taken by Nikon D800, the effective pixels are 7360×4912, the lens is Nikon AF Nikkor 28mmF / 1.8G, the object distance is 91cm, and the pixel resolution of the captured images is 0.13mm. The software operating system is Windows 8 Chinese Professional Edition (64-bit), the programming language is C++, the compiler is MicrosoftVisualStudio2012 (64-bit), the image processing library is OPENCV2.4.9, the database is MicrosoftSQLServer2012 (64-bit), and the image workstation is DELL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com