Method for preparing functional peptide from royal jelly

A royal jelly and functional peptide technology, applied in the field of bioengineering, can solve the problems of no reported preparation method of royal jelly protein peptide, no report of hypoglycemic activity of royal jelly protein peptide, etc., so as to promote agricultural quality and efficiency, increase utilization value, Scientific and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, a kind of method utilizing royal jelly to prepare functional peptide, carries out following steps successively:

[0030] Weigh 1.0kg of royal jelly (pH 3.8), add 1.0kg of water and stir evenly, heat up to 37°C, then add 10g of acid protease (50,000 U / g), adjust the pH to 3.5 with 0.1mol / L HCl, and The enzymolysis reaction was incubated (37° C.) for 4 hours with stirring.

[0031] After the enzymatic hydrolysis reaction time is up, the enzymatic hydrolysis reaction product is rapidly heated (heating rate: 10°C / min) to 90°C and kept for 10 minutes, and then cooled (heating rate: 10°C / min) to room temperature to terminate the enzymolysis reaction. Adopt J-6M large-capacity refrigerated centrifuge (BECKMAN company) to centrifuge under the condition of rotating speed 3000r / min and 4 ℃ for 20min, obtain supernatant 1.2kg, this supernatant is the enzymolysis solution containing royal jelly functional peptide.

[0032] Under the working pressure of 0.1-0.2Mpa and...

Embodiment 2

[0034] Embodiment 2, a kind of method utilizing royal jelly to prepare functional peptide, carries out following steps successively:

[0035] Weigh 2.0kg of royal jelly (pH value 3.8) with Example 1, add 2.0kg of water and stir evenly, heat up to 40°C, then add 20g of acid protease (50,000 U / g), and use 0.1moL / L of HCl to adjust the pH The value was 4.0, and the enzymolysis reaction was incubated (40° C.) for 4 hours under stirring conditions.

[0036] Subsequent steps are the same as in Example 1.

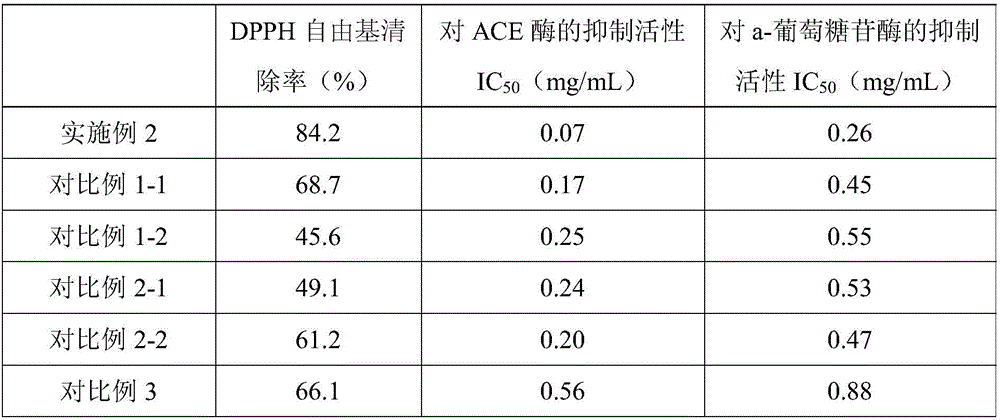

[0037] Finally, 158g of royal jelly functional peptide powder was obtained, the peptide content was 92.8%, the color was milky white, the flavor was pure and harmonious, and slightly frankincense. The royal jelly peptide powder was dissolved to a concentration of 1.0 mg / mL, and its DPPH free radical scavenging rate was measured to be 84.2%; at the same concentration of 1.0 mg / mL, the inhibitory activity IC of the active peptide on ACE enzyme was detected by HPLC 50 0.07mg / mL; wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com