Method for preparing super-microporous flexible carbon cloth and product thereof and application

An ultra-microporous, flexible technology, used in textiles and papermaking, heating/cooling fabrics, fabric surface trimming, etc., can solve the problems of limited commercial application, complex preparation process, complex preparation process, etc., to achieve excellent cycle performance, synthesis Simple method, cheap method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

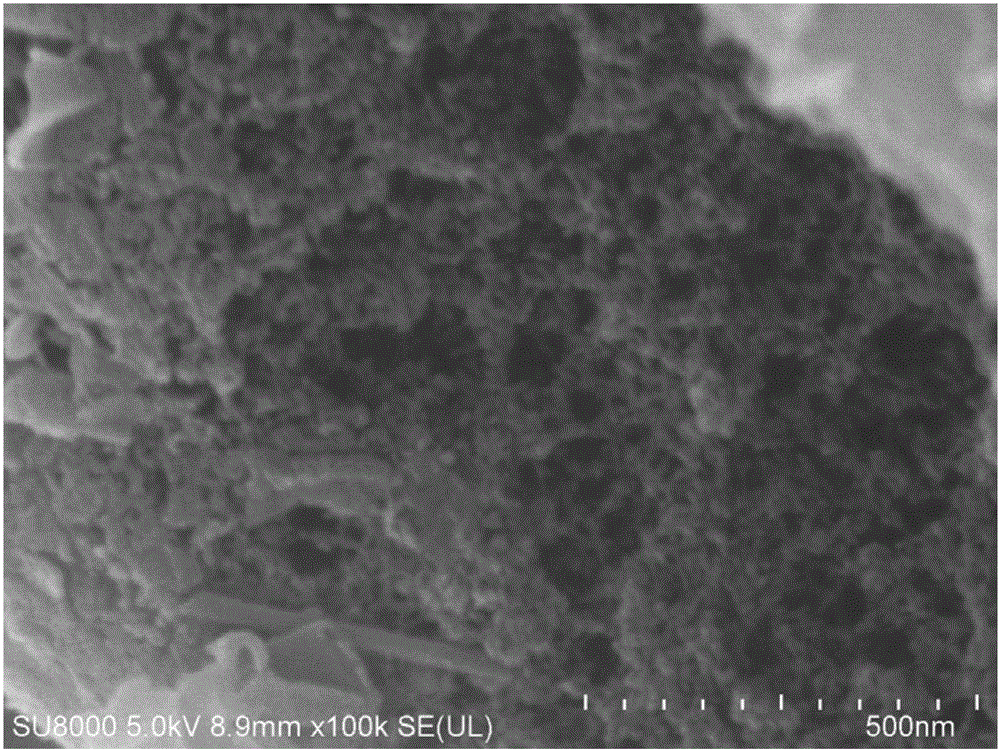

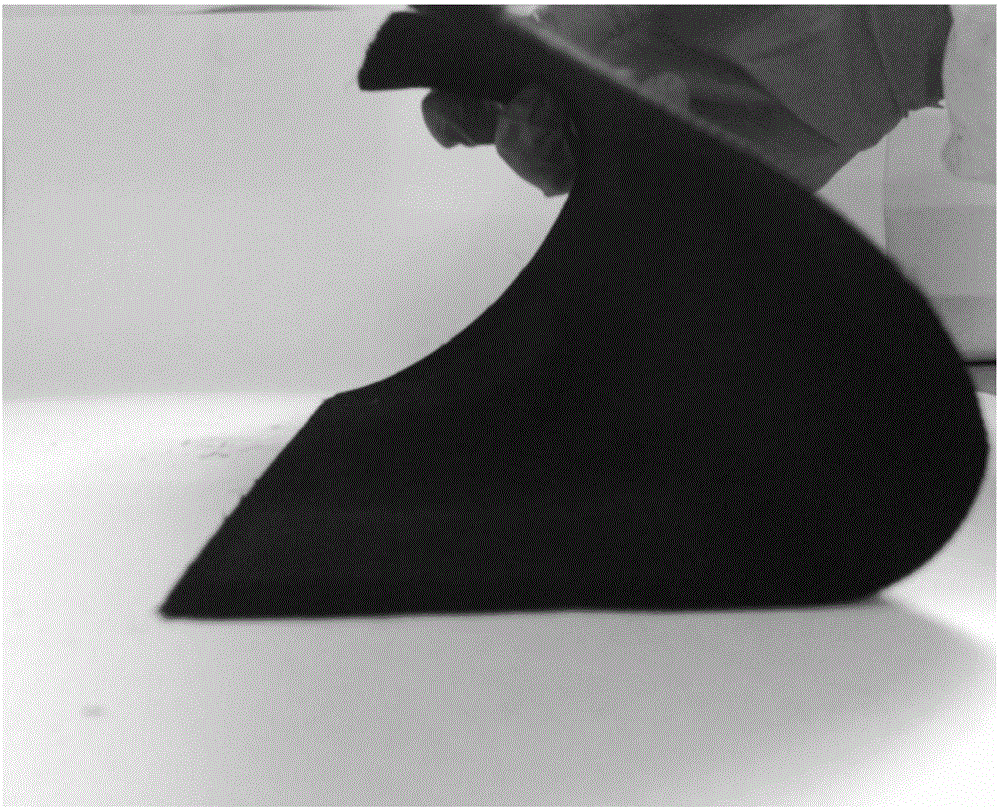

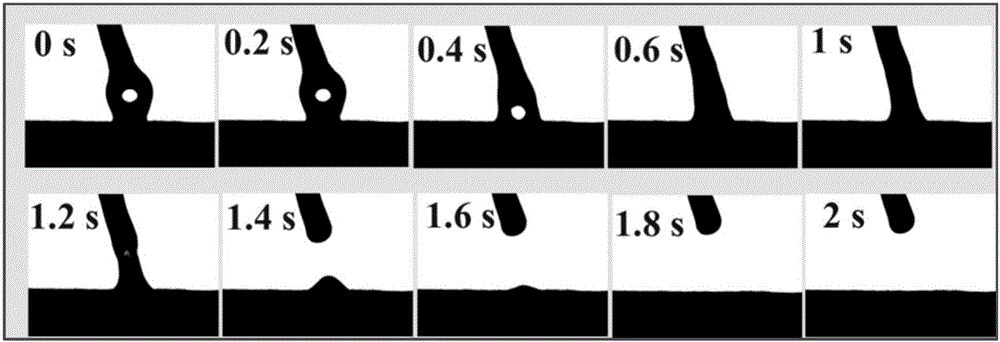

[0043] The commercial hydrophobic carbon cloth was washed with deionized water and calcined to 1000 °C in nitrogen for 4 h. SEM image see figure 1 . We can see the obvious channel structure. With the scanning electron microscope figure of comparative example 1 such as Figure 11 As shown, it can be seen that the carbon cloth has no pore structure before calcination, and the ultra-microporous flexible carbon cloth obtained after calcination, the micropores and ultra-micropores on the surface are conducive to the transport of electrolyte. like figure 2 It can be obtained that the prepared ultramicroporous flexible carbon cloth has the characteristics of large-scale synthesis, and has good flexibility and can be bent at various angles. like image 3 It can be obtained that the prepared ultramicroporous flexible carbon cloth exhibits superhydrophilic properties, and the contact angle with water is 0 degree. Nitrogen adsorption and desorption curve see Figure 4 , it can be...

Embodiment 2

[0045] The commercial hydrophobic carbon cloth was washed with deionized water and calcined to 1000 °C in argon for 1 h. Nitrogen adsorption and desorption curve see Image 6 , mainly micropores, the specific surface can reach 500m 2 / g. For the pore size distribution see Figure 7 It can be seen that there are a large number of micropores and ultramicropores (<0.7nm pores), and such a pore structure has a great contribution to the capacitance. It shows that the surface area and pore structure can be adjusted by adjusting the calcination time and calcination gas.

Embodiment 3

[0047] The commercial hydrophobic carbon cloth was washed with deionized water, and calcined at 800 °C for 1 h in a nitrogen:oxygen ratio of 100:1. Nitrogen adsorption and desorption curve see Figure 8 , it can be seen that it is mainly micropores, and the specific surface can reach 126m 2 g. For the pore size distribution see Figure 9 , no ultramicropores (pores < 0.7 nm) were seen. It shows that the surface area and pore structure can be adjusted by adjusting the calcination temperature and calcination gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com