Graphene conductive composite material filter cloth for electric sludge dewatering equipment and its manufacturing method, installation and use method

A conductive composite material and sludge dehydration technology, applied in water/sludge/sewage treatment, separation methods, chemical instruments and methods, etc., can solve problems such as short service life of anodes, reduced equipment efficiency, and sludge pollution, and achieve The effect of prolonging the service life, simplifying the structure and reducing the loss cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of graphene conductive composite material filter cloth of the present invention, it is made as follows:

[0042] (1), preparation of graphene aqueous solution

[0043] Weigh 20mg reduced graphene oxide powder, graphene quantum dot powder obtained by oxidizing 10mg graphene with concentrated sulfuric acid or a mixed acid of concentrated sulfuric acid and concentrated nitric acid, wherein the carbon and oxygen atomic content ratio is 20:1, the average The lateral dimension is about 10 nm. The above two powders were added to 40 mL of deionized water to prepare a mixed suspension of graphene and graphene quantum dots, and the suspension was ultrasonically dispersed to obtain a stably dispersed graphene aqueous solution.

[0044] (2) Fabrication of graphene conductive composite material filter cloth

[0045] Soak the polypropylene fiber (polypropylene fiber) filter cloth in the graphene aqueous solution for 8 hours, take it out, bake it at 120° C. for 8 hours, and t...

Embodiment 2

[0049]A kind of graphene conductive composite material filter cloth of the present invention, it is made as follows:

[0050] (1), preparation of graphene aqueous solution

[0051] Weigh 5mg of graphene powder prepared by liquid phase exfoliation, and 30mg of graphene oxide obtained by DMF solvothermal cutting of graphene quantum dot powder, wherein the carbon and oxygen atomic content ratio is 5:1, and the average lateral size is about 2nm . The above two powders were added to 40 mL of deionized water to prepare a mixed suspension of graphene and graphene quantum dots, and the suspension was ultrasonically dispersed to obtain a stably dispersed graphene aqueous solution.

[0052] (2) Fabrication of graphene conductive composite material filter cloth

[0053] Soak the polypropylene fiber (polypropylene fiber) filter cloth in the graphene aqueous solution for 10 hours, take it out, bake it at 80°C for 6 hours, and then make the graphene conductive composite material filter cl...

Embodiment 3

[0057] A kind of graphene conductive composite material filter cloth of the present invention, it is made as follows:

[0058] (1), the reduced graphene oxide powder is uniformly dispersed in the organic solvent N-methylpyrrolidone (NMP) by an ultrasonic dispersion method to obtain a stably dispersed graphene dispersion;

[0059] (2) Fabrication of graphene conductive composite material filter cloth

[0060] Soak the polypropylene fiber (polypropylene fiber) filter cloth in the graphene dispersion for 6 hours, take it out, and bake it at 160° C. for 10 hours to make a graphene conductive composite material filter cloth. The filter cloth has good water permeability and electrical conductivity.

[0061] The above-mentioned graphene conductive composite material filter cloth is installed and used as follows:

