Preparation method of diesel oil additive, prepared diesel oil additive and application of diesel oil additive

An additive and diesel technology, which is applied in the preparation of diesel additives and in the field of diesel additives, can solve the problems of not increasing the added value of diesel, not producing economic benefits, and unsatisfactory performance, so as to achieve flexible addition methods, improve low-temperature fluidity of diesel, The effect of reducing the average wear scar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

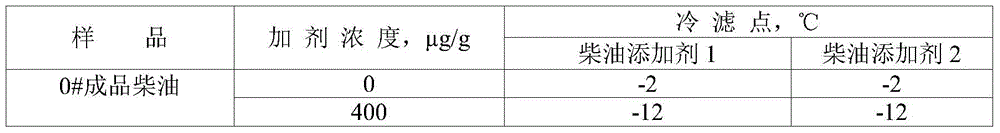

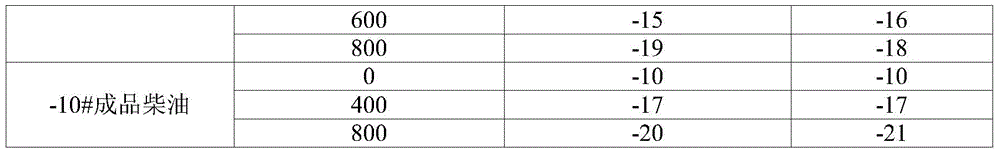

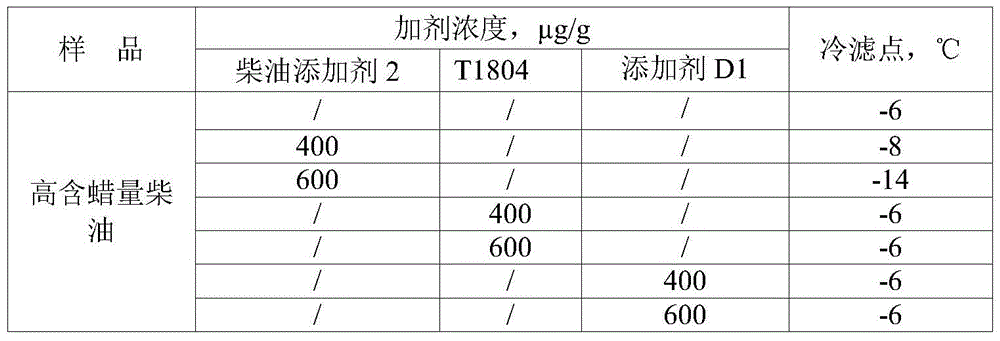

[0018] The first aspect of the present invention: provide a kind of preparation method of diesel oil additive, it is characterized in that, this method comprises: carry out polymerization reaction after mixing maleic anhydride, acrylate, methyl oleate, initiator and organic solvent, obtain maleic acid Acid anhydride-acrylic acid ester-methyl oleate terpolymer as diesel oil additive; Wherein, the molar ratio of described maleic anhydride, acrylate and methyl oleate is 1:(0.5-3):(0.5-3), Preferably 1: (1.5-2.5): (1.5-2.5), the acrylate is acrylic acid and C 12 -C 18 obtained from the esterification of alcohols.

[0019] According to the first aspect of the present invention, the polymerization reaction is a free radical reaction, and a compound that is easily decomposed into free radicals (primary free radicals) by heat can be added, that is, a free radical initiator, also referred to as an initiator, to initiate the reaction. For example, the initiator can be benzoyl peroxide...

Embodiment 1

[0033] Mix acrylic acid, n-dodecyl alcohol, p-toluenesulfonic acid and hydroquinone, and carry out esterification reaction under reflux at about 120°C for 1 hour until the amount of water obtained in the esterification reaction is close to the theoretical value, to obtain lauryl acrylate; among them, acrylic acid The molar ratio with n-dodecyl alcohol is 1:1, the addition of p-toluenesulfonic acid is 0.5% of the total mass of acrylic acid and n-dodecyl alcohol, and the addition of hydroquinone is 0.5% of the total mass of acrylic acid and n-dodecyl alcohol. 1%.

[0034] After mixing formic acid, methanol, and concentrated sulfuric acid (98% by mass) with 6% by mass of oleic acid in a molar ratio of 2:1, add water-carrying agent toluene, and carry out esterification reaction at about 140°C for 2 hours to obtain methyl oleate ester.

[0035] After mixing the prepared lauryl acrylate, methyl oleate and maleic anhydride in a molar ratio of 1:2:2, add 1% benzyl peroxide to the tot...

Embodiment 2

[0037] Mix stearyl acrylate, methyl oleate and maleic anhydride purchased from Bailingwei Technology Co., Ltd. at a molar ratio of 1:2:2, and then add maleic anhydride, stearyl acrylate and methyl oleate to form a total 1% of the mass of azobisisobutylcyanide and 50% of the mass of xylene were polymerized for 6 hours at about 120°C under the protection of nitrogen to obtain maleic anhydride-octadecyl acrylate-methyl oleate The meta-copolymer is used as diesel additive 2 with a flash point of 65°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com