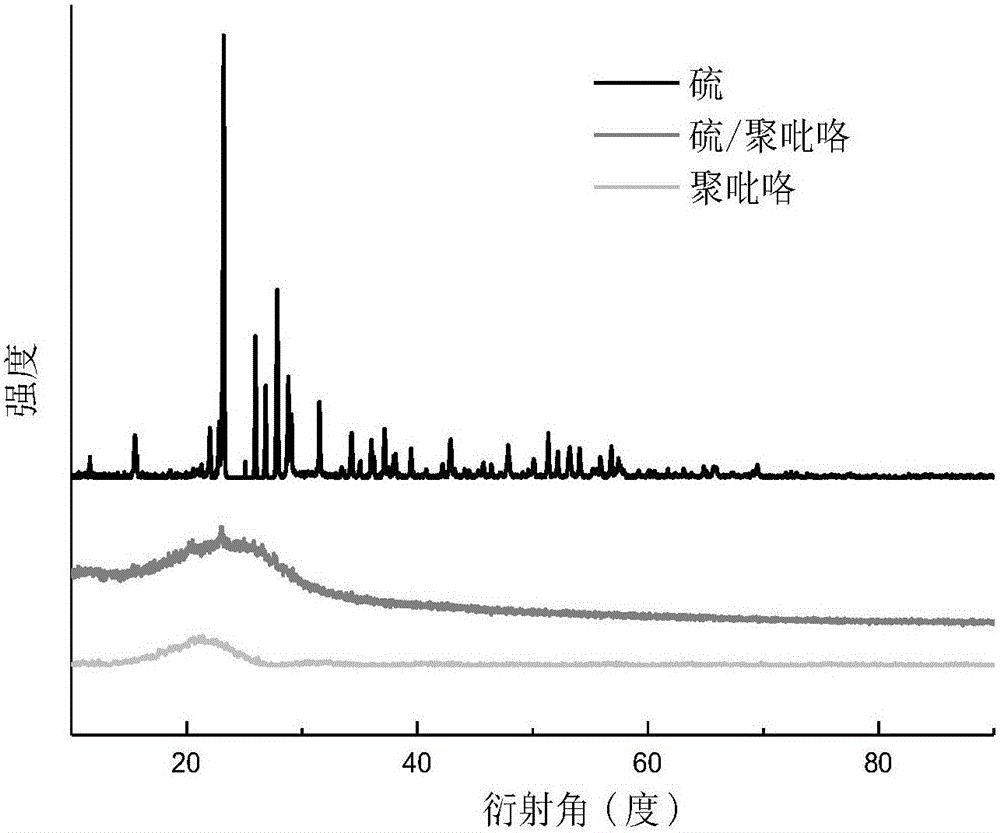

Preparation method of nano-sulfur/annular polypyrrole composite positive electrode material

