Instant papaya pickles and production method thereof

A production method and technology of papaya, applied in the field of instant papaya pickles and its production, to achieve the effects of rich nutrition, low price and improved comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

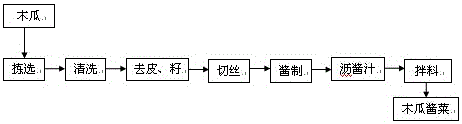

Image

Examples

Embodiment 1

[0060] A spiced instant papaya pickle consists of the following raw materials: 90kg papaya, 100kg light soy sauce, 1.0kg five-spice powder, 3.5kg white sugar, 3kg edible oil, 0.1kg monosodium glutamate, 0.5kg garlic, 0.15kg ginger powder, and 0.5kg peanut kg, sesame 0.5kg, wine 1kg, soybean paste 20kg.

[0061] The garlic is minced garlic or minced garlic; the wine is common white wine; the sesame seeds are fried and crushed; the edible oil is rapeseed oil.

[0062] After the peanuts are fried, they are pulverized.

[0063] The preparation method is as follows: 1) selection of raw materials: select papaya with fresh color and no browning of the fruit, and discard papaya that is too old, rotten and has insect eyes;

[0064] 2) Peeling and seeding: Peel off the outer skin with a peeler, cut in half, and remove the middle grain;

[0065] 3) Shred: Cut the papaya into (0.2-0.3) cm×(2-3) cm lengths with a shredder;

[0066] 4) Sauce making: Put the processed raw materials into t...

Embodiment 2

[0073] A spiced instant papaya pickle consists of the following raw materials: 110kg papaya, 150kg light soy sauce, 1.5kg five-spice powder, 4.5kg white sugar, 3.5kg edible oil, 0.25kg monosodium glutamate, 1.5kg garlic, 0.3kg ginger powder, peanut 1.0kg, sesame 1.0kg, wine 1.5kg, soybean paste 30kg.

[0074] The garlic is minced garlic or minced garlic; the wine is common white wine; the sesame seeds are fried and crushed; the edible oil is rapeseed oil.

[0075] After the peanuts are fried, they are pulverized.

[0076] The preparation method is as follows: 1) selection of raw materials: select papaya with fresh color and no browning of the fruit, and discard papaya that is too old, rotten and has insect eyes;

[0077] 2) Peeling and seeding: Peel off the outer skin with a peeler, cut in half, and remove the middle grain;

[0078] 3) Shred: Cut the papaya into (0.2-0.3) cm×(2-3) cm lengths with a shredder;

[0079] 4) Sauce making: Put the processed raw materials into the...

Embodiment 3

[0086] A spiced ready-to-eat papaya pickle consists of the following raw materials: 100kg papaya, 120kg light soy sauce, 1.3kg five-spice powder, 4kg white sugar, 3.2kg edible oil, 0.2kg monosodium glutamate, 1kg garlic, 0.2kg ginger powder, and 0.8kg peanut , sesame 0.7kg, wine 1.2kg, soybean paste 25kg.

[0087] The garlic is minced garlic or minced garlic; the wine is common white wine; the sesame seeds are fried and crushed; the edible oil is rapeseed oil.

[0088] After the peanuts are fried, they are pulverized.

[0089] The preparation method is as follows: 1) selection of raw materials: select papaya with fresh color and no browning of the fruit, and discard papaya that is too old, rotten and has insect eyes;

[0090] 2) Peeling and seeding: Peel off the outer skin with a peeler, cut in half, and remove the middle grain;

[0091] 3) Shred: Cut the papaya into (0.2-0.3) cm×(2-3) cm lengths with a shredder;

[0092] 4) Sauce making: Put the processed raw materials int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com