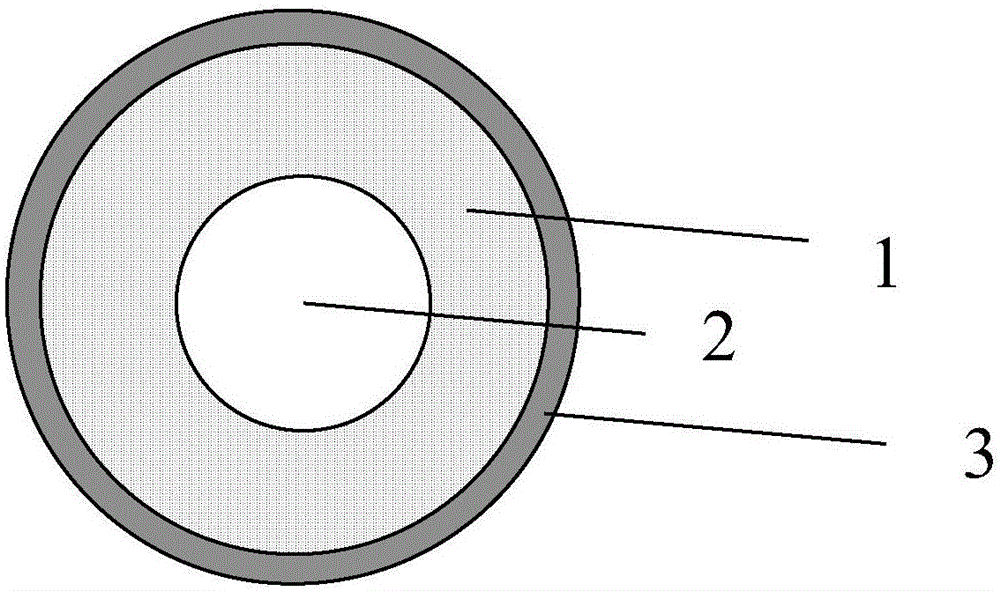

Tubular hollow fiber membrane, preparation method and application

A fiber membrane, hollow technology, applied in the field of air dehumidification system and its process, can solve the problems of droplet corrosion, high energy consumption, frosting on the surface of the cooler, etc., to avoid solution corrosion, ensure penetration efficiency, and high packing density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