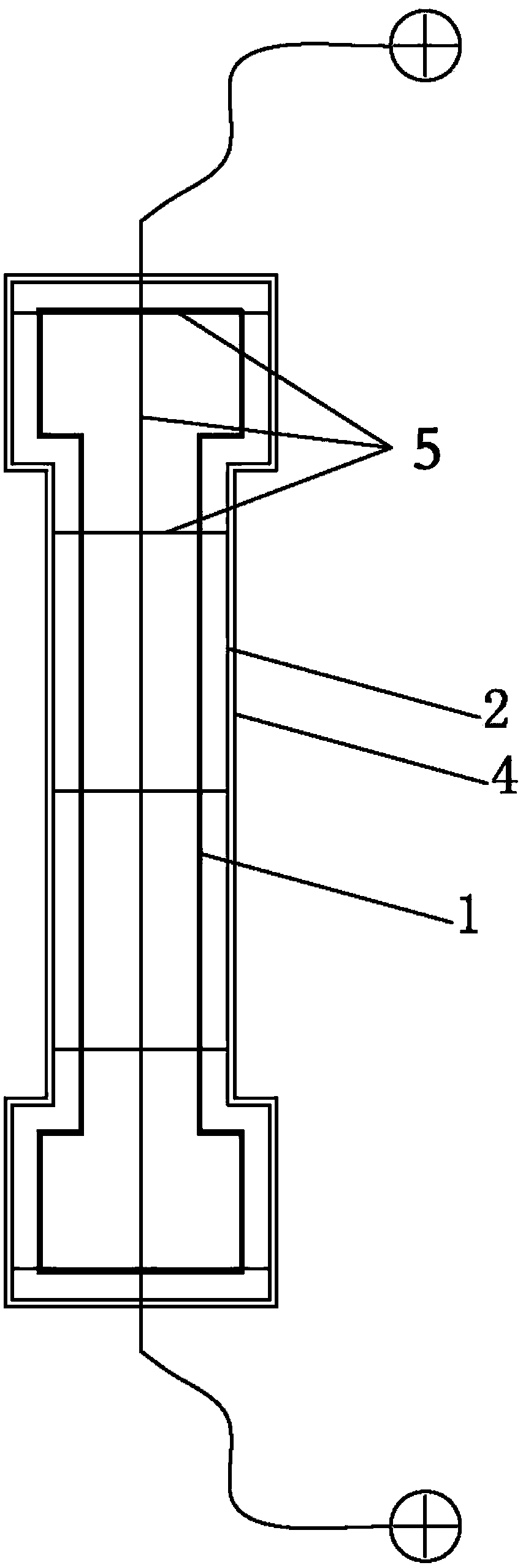

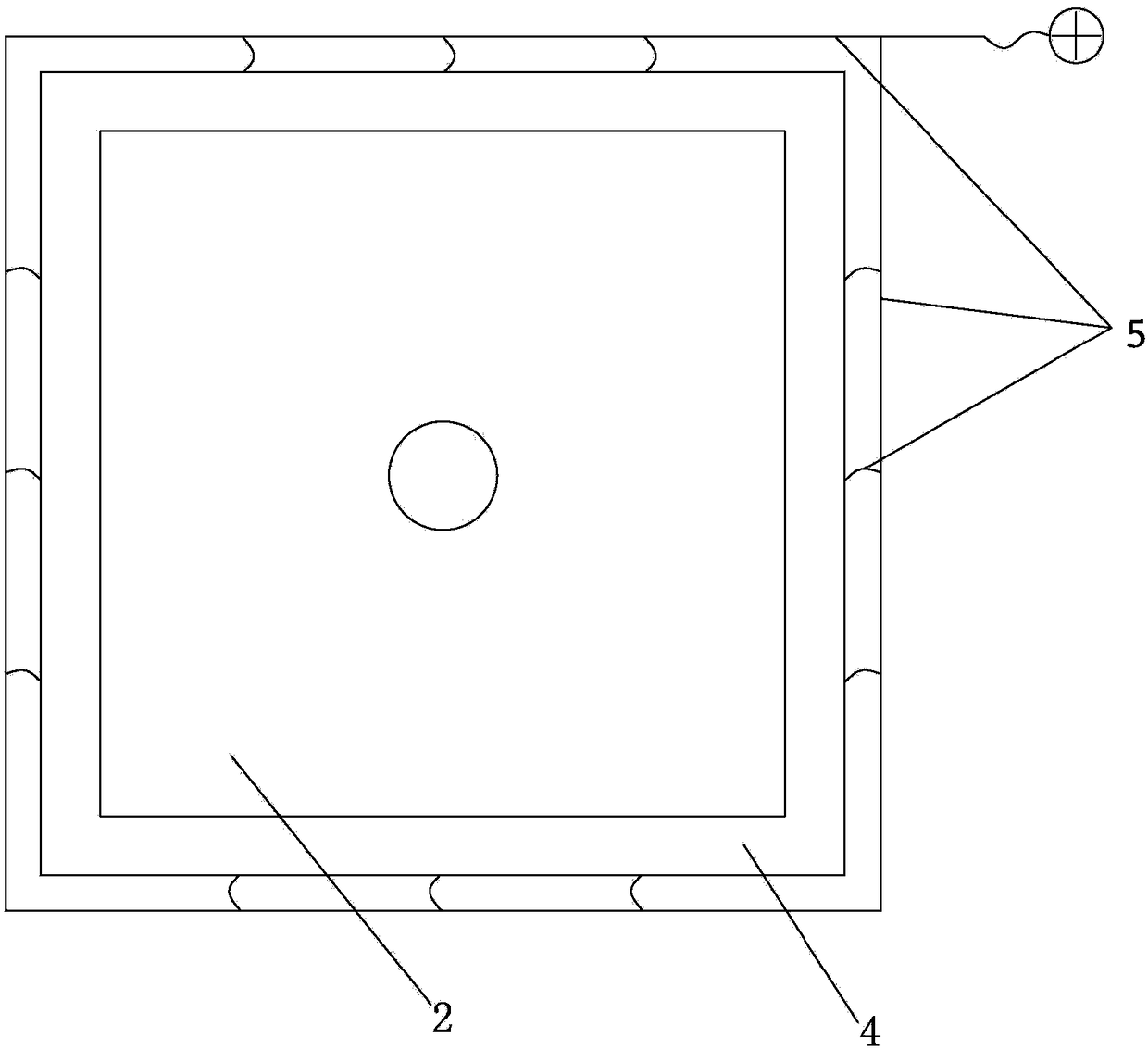

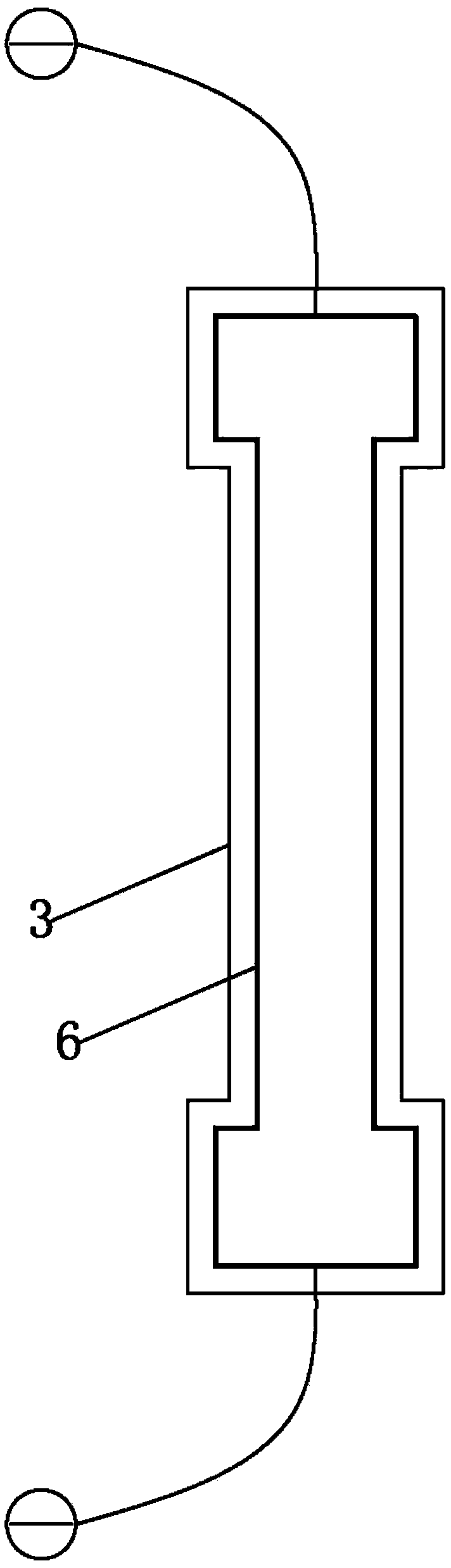

[0062] like figure 1 , figure 2 As shown, the graphene conductive composite material filter cloth 2 of the present invention replaces the common filter cloth on the an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com