Preparation method of compound amino acid injection containing peptides

A compound amino acid and injection technology, which is applied in the field of amino acid composition preparation, can solve the problems of poor water solubility and poor stability of amino acids, and achieve the effect of increasing solubility and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

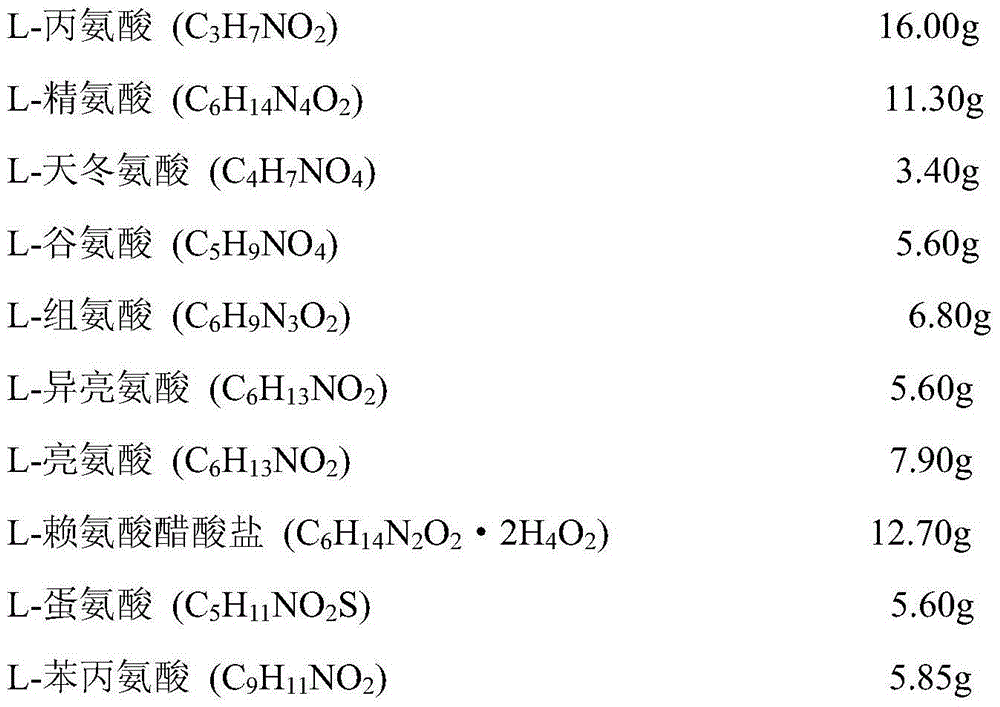

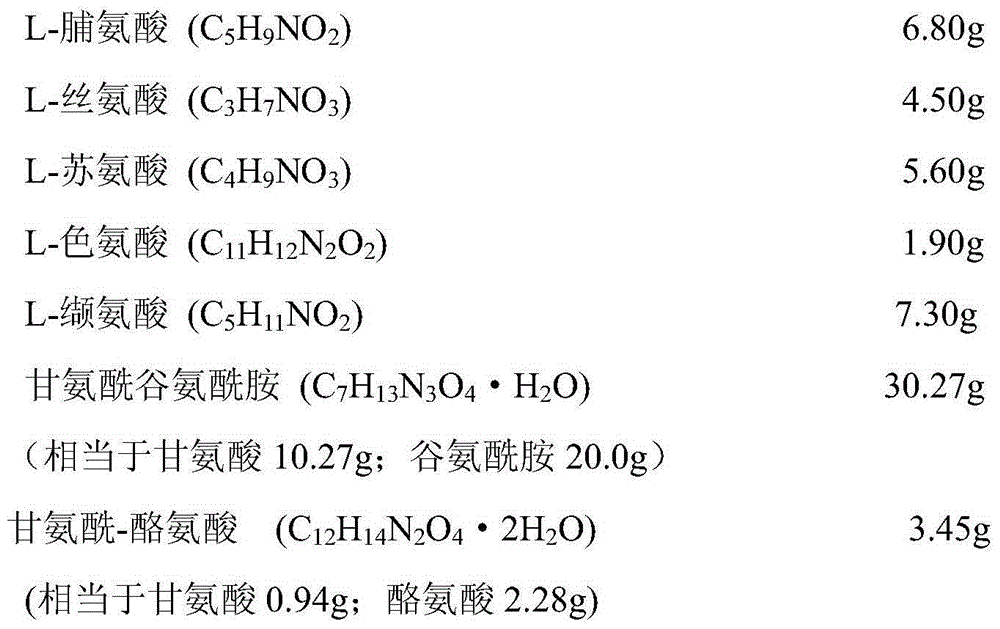

Method used

Image

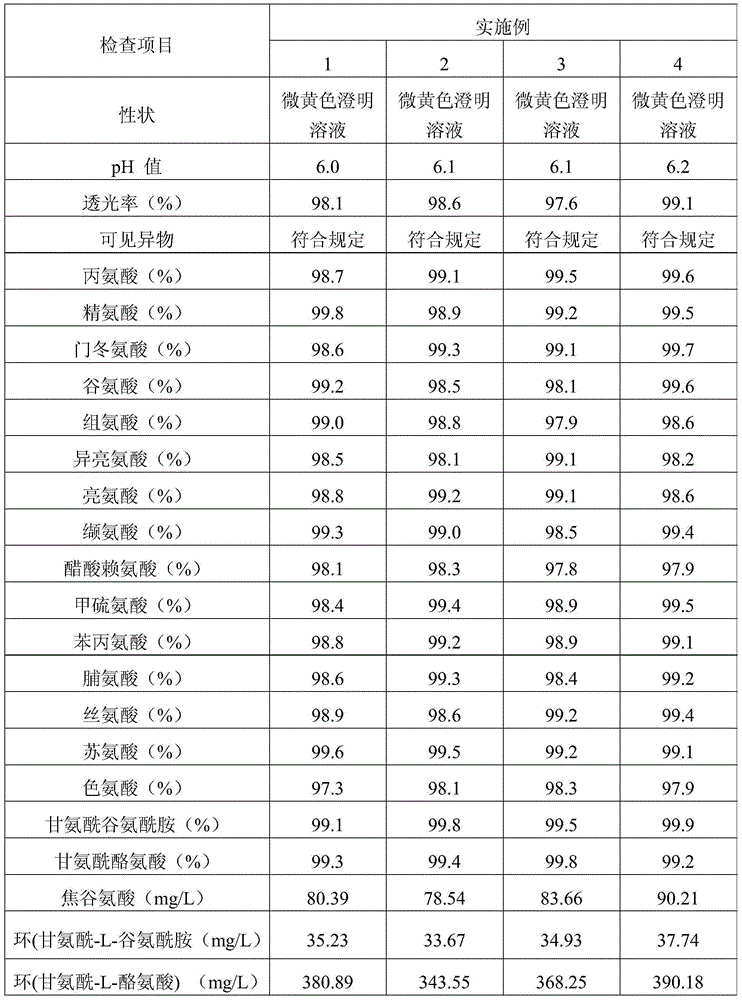

Examples

Embodiment 1

[0031] Under full nitrogen protection, take 60% of the total volume of water for injection, boil for 30 minutes, cool down to 80-100°C, add the prescribed amount of leucine, isoleucine, valine, and methionine in sequence, and stir Dissolve and clear; cool down to 65-85°C, add the prescribed amount of phenylalanine, glutamic acid, aspartic acid, lysine acetate, threonine in turn, stir to dissolve clear; cool down to 55-75°C , add the prescription amount of glycyl-L-glutamine, glycyl-L-tyrosine and arginine in turn, add the prescription amount of alanine, histidine, proline, Serine: cool down to 40-55°C, add the prescribed amount of tryptophan, stir well to obtain a compound amino acid aqueous solution, adjust the pH to 5.8 with malic acid, add 0.01% (w / v) medicinal activated carbon at 45-55°C After decolorization and endotoxin removal, use the infusion pump to circulate sequentially through a 5μm titanium rod filter, 0.45μm and 0.22μm cartridge filter, and then transport it to ...

Embodiment 2

