Proton conductor low-temperature solid oxide cell with integrated components and preparation of proton conductor low-temperature solid oxide cell

A solid oxide and proton conductor technology, applied in solid electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve the problems of poor stability of SOCs, high operating temperature, poor activity, etc., and achieve low operating temperature, low operating temperature, The effect of stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Using high-purity BaCO 3 , ZrO 2 , and Y 2 o 3 powder (analytically pure), according to the chemical formula BaZr 0.9 Y 0.1 o 3 The stoichiometric ratio was weighed and the ingredients were weighed; then it was wet-milled for 5 hours in a ball mill tank with absolute ethanol as a medium, dried, and roasted for 10 hours in an air atmosphere at 1200°C; the prepared powder was placed in a ball mill tank Using absolute ethanol as the medium, wet grinding for 2 hours, mixing evenly, drying, and then pressing to obtain a green body; finally, the green body was sintered at 1350°C for 10 hours to obtain BaZr 0.9 Y 0.1 o 3 Material.

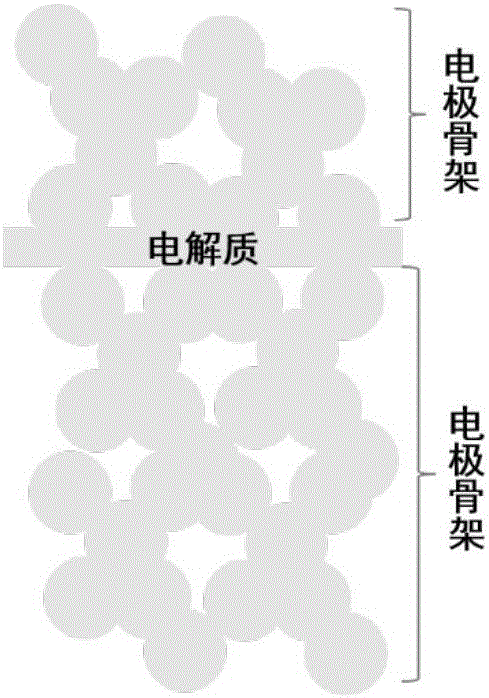

[0042] 75% BaZr 0.9 Y 0.1 o 3 +25% carbon is obtained by dry pressing to obtain a 0.5mm thick substrate, and then pressed into pure BaZr 0.9 Y 0.1 o 3 , the third layer is paved with 85% BaZr 0.9 Y 0.1 o 3 +15% Carbon. By sintering at 1600°C for 10 hours, the electrode-supported SOCs with electrolyte layer density of 96% and elect...

Embodiment 2

[0047] Prepare BaCe with embodiment 1 step 0.8 Y 0.2 o 3 Material. 65% BaCe 0.8 Y 0.2 o 3 +35% carbon is obtained by dry pressing to obtain a 0.5mm thick substrate, and then pressed into pure BaCe 0.8 Y 0.2 o 3 , the third layer is paved with 75% BaCe 0.8 Y 0.2 o 3 +25% carbon. By sintering at 1500°C for 10 hours, the electrode-supported SOCs with electrolyte layer density of 98% and electrode layer porosity of 40% were obtained.

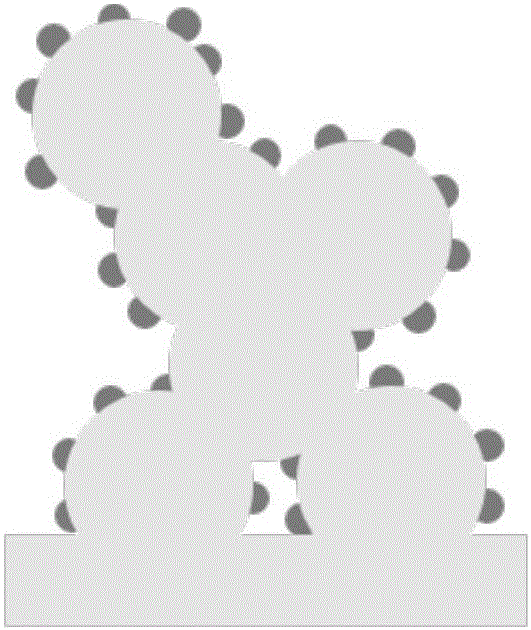

[0048] Ni(NO 3 ) 3 Immersed into the porous electrode layer and baked at 800°C to obtain an integrated proton conductor low-temperature solid oxide battery composed of an electrocatalyst whose shape is nano-particles in the electrode layer.

Embodiment 3

[0050] Prepare SrCe with embodiment 1 step 0.95 Yb 0.05 o 3 Material. 55%SrCe 0.95 Yb 0.05 o 3 +45% carbon is obtained by dry pressing to obtain a 0.5mm thick substrate, and then pressed into pure SrCe 0.95 Yb 0.05 o 3 , the third layer is paved with 60% SrCe 0.95 Yb 0.05 o 3 +40% Carbon. By sintering at 1400°C for 10 hours, the electrode-supported SOCs with electrolyte layer density of 96% and electrode layer porosity of 50% were obtained.

[0051] Fe(NO 3 ) 3 Immersed into the porous electrode layer and baked at 800°C to obtain an integrated proton conductor low-temperature solid oxide battery composed of an electrocatalyst whose shape is nano-particles in the electrode layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com