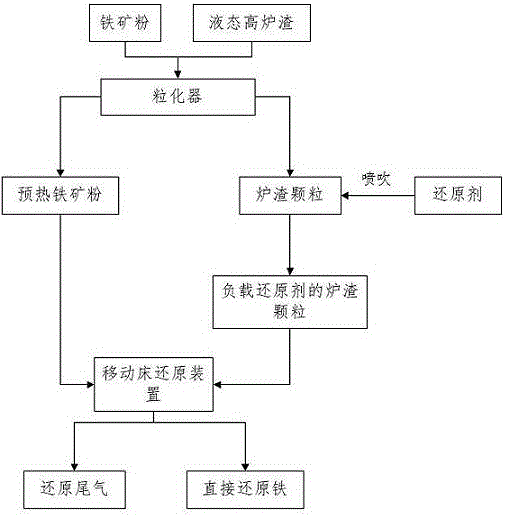

Direct-reduction ironmaking device and method based on blast furnace slag waste heat utilization

A blast furnace slag, direct technology, applied in the field of direct reduction iron making equipment, can solve the problems of increasing equipment investment and operating costs, waste of sensible heat, large power consumption, etc., so as to improve heat and mass transfer efficiency, reduce production costs, promote The effect of tar decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

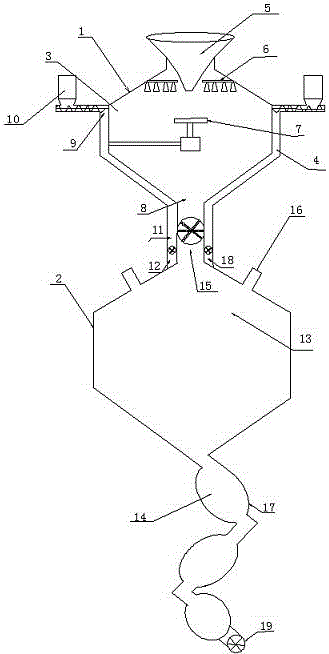

[0031] A direct reduction ironmaking device based on utilization of blast furnace slag waste heat, the device includes a granulation device 1 and a moving bed reduction device 2; the granulation device 1 includes an inner layer granulation zone 3 and an outer layer iron ore powder preheating zone 4, There is a liquid blast furnace slag inlet 5 on the top of the granulation device 3, a reducing agent sprayer 6 is installed on the upper part of the inner layer granulation area 3, a granulation plate 7 is arranged on the middle part, and a granulated slag outlet 8 is arranged on the bottom; the outer iron ore powder The upper part of the preheating zone 4 has an iron ore powder inlet 9 connected to the screw feeder 10, and the lower part has a preheated iron ore powder outlet 11 connected to the preheated iron ore powder inlet 12 of the moving bed reduction reaction device 2;

[0032] The upper part of the moving bed reduction reaction device 2 is a premixing zone 13, and the lowe...

example 2

[0039] A method of direct reduction ironmaking based on utilization of waste heat of blast furnace slag described in this embodiment comprises the following steps:

[0040] (1) The liquid blast furnace slag discharged from the blast furnace is divided into multiple slag streams with a diameter of 10mm through the slag ditch, and enters the granulator for granulation. During the granulation process, plastic cracking oil is sprayed on the slag surface according to 100% of the slag quality, The generated granulated slag, which is loaded with municipal solid waste pyrolysis tar on the surface, has a temperature of 1200°C and a particle size of less than 2mm, and is discharged from the granulator;

[0041] (2) The slag particles loaded with plastic cracking oil enter the moving bed reduction reaction device, and are uniformly mixed with the preheated iron ore powder as a heat carrier according to the mass ratio of slag and iron ore powder at 2:1, and the plastic cracking oil is in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com