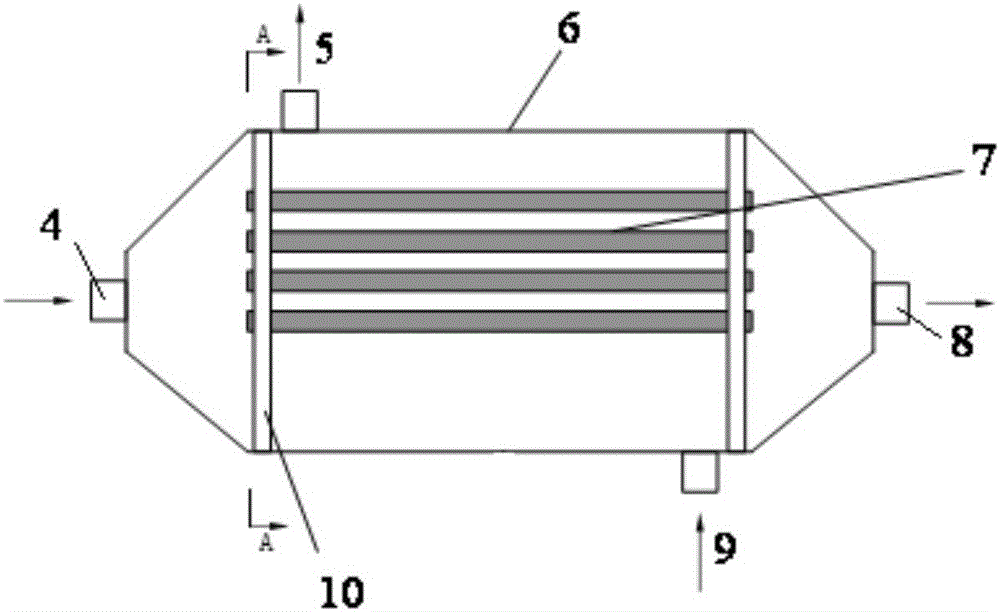

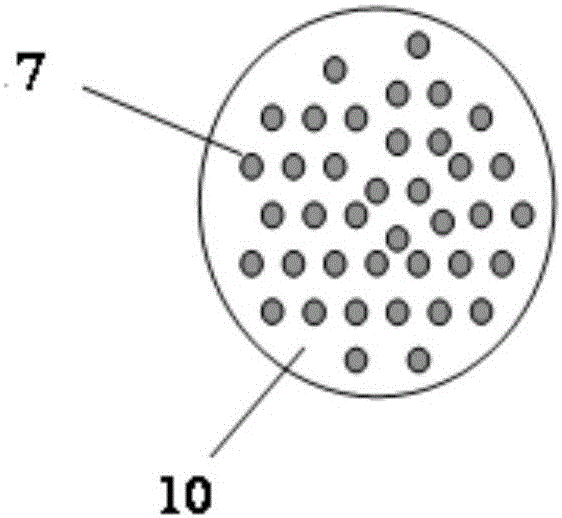

[0044] Prepare 7 g of polyvinylidene fluoride, 1 g of polyethylene glycol-2000, and 92 g of 80 wt.% N,N-dimethylformamide solution in a conical flask. Control the temperature to 60°C, fully stir for 4 hours to dissolve, and let it stand for 12 hours to defoam. It becomes a transparent and uniform casting solution. Add 5g of graphene and put it into an ultrasonic scrubber for 20 minutes. 4g of polyvinyl alcohol (PVA), 7g of dimethyl sulfoxide and 1g of lithium chloride were dissolved in 88g of water, stirred at a temperature of 80°C for one hour to obtain the pre-cortex solution, which was colorless and transparent. Then add the pre-cortex liquid into 5% glutaraldehyde solution, stir at room temperature for 2 minutes to obtain the cortex liquid, the concentration of the pre-cortex liquid in the cortex liquid is 0.3ml / 100g. Nitrogen gas was sprayed into the cavity, and the casting solution was used image 3 The nozzle shown sprays into the gel bath to form a film. Control the ...

Embodiment 2

[0047] Prepare 9 g of polyvinylidene fluoride, 1.5 g of polyethylene glycol-2000, and 90.5 g of 85 wt.% N,N-dimethylformamide solution in a conical flask. Control the temperature at 60°C, fully stir for 4 hours to dissolve, and let it stand for 12 hours to defoam. It becomes a transparent and uniform casting solution. Add 7g of graphene and put it in an ultrasonic cleaner for 20 minutes. Dissolve 4g of polyvinyl alcohol, 7g of dimethyl sulfoxide and 1g of lithium chloride in 88g of water, stir at a temperature of 80°C for one hour to obtain a pre-cortex liquid, which is colorless and transparent, and then the cortex The pre-solution was added to 5% glutaraldehyde solution, and stirred at room temperature for 2 minutes to obtain a cortex solution. The concentration of the cortex pre-solution in the cortex solution was 0.4ml / 100g. Nitrogen gas was sprayed into the cavity, and the casting solution was used image 3 The nozzle shown is sprayed into the gel bath to form a film, an...

Embodiment 3

[0050] Prepare 12g of polyvinylidene fluoride, 2g of polyethylene glycol-2000, and 84g of 90wt.% N,N-dimethylformamide solution in a conical flask. Control the temperature at 60°C, fully stir for 4 hours to dissolve, and let it stand for 12 hours to defoam. It becomes a transparent and uniform casting solution. Add 10g of copper powder and put it in an ultrasonic cleaner for 20 minutes. 4g of polyvinyl alcohol (PVA), 7g of dimethyl sulfoxide and 1g of lithium chloride were dissolved in 88g of water, stirred at a temperature of 80°C for one hour to obtain the pre-cortex solution, which was colorless and transparent. Then add the pre-cortex liquid into 5% glutaraldehyde solution, stir at room temperature for 2 minutes to obtain the cortex liquid, the concentration of the pre-cortex liquid in the cortex liquid is 0.3ml / 100g. Spray air in the inner cavity, and use the casting solution image 3 The nozzle shown is sprayed into the gel bath to form a film, and the film thickness is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Packing density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com