Trench type fast recovery diode and its preparation method

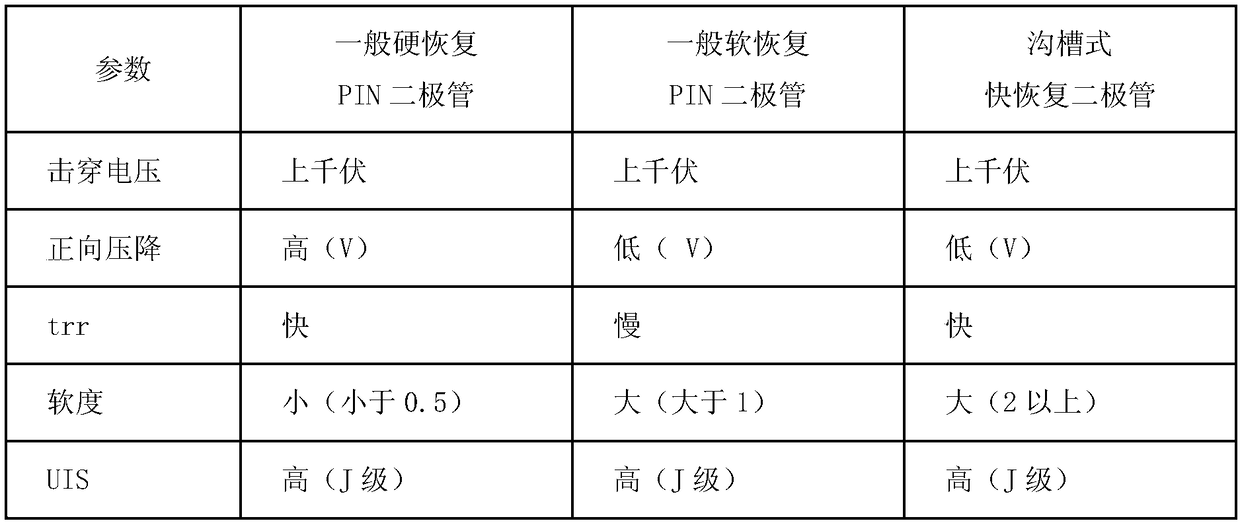

A recovery diode, trench technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as adverse effects, and achieve the effect of reducing injection, voltage drop, and reverse recovery time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

