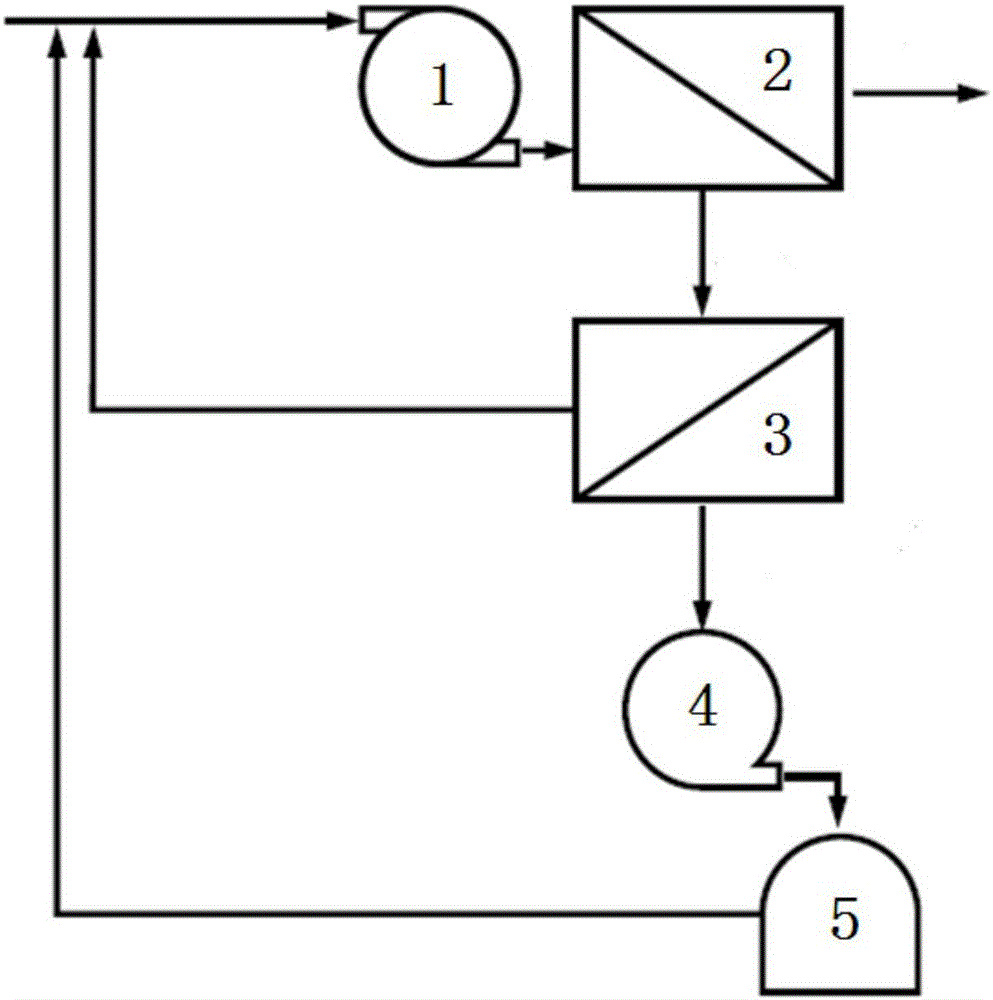

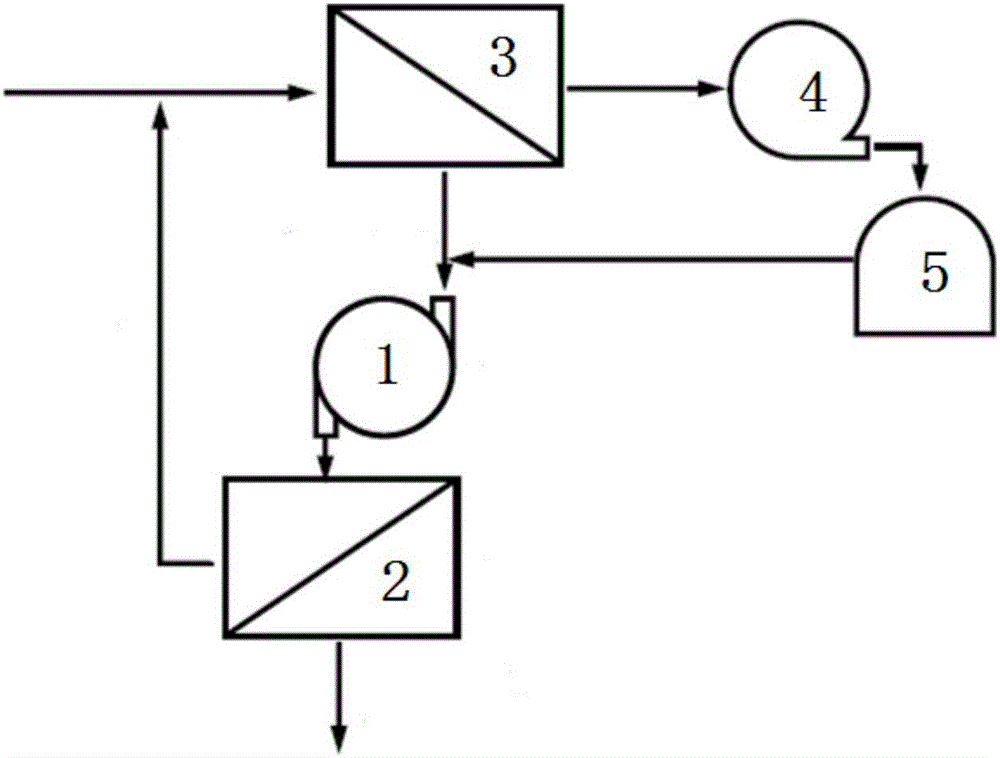

Recovery processing method and system of volatile organic compounds according to double-membrane method

