Graphene composite nano gold thin film flexible strain sensor manufacturing method and strain sensor thereof

A graphene composite, strain sensor technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of decreased sensitivity of the strain sensor, insignificant change of the resistance of wrinkled graphene, etc., and achieves low cost, easy operation, good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

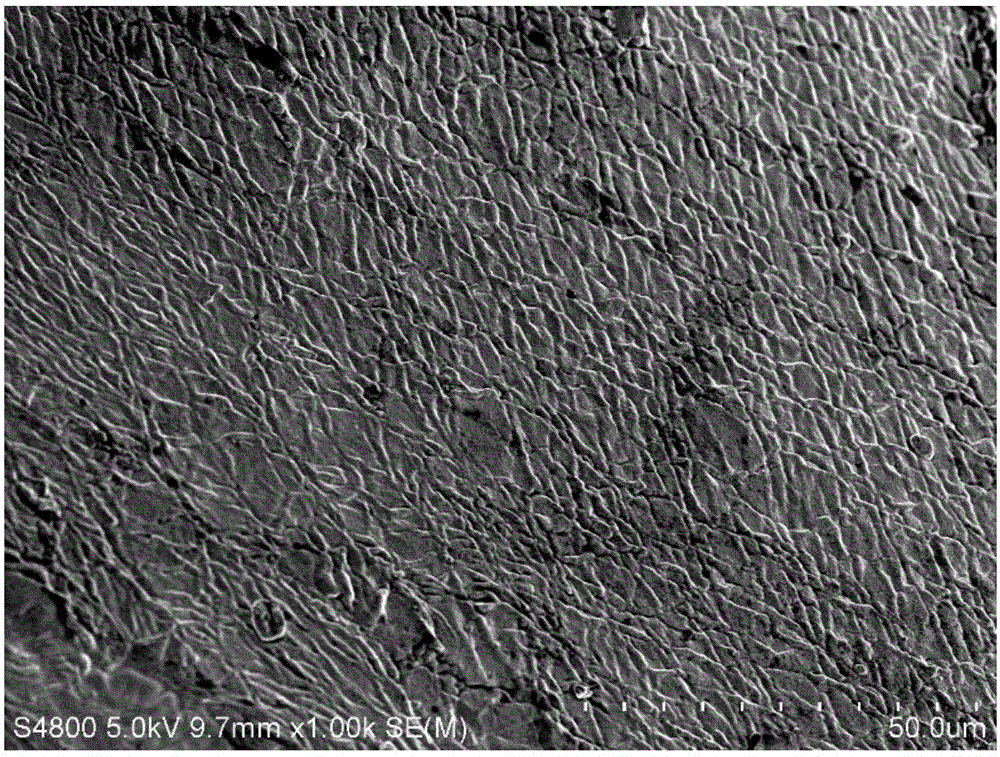

[0026] figure 1 The scanning electron microscope (SEM) figure of the graphene composite nano-gold film flexible film prepared for the preferred embodiment 1 of the preparation method of the graphene composite nano-gold film flexible strain sensor of the present invention, in the present embodiment: 30 * 30mm 2 Small and large copper foils were cleaned with alcohol and acetone and placed in the middle of the quartz tube of a tube furnace. Turn on the vacuum pump, and raise the temperature of the tube furnace to 1100° C. under a hydrogen atmosphere of 10 sccm, with a heating rate of 10° C. / min. When the copper foil reaches the target temperature, 10 sccm of methane is introduced, and the methane is turned off after 20 minutes. Under the hydrogen atmosphere, the single-layer graphene was obtained on the copper foil with the furnace cooling down. When the selected copper foil grows, the side that is not attached to the quartz tube is spin-coated with polymethyl methacrylate, nam...

Embodiment 2

[0028] In this embodiment, the experimental conditions for preparing the PDMS film of the graphene composite nano-gold film are the same as in Example 1. Coating silver paste on both ends of the PDMS film of the graphene composite nano-gold film, and connecting copper wires, a new type of graphene composite nano-gold film flexible strain sensor is obtained.

Embodiment 3

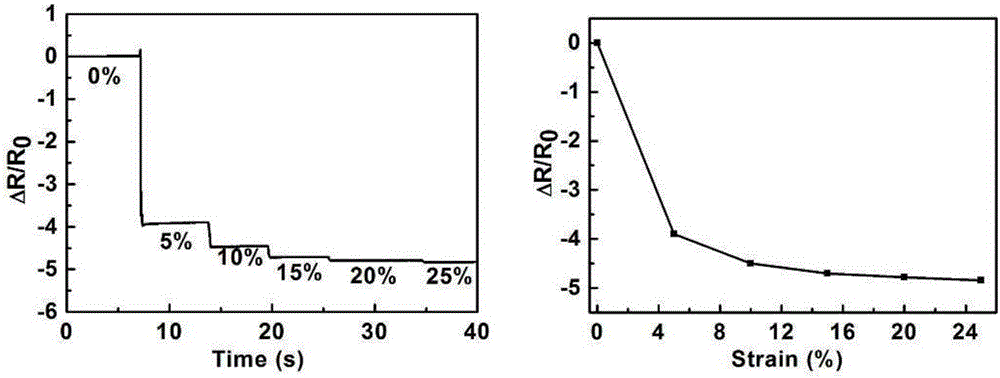

[0030] In this embodiment, the experimental conditions for preparing the PDMS film of the graphene composite nano-gold film are the same as in Example 1. The two ends of the PDMS film of the graphene composite nano-gold film are coated with silver paste and connected with a copper wire to obtain a flexible strain sensor of the graphene composite nano-gold film. Connect the two ends of the copper wire to the working electrode and the reference electrode of the electrochemical workstation respectively, and make it produce a strain from 0% to 25% by stretching the strain sensor, and the current change recorded on the electrochemical workstation is the result The "strain-resistance change curve", such as figure 2 shown. This curve shows that the sensitivity of the graphene-composite gold nano-film flexible strain sensor is very high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com