High-viscosity optical film tape and manufacturing process thereof

A technology of optical film and manufacturing process, applied in the direction of film/sheet adhesive, non-polymer adhesive additive, adhesive, etc., can solve the problem of low bonding strength, achieve high peel strength and high conversion rate , The effect of increasing the peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

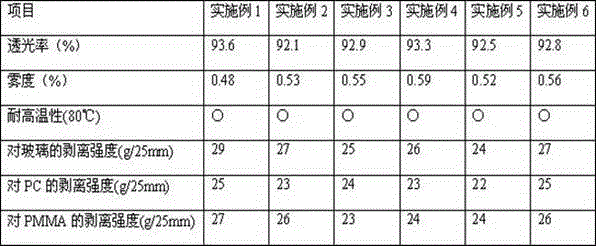

Examples

Embodiment 1

[0053] A high-viscosity optical film tape, comprising a light-release film layer, an optical adhesive layer and a heavy-release film layer arranged sequentially from top to bottom, the optical adhesive layer is made of an adhesive, and the adhesive includes The following components by weight:

[0054] 40 parts of butyl methacrylate

[0055] 20 parts ethyl acrylate

[0056] Tricarboxymethylpropane triacrylate 15 parts

[0057] Acrylic 5 parts

[0058] 4 parts melamine formaldehyde resin

[0059] 2 parts triethylenetetramine

[0060] Nano silicon dioxide 3 parts

[0061] Initiator 1 part.

[0062] The present application may further include commonly used adhesive additives, the addition of which will not cause essential changes in the present invention.

[0063] Wherein, the particle size of the nano silicon dioxide is 50nm.

[0064] Wherein, the initiator is dimethyl azobisisobutyrate.

[0065] Wherein, the preparation process of the adhesive includes the following ste...

Embodiment 2

[0073] The difference between this embodiment and embodiment 1 is:

[0074] In this embodiment, the adhesive comprises the following components by weight:

[0075] 50 parts of butyl methacrylate

[0076] 20 parts ethyl acrylate

[0077] Tricarboxymethylpropane triacrylate 20 parts

[0078] 3 parts acrylic

[0079] 5 parts melamine formaldehyde resin

[0080] 4 parts triethylenetetramine

[0081] Nano silicon dioxide 5 parts

[0082] Initiator 2 parts.

[0083] Wherein, the particle size of the nano silicon dioxide is 30nm.

[0084] Wherein, the initiator is benzoyl peroxide.

[0085] Wherein, the preparation process of the adhesive includes the following steps: adding various raw material components in proportion, blowing in nitrogen, stirring, and cooling to room temperature after complete reaction at 85° C. to obtain the adhesive.

[0086] The present invention also provides a manufacturing process of high-viscosity optical film adhesive tape, comprising the followi...

Embodiment 3

[0094] The difference between this embodiment and embodiment 1 is:

[0095] A high-viscosity optical film tape, comprising a light-release film layer, an optical adhesive layer and a heavy-release film layer arranged sequentially from top to bottom, the optical adhesive layer is made of an adhesive, and the adhesive includes The following components by weight:

[0096] 30 parts of butyl methacrylate

[0097] 15 parts ethyl acrylate

[0098] Tricarboxymethylpropane triacrylate 10 parts

[0099] Acrylic 8 parts

[0100] 2 parts melamine formaldehyde resin

[0101] 1 part triethylenetetramine

[0102] Nano silicon dioxide 1 part

[0103] Initiator 2 parts.

[0104] Wherein, the particle size of the nano silicon dioxide is 70nm.

[0105] Wherein, the initiator is at least one of azodiisopropylimidazoline hydrochloride.

[0106] Wherein, the preparation process of the adhesive includes the following steps: adding various raw material components in proportion, blowing in ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com