Bearing performance for compressors using high energy refrigerants with sulfur-based oil additives

A bearing performance, compressor technology, used in refrigerators, compressors, components of pumping devices for elastic fluids, etc. wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

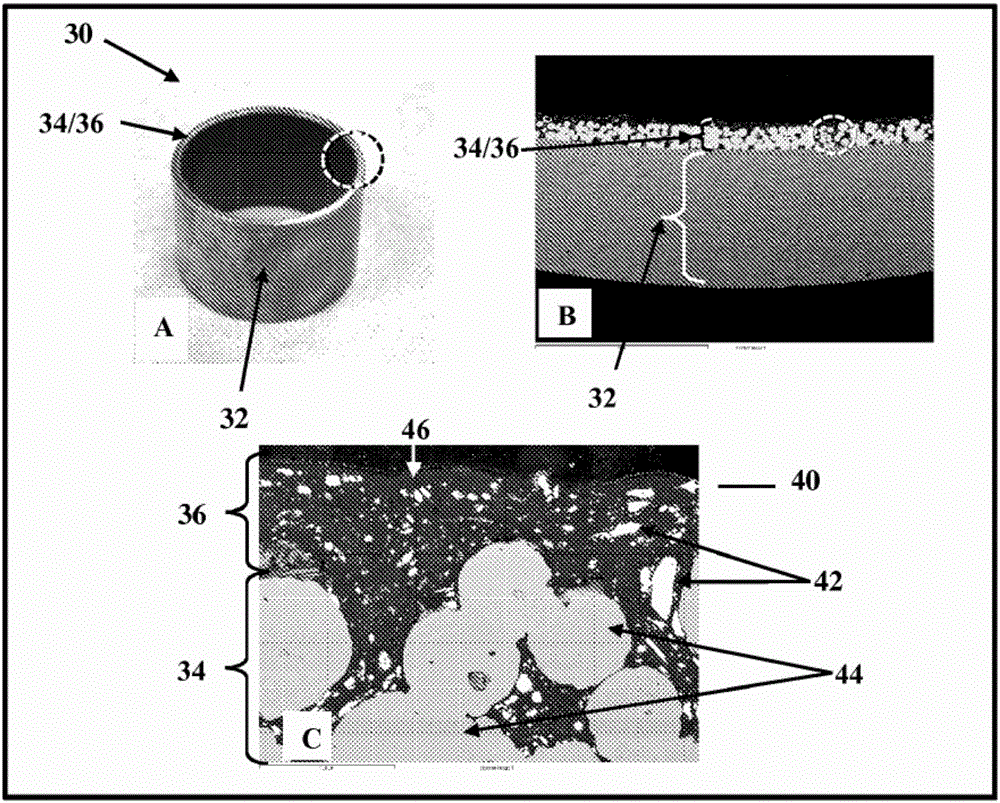

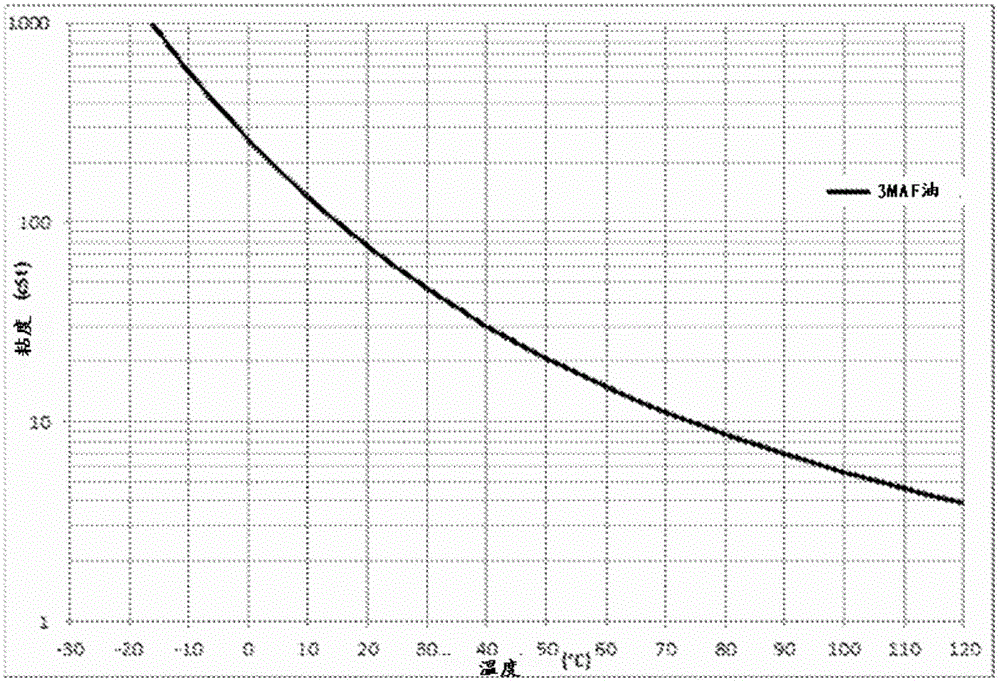

[0073] Forty machined plain bearings, including 20 conventional bearings with lead particles and 20 lead-free bearings according to certain aspects of the present disclosure, were compared by simulated early bearing performance bench testing. The bearings are typical compressor production plain bearings, consisting of a copper-bronze base with a polytetrafluoroethylene (PTFE) polymer matrix which has been machined along its surface. The 20 conventional bearings had a PTFE matrix with lead particles, while the 20 lead-free bearings had molybdenum disulfide particles in a PTFE polymer matrix. The test was performed in the presence of a polyol ester oil containing about 0.25% by weight of the oil of a sulfur additive ( 826). The oil was a mixed acid polyol ester oil (POE) with a viscosity of about 32 cSt at 40°C. The bench tests performed here were short, but partially simulated and mimicked some realistic bearing conditions in order to be able to compare the different bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com