Method for producing hydroxylamine hydrochloride through continuous method

A continuous method of hydroxylamine hydrochloride, applied in the fields of hydroxylamine, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of small production scale, achieve the effects of increasing production capacity, increasing reaction contact area, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

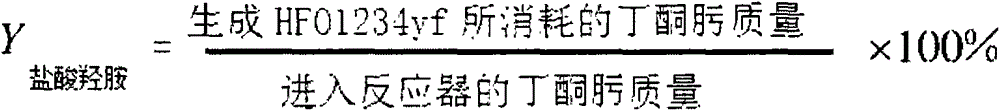

Embodiment 1

[0019] Step 1 Pretreatment of Stainless Steel Theta Ring Packing

[0020] Add 1Kg stainless steel θ ring packing in 10L reaction kettle, soak 3h in 12Kg ethanol, then add 5g of 1-aminoethyl-3-methylimidazole nitrate in ethanol solution, filter, dry to obtain the described of pretreated fillers.

[0021] Step 2 synthesis reaction

[0022] Mix 10Kg of butanone oxime with hydrochloric acid (concentration: 25% by mass), and pass it into a 2L fixed-bed reactor equipped with 1L of pretreated filler for reaction. The molar ratio of butanone oxime to hydrochloric acid is 1:3, the reaction temperature is 80°C, and the reaction space velocity of the mixed solution is 3h -1 , the reaction pressure is normal pressure, and the reaction product undergoes rectification and crystallization refining process to obtain the refined product of hydroxylamine hydrochloride. Excess hydrochloric acid is recycled as supplementary raw material, numbered M-1.

Embodiment 2

[0024] Step 1 Pretreatment of Stainless Steel Theta Ring Packing

[0025] Add 1Kg stainless steel θ ring packing in 10L reactor, soak 1h in 9Kg ethanol, then add 1-aminoethyl-3-methylimidazole nitrate that is 1g in ethanol solution, filter, dry, obtain described of pretreated fillers.

[0026] Step 2 synthesis reaction

[0027] 10Kg of butanone oxime and hydrochloric acid (mass percentage concentration 20%) were mixed and passed into a 2L fixed-bed reactor equipped with 0.6L of pretreated filler for reaction. The molar ratio of butanone oxime to hydrochloric acid is 1:1, the reaction temperature is 60°C, and the reaction space velocity of the mixed solution is 1h -1 , the reaction pressure is normal pressure, and the reaction product undergoes rectification and crystallization refining process to obtain the refined product of hydroxylamine hydrochloride. Excess hydrochloric acid is recycled as supplementary raw material, coded as M-2.

Embodiment 3

[0029] Step 1 Pretreatment of Stainless Steel Theta Ring Packing

[0030] Add 1Kg stainless steel θ ring filler in 10L reaction kettle, soak in 15Kg ethanol for 5h, then add 10g of 1-aminoethyl-3-methylimidazole nitrate in ethanol solution, filter, dry to obtain the described of pretreated fillers.

[0031] Step 2 synthesis reaction

[0032] Mix 10Kg of butanone oxime with hydrochloric acid (concentration: 30% by mass), and pass it into a 2L fixed-bed reactor equipped with 1.8L of pretreated filler for reaction. The molar ratio of butanone oxime to hydrochloric acid is 1:5, the reaction temperature is 100°C, and the reaction space velocity of the mixed solution is 5h -1 , the reaction pressure is normal pressure, and the reaction product undergoes rectification and crystallization refining process to obtain the refined product of hydroxylamine hydrochloride. Excess hydrochloric acid is recycled as a supplementary raw material, numbered M-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com