A recovery and treatment technology for volatile organic compounds, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of redundant vacuum pumps, slow pressure release of oil storage tanks, low absorption efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

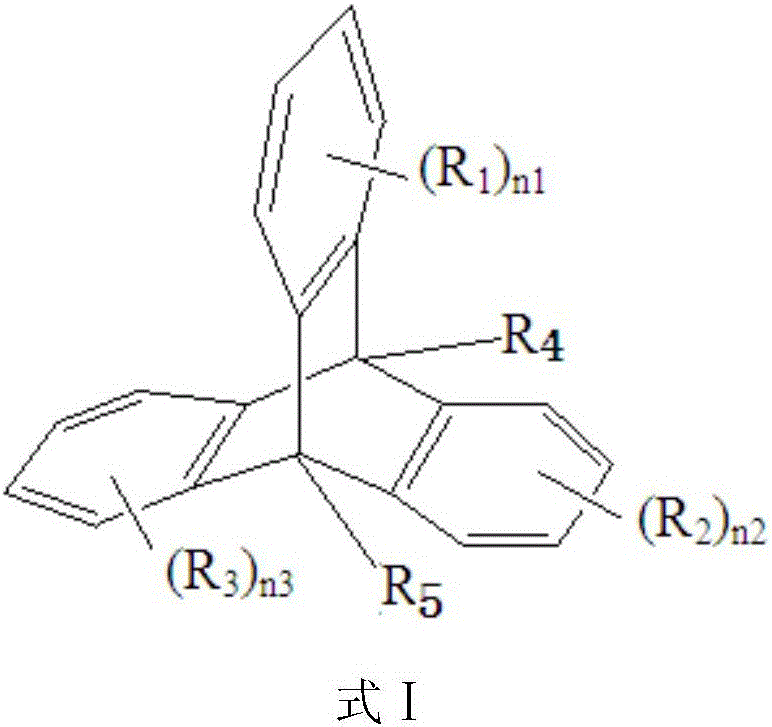

[0089] The preferential nitrogen permeable membrane separation membrane is synthesized by using 2,3,6,7-tetrahydroxytripterene and 1,7-pimeloyl chloride as the main monomers, pyridine as the acid-binding agent, and methylpyrrolidone as the solvent. , the specific steps are as follows: add 1.5mol of 2,3,6,7-tetrahydroxytripene, 3mol of pyridine, and 4.5mol of 1,7-pimeloyl chloride into the methylpyrrolidone solution and stir to dissolve. Under the condition of 2°C (nitrogen protection), react for 3.5h, and coat the reacted homogeneous polycondensation mixture on the polytetrafluoroethylene base film to prepare a composite film, put the coated composite film in a vacuum oven and dry it at 70°C , that is, a tripteryl VOCs interception type polymer separation membrane is obtained. The average pore diameter of the tripterene-based VOCs interception polymer separation membrane obtained by BET test is 2.0 nm.

[0090] The test conditions are: at 25°C, nitrogen / cyclohexane is used as...

Embodiment 2

[0094] The preferential nitrogen permeable membrane separation membrane is synthesized by using 2,3,6,7,14,15-hexaaminotriptycene and suberoyl chloride as the main monomers, pyridine as the acid-binding agent, and methylpyrrolidone as the solvent. The specific steps are as follows: 1mol of 2,3,6,7,14,15-hexaaminotriptycene, 3.5mol of pyridine, and 3mol of suberoyl chloride are added to the methylpyrrolidone solution and stirred to dissolve, and the temperature is Under the condition of 2°C (nitrogen protection), react for 3.5h, the homogeneous polycondensation mixed solution of the reaction is coated on the polytetrafluoroethylene base film to prepare a composite film, and the coated composite film is dried in a vacuum oven at 70°C. That is, a tripteryl VOCs interception type polymer separation membrane is obtained. The average pore size of the tripterene-based VOCs interception polymer separation membrane prepared by BET test was 1.6nm.

[0095] The test conditions are: at 2...

Embodiment 3

[0099] The preferential nitrogen permeable membrane separation membrane is made of 9,10-diethyl-2,3,6,7,12,13-hexahydroxytriptycene and suberoyl chloride as the main monomers, and pyridine as the acid-binding agent. Methylpyrrolidone is used as a solvent for the synthesis reaction, and the specific steps are as follows: 1mol of 9,10-diethyl-2,3,6,7,12,13-hexahydroxytriptycene, 3.5mol of pyridine, 3mol of Suberoyl chloride was added into the methylpyrrolidone solution and stirred to dissolve, and reacted for 3.5 hours at a temperature of 2°C (nitrogen protection), and the homogeneous polycondensation mixture was coated on the polytetrafluoroethylene base film to prepare a composite film. The coated composite membrane was dried in a vacuum oven at 70° C. to obtain a tripterene-based VOCs interception polymer separation membrane. The average pore size of the tripterene-based VOCs interception polymer separation membrane prepared by BET test was 1.3nm.

[0100] The test condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com