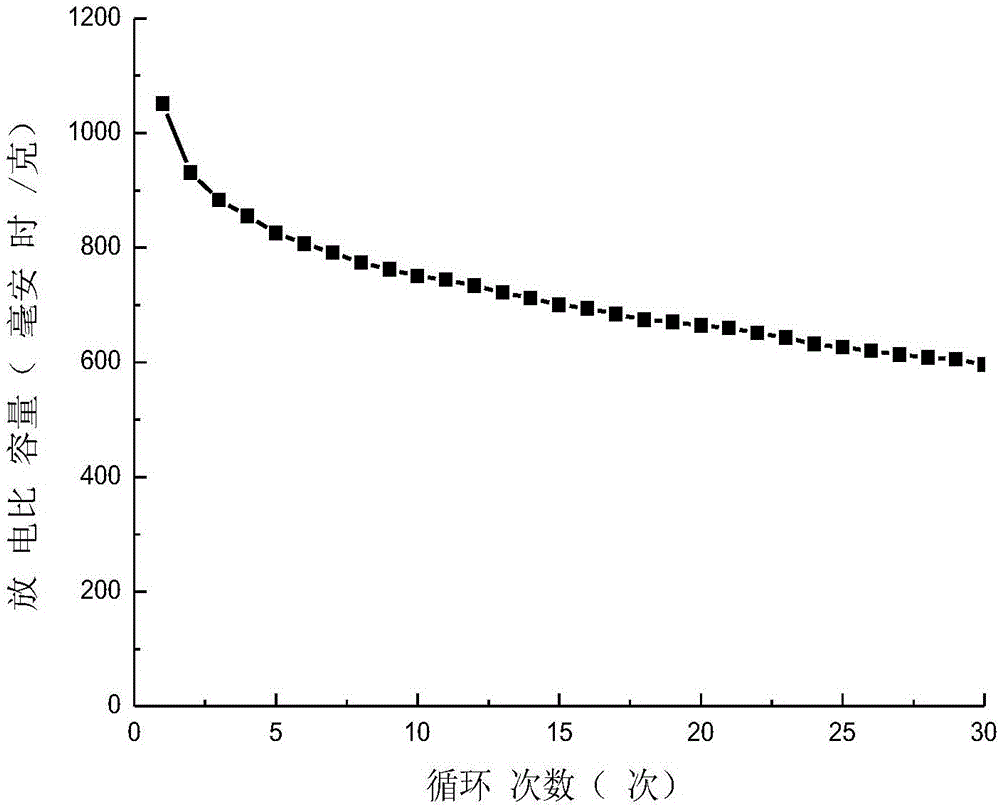

A composite positive electrode material and composite material technology, which is applied in the field of nanomaterial preparation and new energy devices, can solve the problem of volume expansion of electrode materials, and achieve the effects of small size, improved electrochemical activity, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