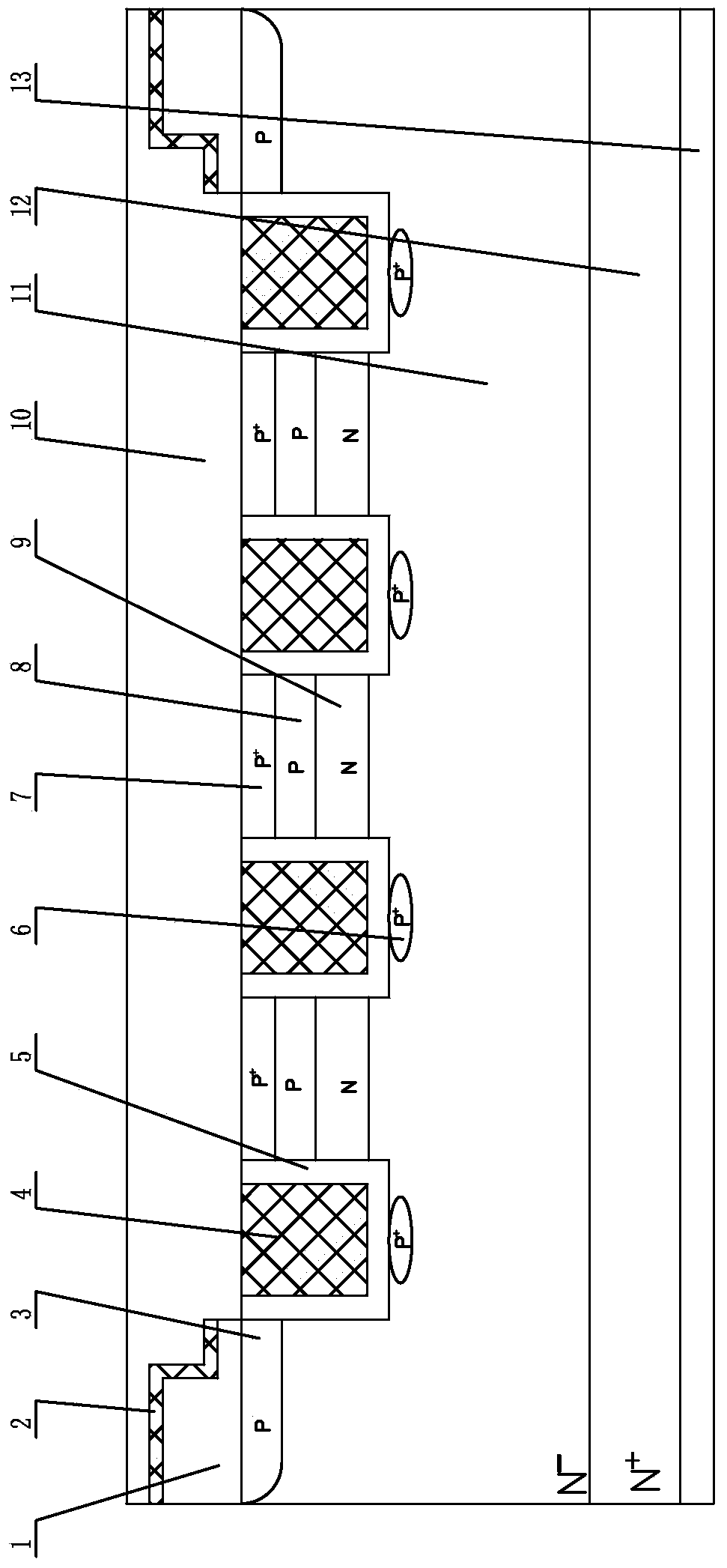

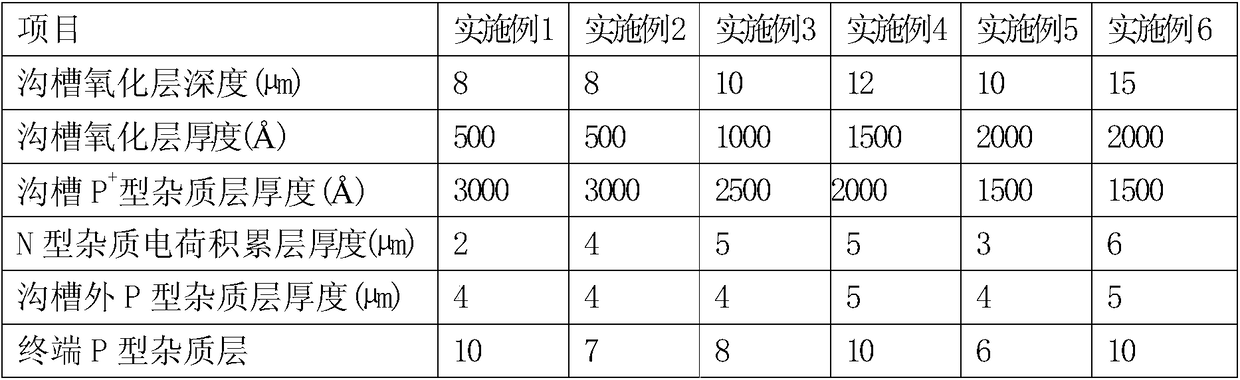

[0037] See figure 1 As shown, the trench type fast recovery diode of the present invention includes successively connected metal cathode layers 13, N + type substrate layer 12 and N - type epitaxial layer 11, N - There is a field oxide layer 1 on the upper part of the epitaxial layer 11, and more than three trench oxide layers 5 are arranged at intervals in the active region window of the field oxide layer 1, and an implantation region outside the trench is located between two trench oxide layers 5, and the trench The oxide layer 5 has a concave cavity, and the trench oxide layer 5 of the present invention has a depth of 8-15um and a wall thickness of The cavity of the trench oxide layer 5 is filled with trench polysilicon 4, and the bottom of each trench oxide layer 5 is in contact with the trench P + Type impurity layer 6 is connected, the trench P + The thickness of the type impurity layer 6 can be controlled in and trench P + type impurity layer 6 embedded in the N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com