Chalcogenide glass and preparation method thereof

A technology of chalcogenide glass and substrate, applied in the coating and other directions, can solve the problem of easy cracking of diamond-like carbon films, and achieve the effects of excellent infrared optical properties, enhanced environmental tolerance, and easy cracking or peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

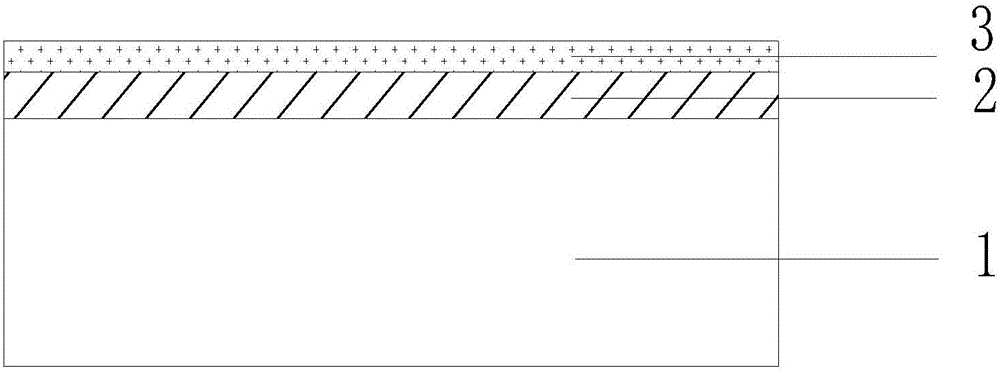

[0024] Prepare and clean the chalcogenide glass matrix Ge of the international general designation IG5 that meets the following performance requirements 28 Sb 12 Se 60 : The above-mentioned chalcogenide glass substrate 1 is in the shape of a flat sheet, with a size of 30×30×4 mm, and a transmission range of 0.8 μm-15 μm. Transmittance ≥ 60%, the density of the above-mentioned chalcogenide glass matrix is 4.67g·cm -3 , Vickers hardness 221±5gf / mm 2 , glass transition temperature 285±5℃;

[0025] The above-mentioned chalcogenide glass matrix Ge 28 Sb 12 Se 60 Wipe it clean, place the chalcogenide glass substrate that meets the purification technical requirements on the substrate holder of the magnetron sputtering equipment, install the high-purity germanium target, and pump the vacuum chamber pressure to 8.5×10 -4 Pa, fill the vacuum chamber with high-purity argon to 5×10 -1 Pa; heat the above-mentioned chalcogenide glass substrate to 80°C and keep it warm for 30min; t...

Embodiment 2

[0028] Prepare and clean the original matrix of chalcogenide glass Ge 12 As 33 Se 55 : The original matrix of the above-mentioned chalcogenide glass is a planar sheet, and its transmission range is 0.8 μm-15 μm when the thickness is 4 mm. Rate≥50%, Vickers hardness 217±5gf / mm 2 ;

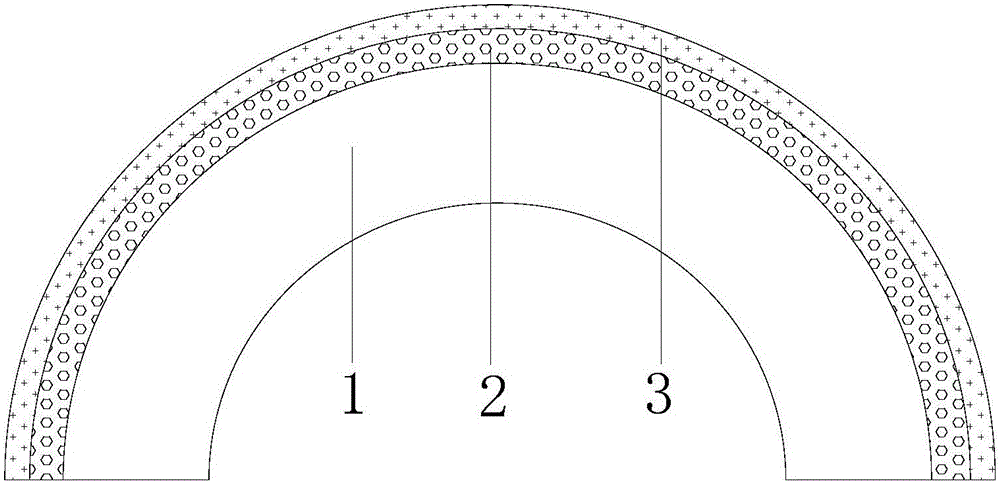

[0029] The above-mentioned chalcogenide glass original matrix Ge 12 As 33 Se 55 Processed into A spherical lens with a thickness of 1.0 mm and an outer diameter of 37.5 mm, using the above-mentioned spherical lens as a chalcogenide glass substrate 1; the smoothness of the above-mentioned chalcogenide glass substrate 1 is P=Ⅲ~Ⅴ, aperture N=3, △N=0.5, parallel Degree = 3′~5′; wipe the above-mentioned chalcogenide glass substrate clean, and after the Kazakh gas method inspection meets the purification technical requirements, put the above-mentioned chalcogenide glass substrate that meets the purification requirements into the magnetron sputtering equipment, and vacuumize to 8.5× 10 -4 Pa, fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com