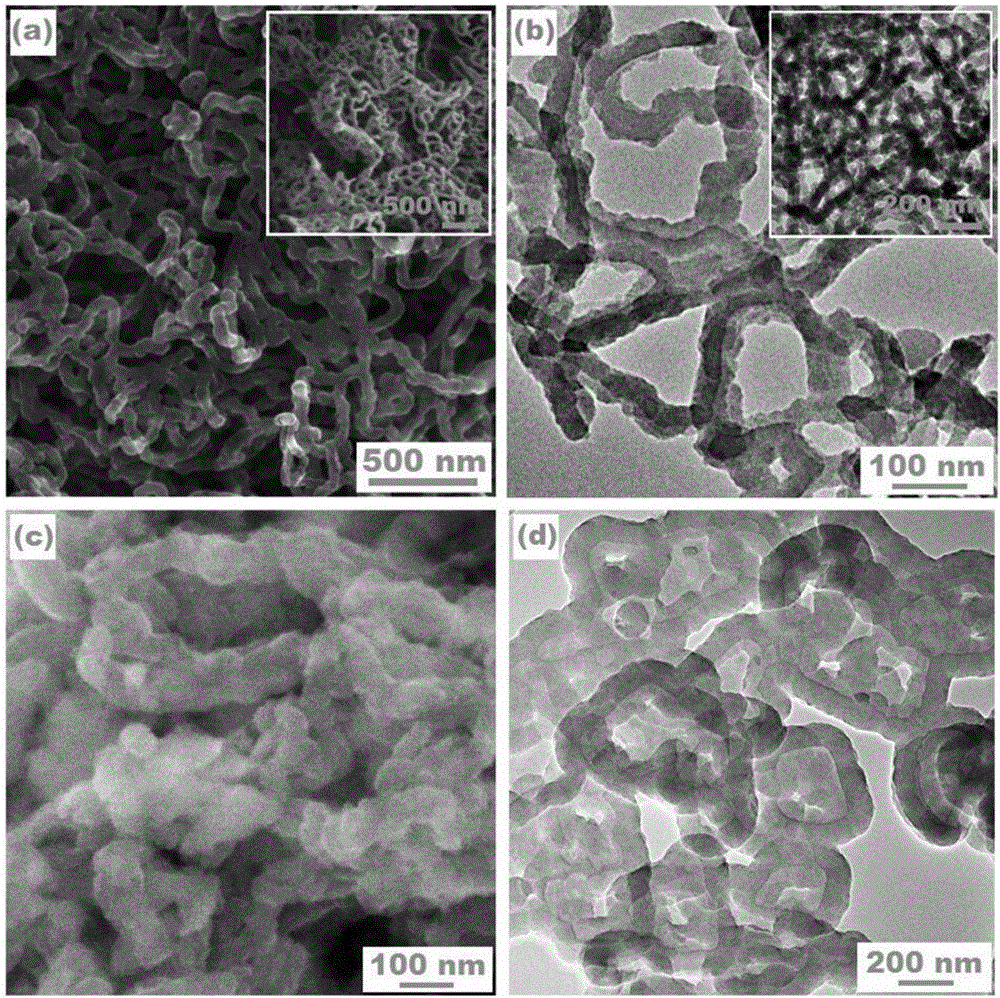

Embodiment 1

[0026] (1) Using pyrrole monomer as raw material, prepare 30mM pyrrole solution by manual stirring;

[0027] (2) Using CTAB powder as raw material, prepare 12cmcCTAB solution (wherein 1cmc=0.87mM);

[0028] (3) According to the volume ratio of the pyrrole solution and the CTAB solution being 2:1, the pyrrole solution in step 1 was added to the CTAB solution in step 2, and fully mixed for 30 minutes by magnetic stirring;

[0029] (4) prepare ammonium persulfate solution; the concentration of ammonium persulfate solution is 0.1mM;

[0030] (5) Pre-cool the solutions of step 3 and step 4 at 5°C for 2 hours;

[0031](6) According to the molar ratio of ammonium persulfate and pyrrole monomer of 1:1, add the pre-cooled ammonium persulfate solution to the mixture of pyrrole and CTAB, and fully react at 5°C for 24 hours to form a ring Polypyrrole;

[0032] (7) Suction filter the mixed solution after the reaction in step 6, and alternately wash the sediment three times with distille...

Embodiment 2

[0042] The preparation method of nano-sulfur / cyclic polypyrrole composite positive electrode material applied to lithium-sulfur batteries, the steps are the same as in Example 1, except that the CTAB concentration in step (2) is 4 cmc.

[0043] (1) Using pyrrole monomer as raw material, prepare 30mM pyrrole solution by manual stirring;

[0044] (2) Using CTAB powder as raw material, prepare 4cmcCTAB solution (wherein 1cmc=0.87mM);

[0045] (3) According to the volume ratio of the pyrrole solution and the CTAB solution being 2:1, the pyrrole solution in step 1 was added to the CTAB solution in step 2, and fully mixed for 30 minutes by magnetic stirring;

[0046] (4) prepare ammonium persulfate solution; the concentration of ammonium persulfate solution is 0.1mM;

[0047] (5) Pre-cool the solutions of step 3 and step 4 at 5°C for 2 hours;

[0048] (6) According to the molar ratio of ammonium persulfate and pyrrole monomer of 1:1, add the pre-cooled ammonium persulfate solution...

Embodiment 3

[0056] The preparation method of the nano-sulfur / cyclic polypyrrole composite cathode material applied to lithium-sulfur batteries, the steps are the same as in Example 1, the difference is that the concentration of pyrrole in step (1) is 15mM, and the concentration of CTAB in step (2) It is 4cmc.

[0057] (1) Using pyrrole monomer as raw material, prepare 15mM pyrrole solution by manual stirring;

[0058] (2) Using CTAB powder as raw material, prepare 4cmcCTAB solution (wherein 1cmc=0.87mM);

[0059] (3) According to the volume ratio of the pyrrole solution and the CTAB solution being 2:1, the pyrrole solution in step 1 was added to the CTAB solution in step 2, and fully mixed for 30 minutes by magnetic stirring;

[0060] (4) prepare ammonium persulfate solution; the concentration of ammonium persulfate solution is 0.1mM;

[0061] (5) Pre-cool the solutions of step 3 and step 4 at 5°C for 2 hours;

[0062] (6) According to the molar ratio of ammonium persulfate and pyrrole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com