[0034] Under full nitrogen protection, take 70% of the total volume of water for injection, boil for 45 minutes, cool down to 80-100°C, add the prescribed amount of leucine, isoleucine, valine, and methionine in sequence, and stir Dissolve and clear; cool down to 65-85°C, add the prescribed amount of phenylalanine, glutamic acid, aspartic acid, lysine acetate, threonine in turn, stir to dissolve clear; cool down to 55-75°C , add the prescription amount of glycyl-L-glutamine, glycyl-L-tyrosine and arginine in turn, add the prescription amount of alanine, histidine, proline, Serine: cool down to 40-55°C, add tryptophan in the prescribed amount, stir well to obtain a compound amino acid aqueous solution, adjust the pH to 6.0 with rosmarinic acid, add 0.02% (w / v) of the drug at 45-55°C After using activated carbon to decolorize and remove endotoxin, use an infusion pump to circulate through a 5μm titanium rod filter, 0.45μm and 0.22μm cartridge filter in sequence, and then transpo...

Embodiment 3

[0037] Under full nitrogen protection, take 80% of the total volume of water for injection, boil for 60 minutes, cool down to 80-100°C, add the prescribed amount of leucine, isoleucine, valine, and methionine in sequence, and stir Dissolve and clear; cool down to 65-85°C, add the prescribed amount of phenylalanine, glutamic acid, aspartic acid, lysine acetate, threonine in turn, stir to dissolve clear; cool down to 55-75°C , add the prescription amount of glycyl-L-glutamine, glycyl-L-tyrosine and arginine in turn, add the prescription amount of alanine, histidine, proline, Serine: cool down to 40-55°C, add the prescribed amount of tryptophan, stir evenly to obtain a compound amino acid aqueous solution, adjust the pH to 6.0 with malic acid and rosmarinic acid, add 0.05% (w / v ) of medicinal activated carbon for decolorization and endotoxin removal, and then use an infusion pump to circulate through a 5μm titanium rod filter, 0.45μm and 0.22μm cartridge filter, and then transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com