A kind of polyurethane type high refraction sulfur-containing optical resin monomer and preparation method thereof

An optical resin, high refraction technology, used in 2 fields, can solve the problems of inability to use optical materials, and achieve the effects of high purity, low yellowness index, and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

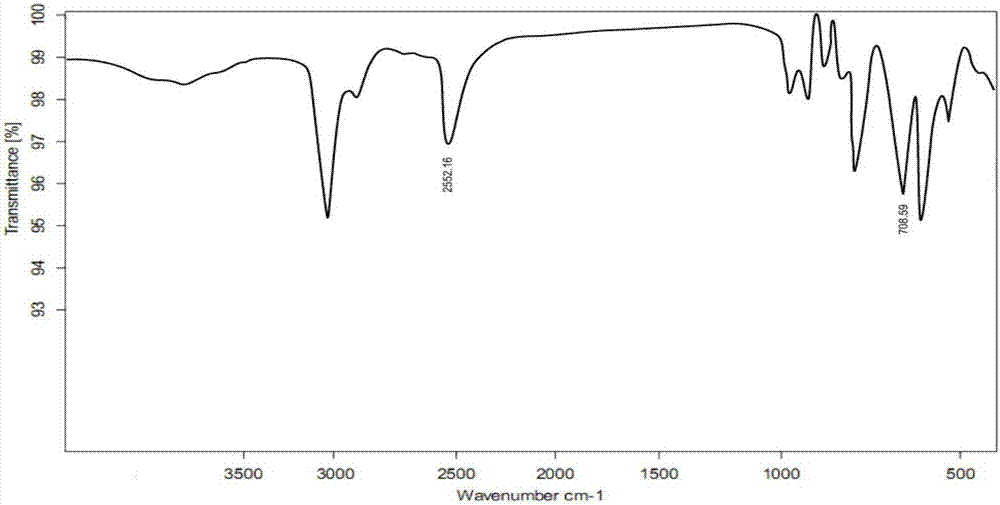

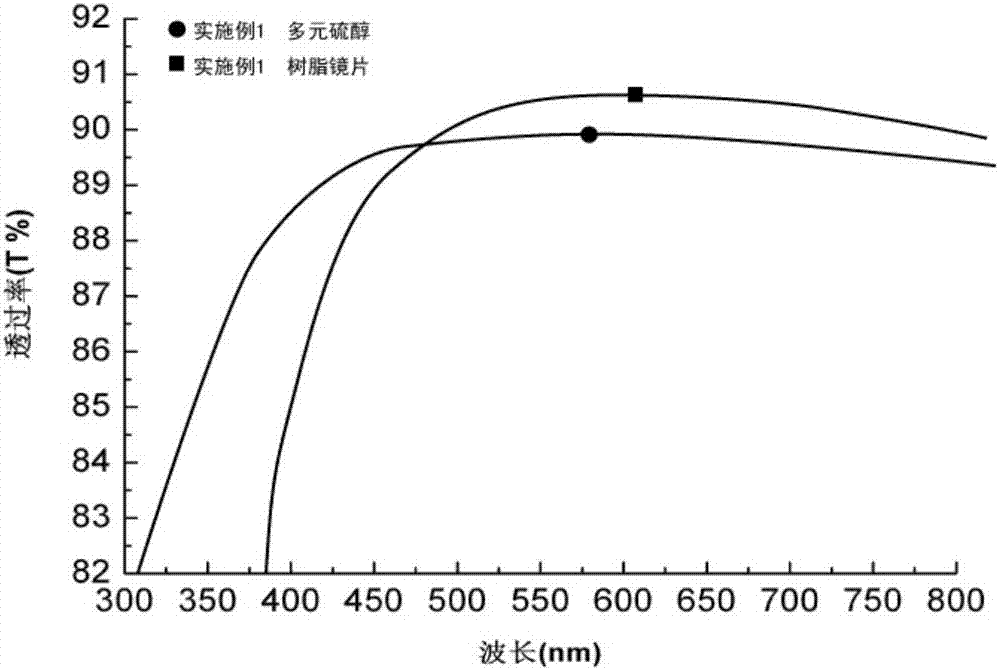

[0036] Embodiment 1: prepare 2,3-dimercaptoethylthiopropanethiol compound and polyurethane lens

[0037] (1) Preparation of 2,3-dimercaptoethylthiopropanethiol compound:

[0038] ① Mix and stir 100g of mercaptoethanol (ME) and 15g of 35wt% sodium hydroxide (NaOH) aqueous solution, control the temperature of the water bath at 46°C, add 70g of epichlorohydrin slowly within 30min, keep warm at 46°C for 100min, and the sodium salt precipitates . Then add 30g of 35wt% NaOH solution dropwise, after the color of the system turns from reddish to colorless, stir for 10 minutes, slowly add 124g of concentrated hydrochloric acid, evaporate water and by-products under reduced pressure, and then filter to remove sodium chloride to obtain sulfur generation of polyols.

[0039] ② Mix and stir 30g of thiopolyol, 34g of thiourea and 49g of concentrated hydrochloric acid, raise the temperature to 110°C, reflux for 6 hours, and stop heating. After the system cools down to 65°C, keep it warm, ...

Embodiment 2

[0047] Embodiment 2: prepare 2,3-dimercaptoethylthiopropanethiol compound and polyurethane lens

[0048] (1) Preparation of 2,3-dimercaptoethylthiopropanethiol compound:

[0049] ①Mix and stir 100g of mercaptoethanol (ME) and 12g of 35wt% sodium hydroxide (NaOH) aqueous solution, control the temperature of the water bath at 46°C, add 62g of epichlorohydrin slowly within 30min, keep warm at 46°C for 120min, and the sodium salt precipitates . Then add 24g of 35wt% NaOH solution dropwise, after the color of the system turns from reddish to colorless, stir for 10 minutes, slowly add 118g of concentrated hydrochloric acid, evaporate water and by-products under reduced pressure, and filter to remove sodium chloride to obtain sulfur generation of polyols.

[0050] ② Mix and stir 30g of thiopolyol, 30g of thiourea and 36g of concentrated hydrochloric acid, raise the temperature to 110°C, reflux for 5 hours, and stop heating. After the system cools down to 65°C, keep it warm, and ke...

Embodiment 3

[0053] Embodiment 3: prepare 2,3-dimercaptoethylthiopropanethiol compound and polyurethane lens

[0054] (1) Preparation of 2,3-dimercaptoethylthiopropanethiol compound:

[0055] ① Mix and stir 100g of mercaptoethanol (ME) and 20g of 35wt% sodium hydroxide (NaOH) aqueous solution, control the temperature of the water bath at 46°C, add 85g of epichlorohydrin slowly within 30min, keep warm at 46°C for 110min, and the sodium salt precipitates . Then add 40g of 35wt% NaOH solution dropwise, after the color of the system turns from reddish to colorless, stir for 10 minutes, slowly add 130g of concentrated hydrochloric acid, evaporate water and by-products under reduced pressure, and then filter to remove sodium chloride to obtain sulfur generation of polyols.

[0056] ② Mix and stir 30g of thiopolyol, 45g of thiourea and 59g of concentrated hydrochloric acid, raise the temperature to 110°C, reflux for 8 hours, and stop heating. After the system cools down to 70°C, keep it warm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com