PP-based tab material and preparation method thereof

A technology of base and acetylene carbon black, which is applied in the direction of conductive materials, electrical components, circuits, etc. dispersed in non-conductive inorganic materials, can solve problems such as tab corrosion, and achieve extended service life, high electrical conductivity, and high thermal conductivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

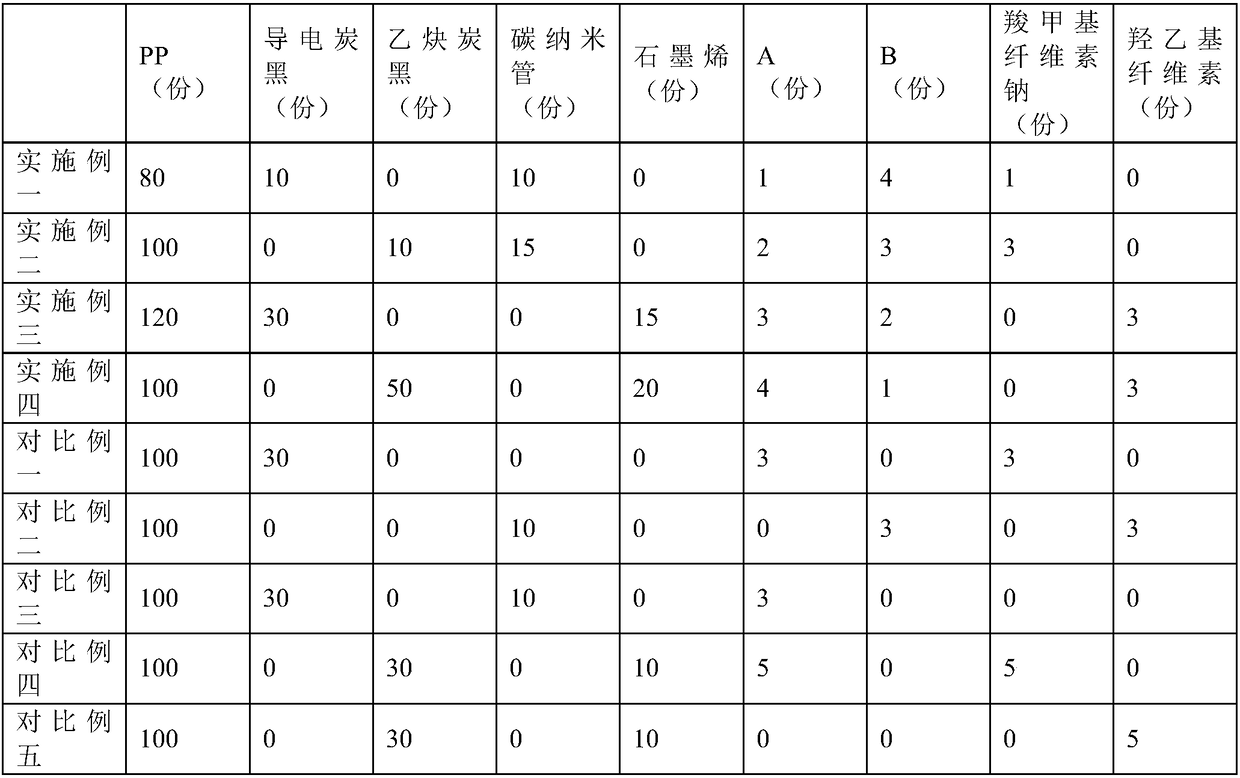

[0033] The present invention is described in further detail below in conjunction with embodiment.

[0034] Preparation:

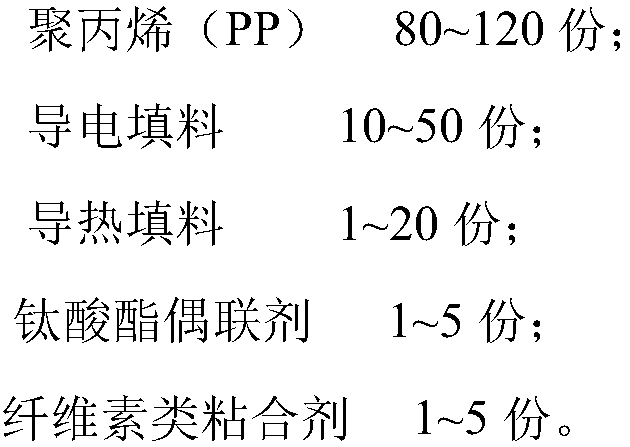

[0035] (1) Dosing according to PP, conductive filler, thermal conductive filler, titanate coupling agent, cellulose binder;

[0036] (2) drying the conductive filler and thermal conductive filler at a temperature of 110°C;

[0037] (3) After PP is melted at a high temperature of 190°C on an open mill, the conductive filler, thermal conductive filler, titanate coupling agent, and cellulose binder pretreated in step (2) are added for blending;

[0038] (4) peel off the blended mixture from the mill, and wait for it to cool to room temperature;

[0039] (5) The cooled mixture is pulverized at a high speed using a pulverizer, and the pulverized powder is used for tableting.

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com